1.5

1.6

ALUMA

SHIELD

CABLE

DIE

DIE

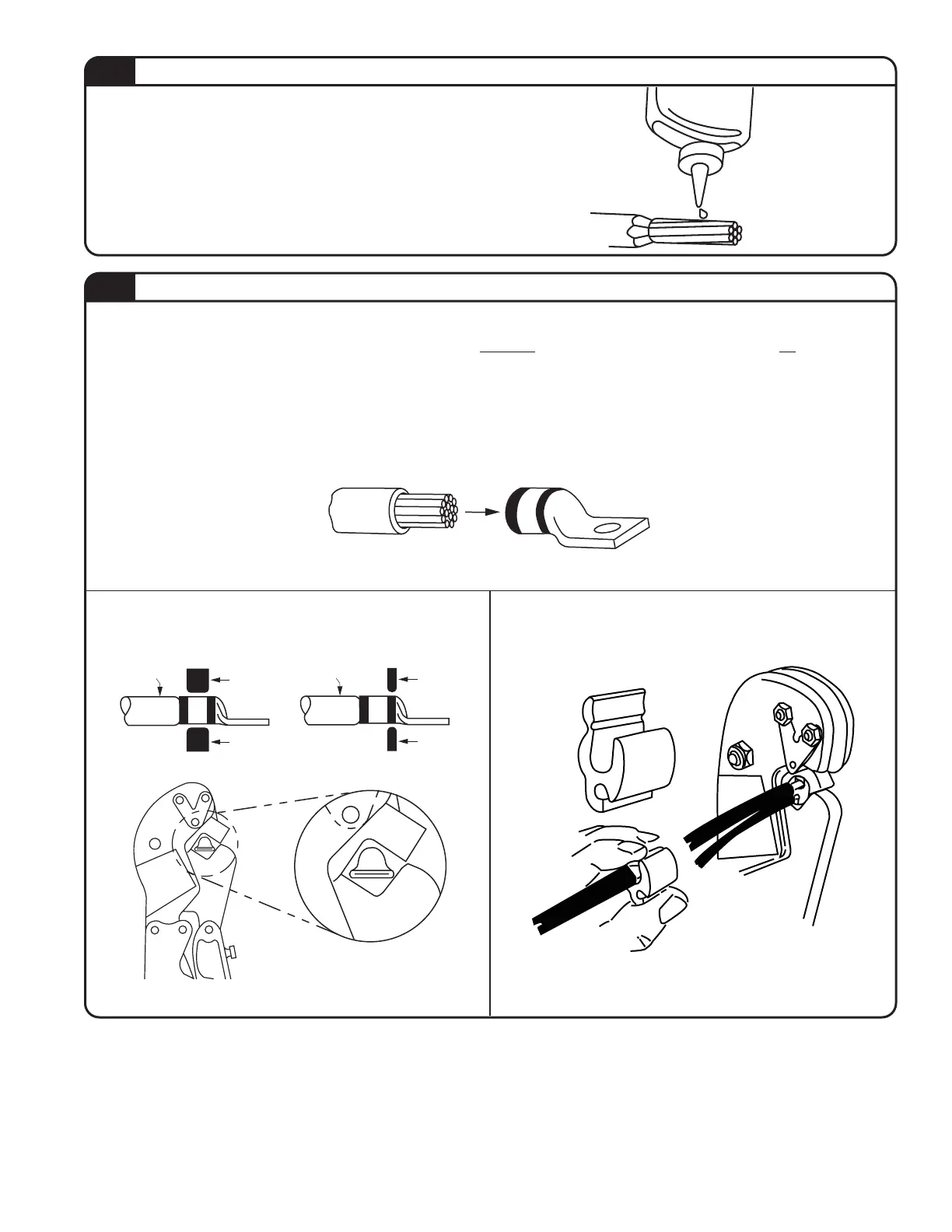

1. Insert prepared conductor into connector.

2. Locate connector in die grooves of tool, so the die is between the color code marks for copper and on the color

code marks for aluminium, see graphics below.

3. Some connectors require more than one compression. Refer to the instruction sheet supplied with the connectors

regarding the number of compressions required. If more than one compression is indicated, the fi rst compression

should be in the indicated area nearest to the tongue of a terminal and nearest the center of a splice, and then

working progressively toward the end of the barrel.

4. Close handles of tool completely for each compression.

STEP 1

CABLE

DIE

DIE

TYPICAL COPPER

INSTALLATION

STEP 2 STEP 3

TYPICAL ALUMINUM

INSTALLATION

TA01978 C Page 3 of 6

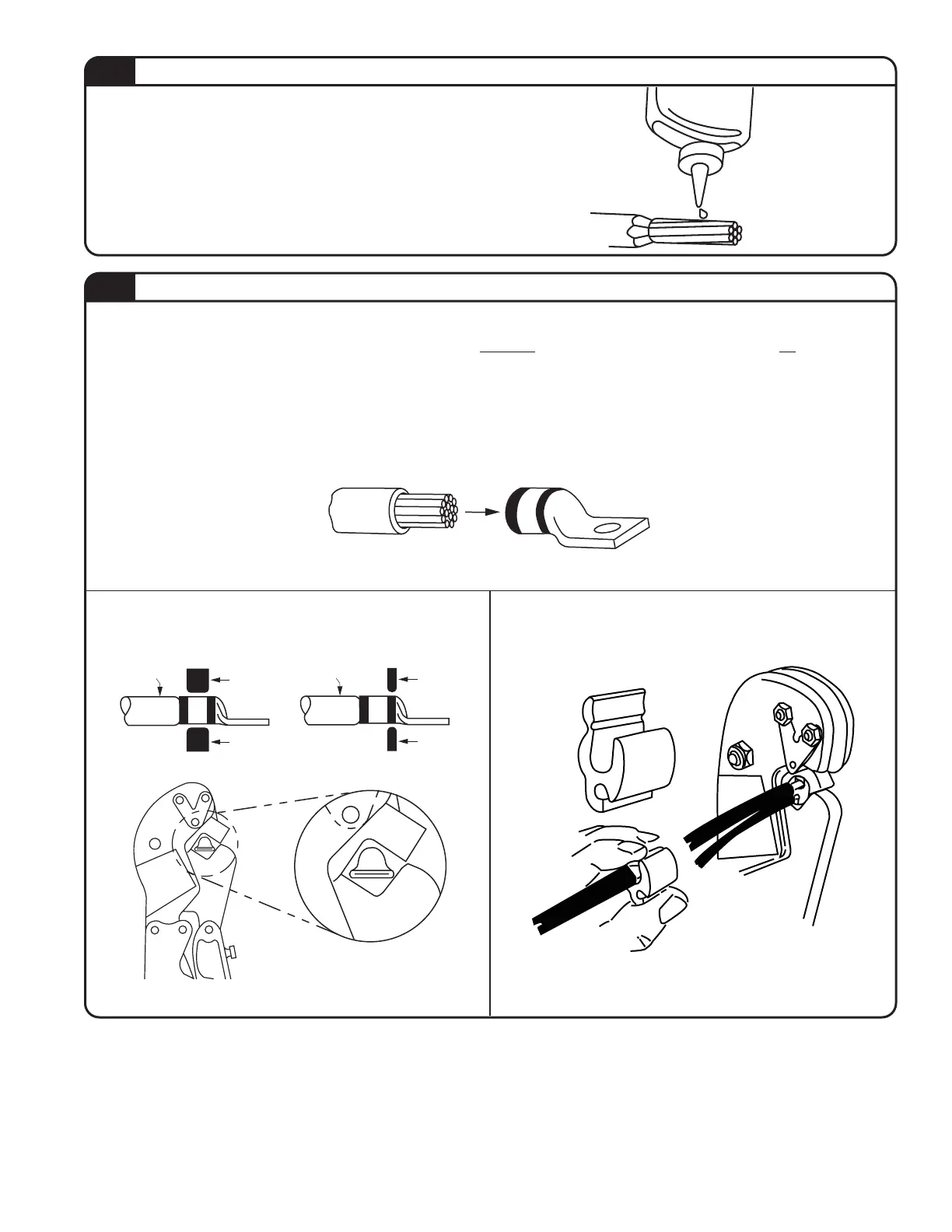

1. Strip insulation properly without cutting or nicking

the conductor strands. Refer to the instruction sheet

supplied with the connectors regarding strip length.

2. For aluminum conductor, smear a thin layer of joint

compound onto the cable and brush it in with a wire

brush or emery cloth.

MAKING A COMPRESSION

PREPARING THE CONDUCTOR

Loading...

Loading...