Chassis - Chassis, Hood and Fenders

Section 100-0010

2

SM 1570 12-98

SM - 1958MAINTENANCE

Inspection

Inspect the frame and attached parts at intervals not

exceeding 250 hours for cracked or broken welds and

bending/twisting of the frame. Any defects found

should be repaired before they progress into major

failures. Contact your dealer for recommended weld

and repair instructions.

Welding

Note: It is important that the electrical connections are

disconnected in the following order to prevent damage

to the electrical components:

a. Disconnect battery equalizer ground cables.

b. Disconnect battery cables from terminal posts

(ground cable first).

c. Disconnect battery equalizer positive cables.

d. Disconnect electrical connections at the ECU.

After welding, reconnect all of the above in the reverse

order.

WARNING

Welding and flame cutting cadmium plated

metals produce odourless fumes which are

toxic. Recommended industrial hygiene

practice for protection of the welding operator

from the cadmium fumes and metallic oxides

requires enclosure ventilation specifically

designed for the welding process. A respiratory

protective device such as the M.S.A. 'Gasfoe'

respirator with G.M.A. cartridge will provide

protection against cadmium, fumes and

metallic oxides. The 'Gasfoe' respirator has

been approved by the U.S. Bureau of Mines:

Approval number

23B-10, and is designed to protect against

gases, vapours, and/or metal fumes.

Electric arc welding is recommended for all chassis

welding. Since the nature and extent of damage to the

frame cannot be predetermined, no definite repair

procedure can be established. As a general rule

however, if parts are twisted, bent or pulled apart, or a

frame is bent or twisted, no welding should be done

until the parts are straightened or realigned.

Successfully welded repairs will depend to a great

extent upon the use of the proper equipment, materials

and the ability of the welder. The Service Department

can be consulted regarding the feasibility of welding

repairs.

Painting

A check of the condition of the paint should be made

approximately twice a year and chassis repainted if

necessary.

WARNING

Welding, burning, heating or dressing surfaces

previously painted using polyurethane paint

produces fumes which are toxic. Surfaces must

be prepared using paint stripper prior to area

being reworked. Recommended Industrial

Hygiene and Safety Rules should be be

followed for protection of the welding operator

from fumes.

If painting of the actual frame of the unit is required,

thoroughly clean the areas to be painted. Apply a

primer coat of red oxide and then a finish coat of

polyurethane enamel.

To keep rust and corrosion to a minimum, periodic

painting of abrasions and other exposed metal areas on

the frame is highly recommended.

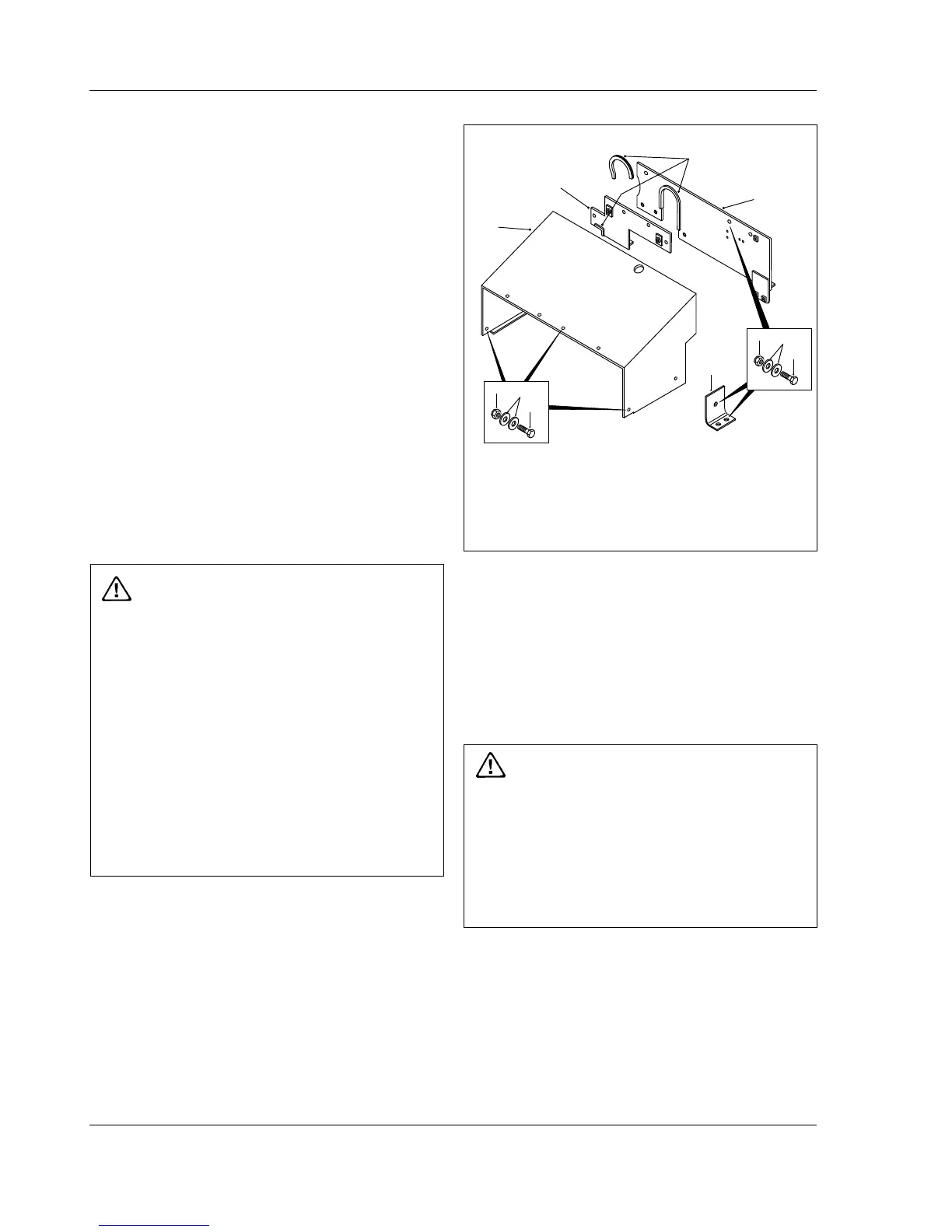

Fig. 2 - Exploded View of Hood and Mounting

1 - Hood Assembly

2 - Plate

3 - Bolt

4 - Hardened Washer

5 - Nut

6 - Baffle

7 - Baffle

8 - Beading

5

4

3

2

5

4

3

1

7

8

6

Loading...

Loading...