Section 120-0010

Transmission - Transmission and Mounting

SM 1965 4-00

2

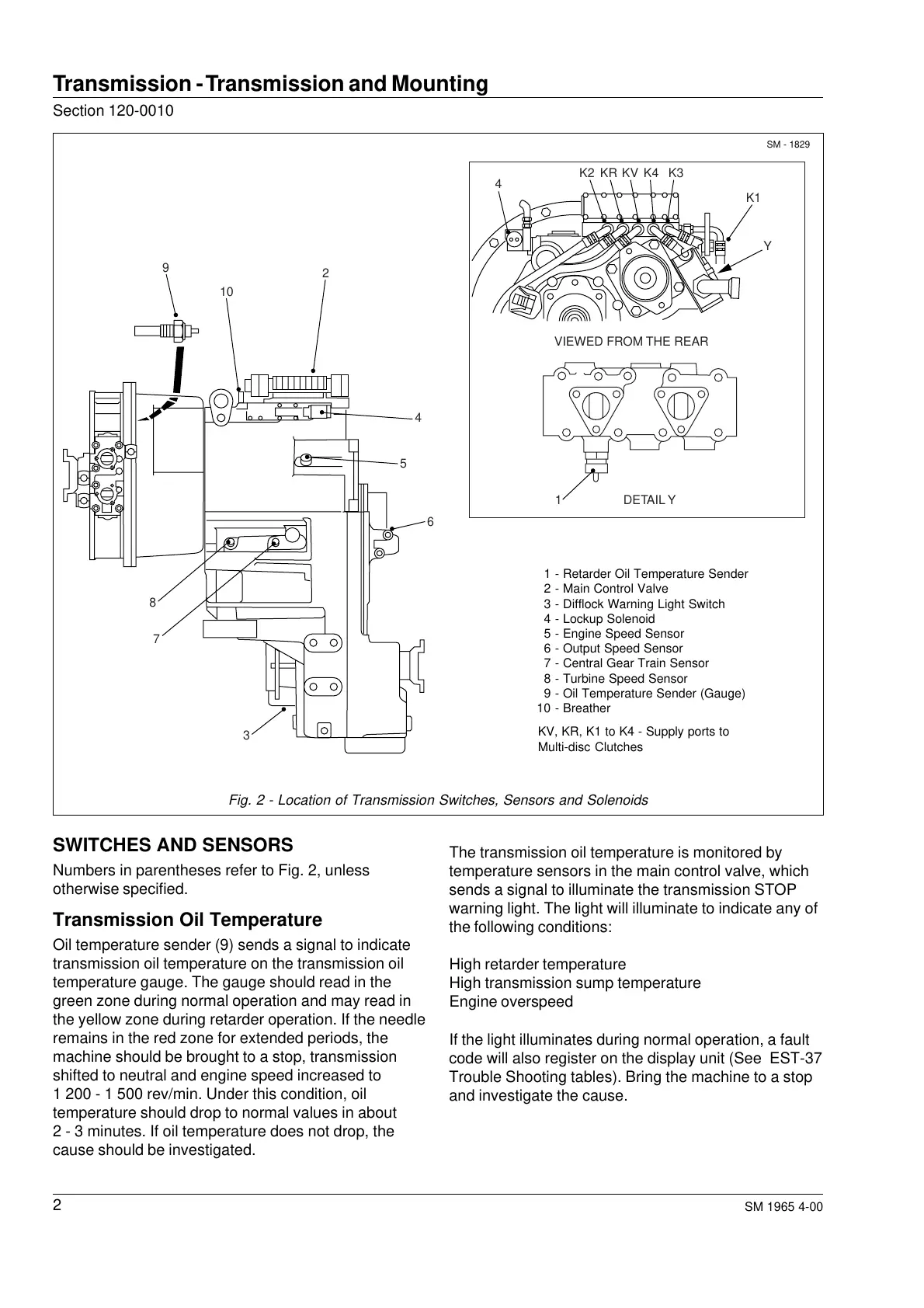

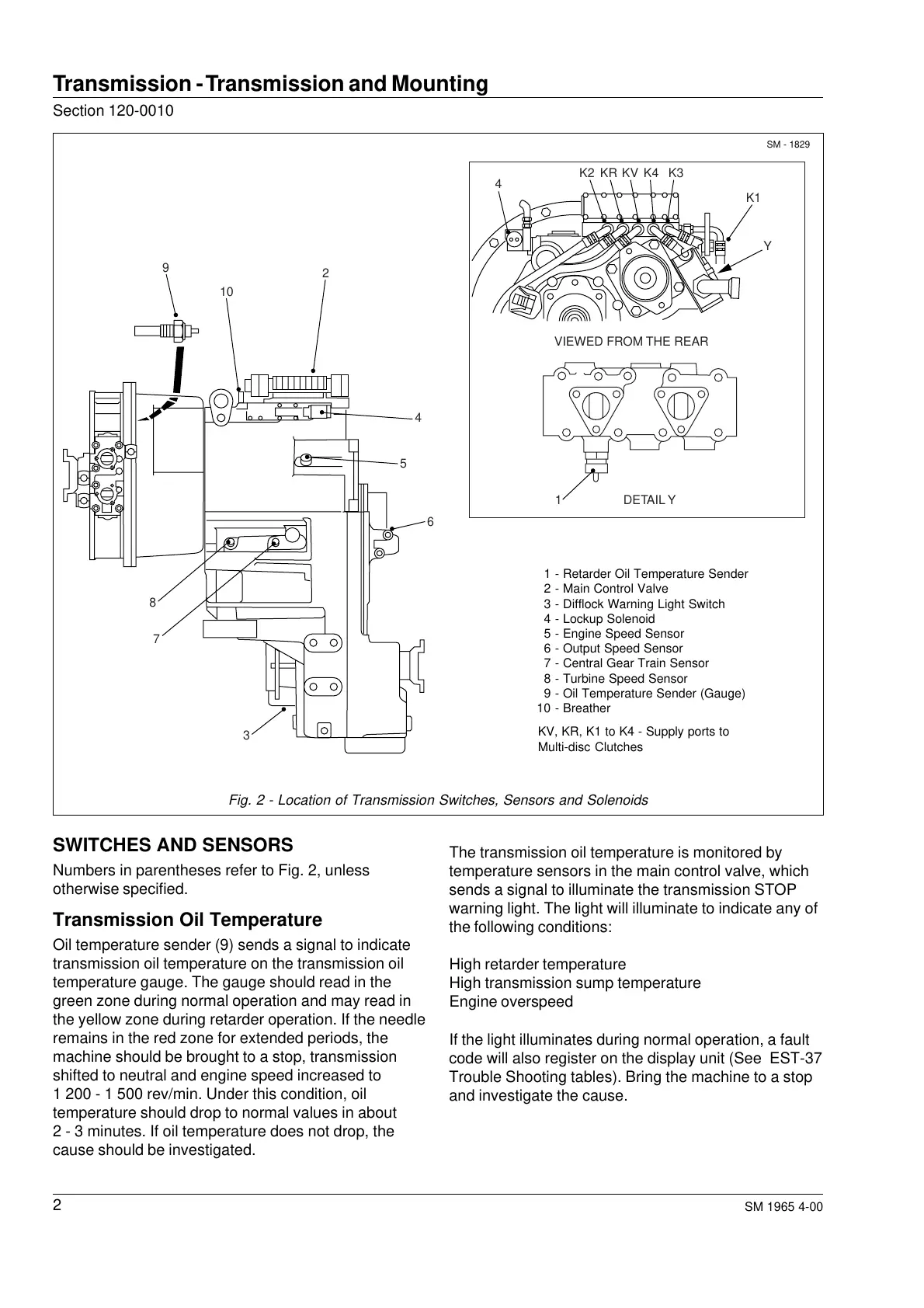

Fig. 2 - Location of Transmission Switches, Sensors and Solenoids

SM - 1829

SWITCHES AND SENSORS

Numbers in parentheses refer to Fig. 2, unless

otherwise specified.

Transmission Oil Temperature

Oil temperature sender (9) sends a signal to indicate

transmission oil temperature on the transmission oil

temperature gauge. The gauge should read in the

green zone during normal operation and may read in

the yellow zone during retarder operation. If the needle

remains in the red zone for extended periods, the

machine should be brought to a stop, transmission

shifted to neutral and engine speed increased to

1 200 - 1 500 rev/min. Under this condition, oil

temperature should drop to normal values in about

2 - 3 minutes. If oil temperature does not drop, the

cause should be investigated.

The transmission oil temperature is monitored by

temperature sensors in the main control valve, which

sends a signal to illuminate the transmission STOP

warning light. The light will illuminate to indicate any of

the following conditions:

High retarder temperature

High transmission sump temperature

Engine overspeed

If the light illuminates during normal operation, a fault

code will also register on the display unit (See EST-37

Trouble Shooting tables). Bring the machine to a stop

and investigate the cause.

4

1

K2 KR KV K4 K3

K1

Y

9

10

2

4

5

6

8

3

7

VIEWED FROM THE REAR

DETAIL Y

1 - Retarder Oil Temperature Sender

2 - Main Control Valve

3 - Difflock Warning Light Switch

4 - Lockup Solenoid

5 - Engine Speed Sensor

6 - Output Speed Sensor

7 - Central Gear Train Sensor

8 - Turbine Speed Sensor

9 - Oil Temperature Sender (Gauge)

10 - Breather

KV, KR, K1 to K4 - Supply ports to

Multi-disc Clutches

Courtesy of Machine.Market

Loading...

Loading...