7

Section 250-0200

SM 1985 Rev 1 11-00

Braking System - Air Drier

AIR DRIER DIAGNOSIS

The following table lists some of the conditions which

could prove responsible for air drier malfunctioning.

The reasons and remedies to correct these conditions

are listed opposite each condition.

WARNING

Always shut off the engine, completely drain

the air system, and make sure the air drier is

completely purged of all air pressure before

loosening air lines or fittings to prevent

personal injury.

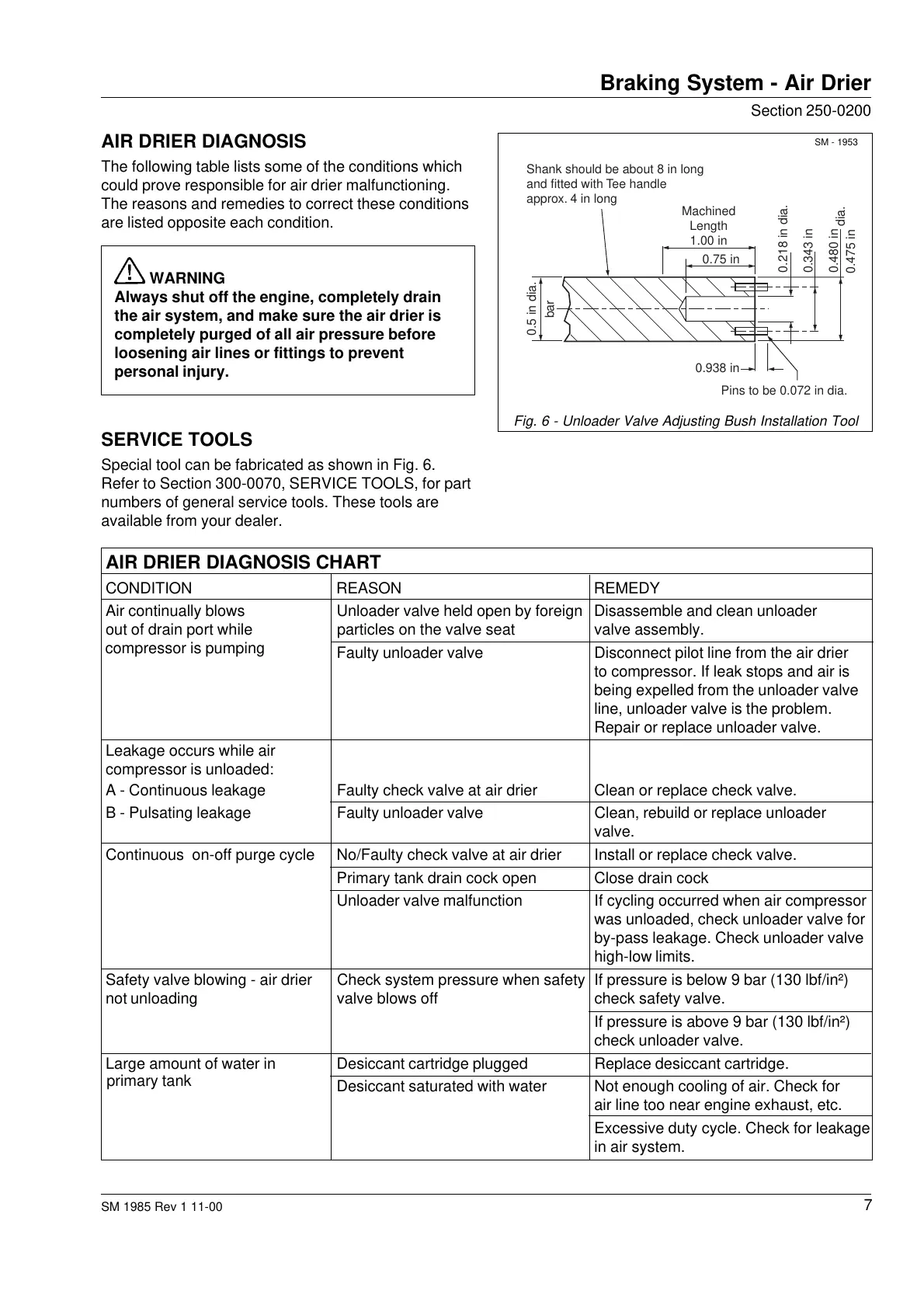

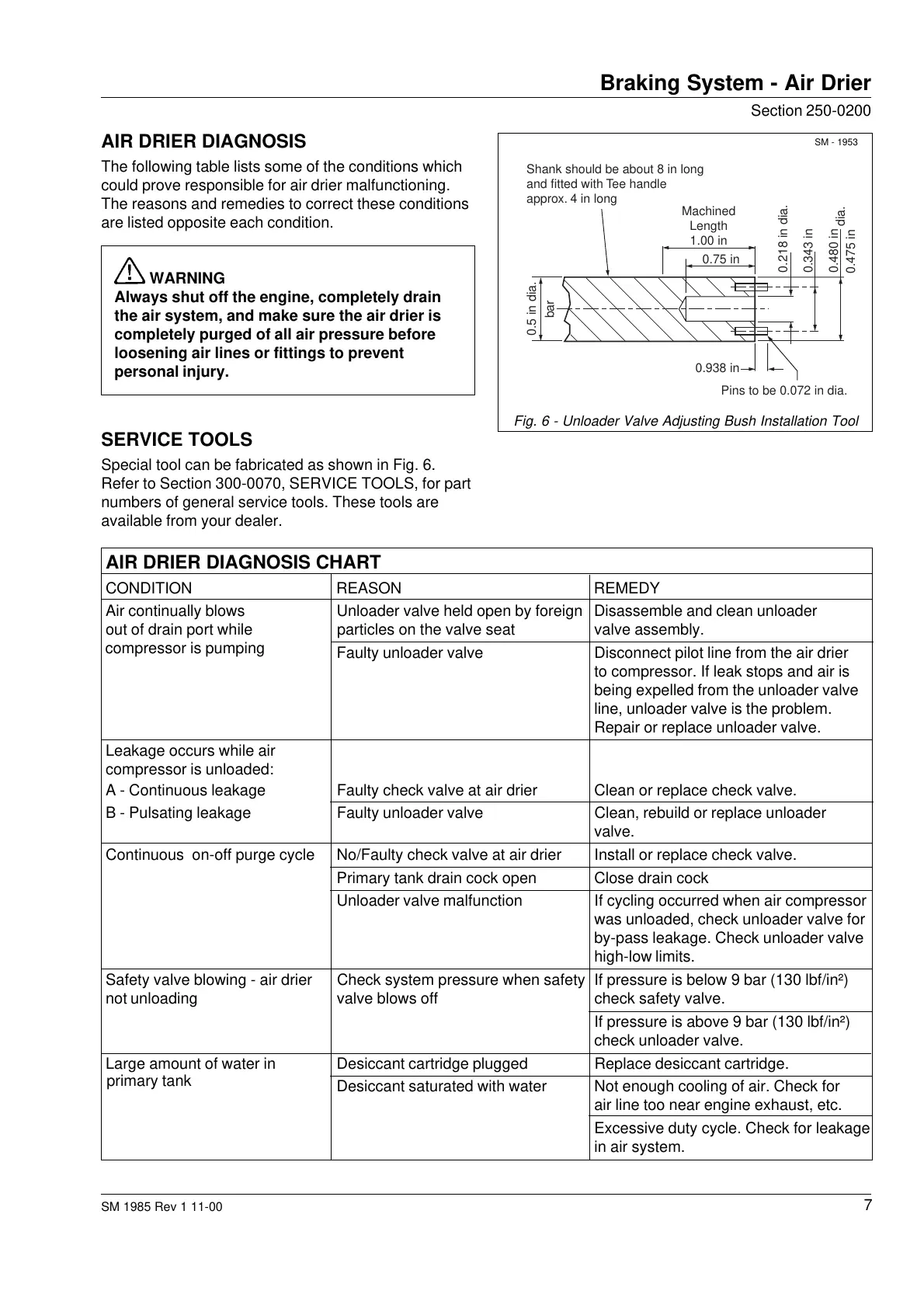

SERVICE TOOLS

Special tool can be fabricated as shown in Fig. 6.

Refer to Section 300-0070, SERVICE TOOLS, for part

numbers of general service tools. These tools are

available from your dealer.

Fig. 6 - Unloader Valve Adjusting Bush Installation Tool

SM - 1953

Machined

Length

1.00 in

0.75 in

0.938 in

Pins to be 0.072 in dia.

0.5 in dia.

bar

0.218 in dia.

0.343 in

0.480 in

0.475 in

dia.

Shank should be about 8 in long

and fitted with Tee handle

approx. 4 in long

AIR DRIER DIAGNOSIS CHART

CONDITION REASON REMEDY

Air continually blows Unloader valve held open by foreign Disassemble and clean unloader

out of drain port while particles on the valve seat valve assembly.

Faulty unloader valve Disconnect pilot line from the air drier

to compressor. If leak stops and air is

being expelled from the unloader valve

line, unloader valve is the problem.

Repair or replace unloader valve.

Leakage occurs while air

compressor is unloaded:

A - Continuous leakage Faulty check valve at air drier Clean or replace check valve.

B - Pulsating leakage Faulty unloader valve Clean, rebuild or replace unloader

valve.

Continuous on-off purge cycle No/Faulty check valve at air drier Install or replace check valve.

Primary tank drain cock open Close drain cock

Unloader valve malfunction If cycling occurred when air compressor

was unloaded, check unloader valve for

by-pass leakage. Check unloader valve

high-low limits.

Safety valve blowing - air drier Check system pressure when safety If pressure is below 9 bar (130 lbf/in²)

not unloading valve blows off check safety valve.

If pressure is above 9 bar (130 lbf/in²)

check unloader valve.

Large amount of water in Desiccant cartridge plugged Replace desiccant cartridge.

Desiccant saturated with water Not enough cooling of air. Check for

air line too near engine exhaust, etc.

Excessive duty cycle. Check for leakage

in air system.

compressor is pumping

primary tank

Courtesy of Machine.Market

Loading...

Loading...