3.0

3.1

VISUAL INSPECTION

3.3

GAGING PROCEDURE

CALIBRATION VERIFICATION

3.2

HANDLE SPREAD CHECK

RAM JUST

TOUCHING DIE

ADJUSTING SCREW

MEASURE

HERE

HANDLE

A

RETAINING SCREW

LOCK SCREW

FLAT SURFACE OR

TABLE TOP

DIE

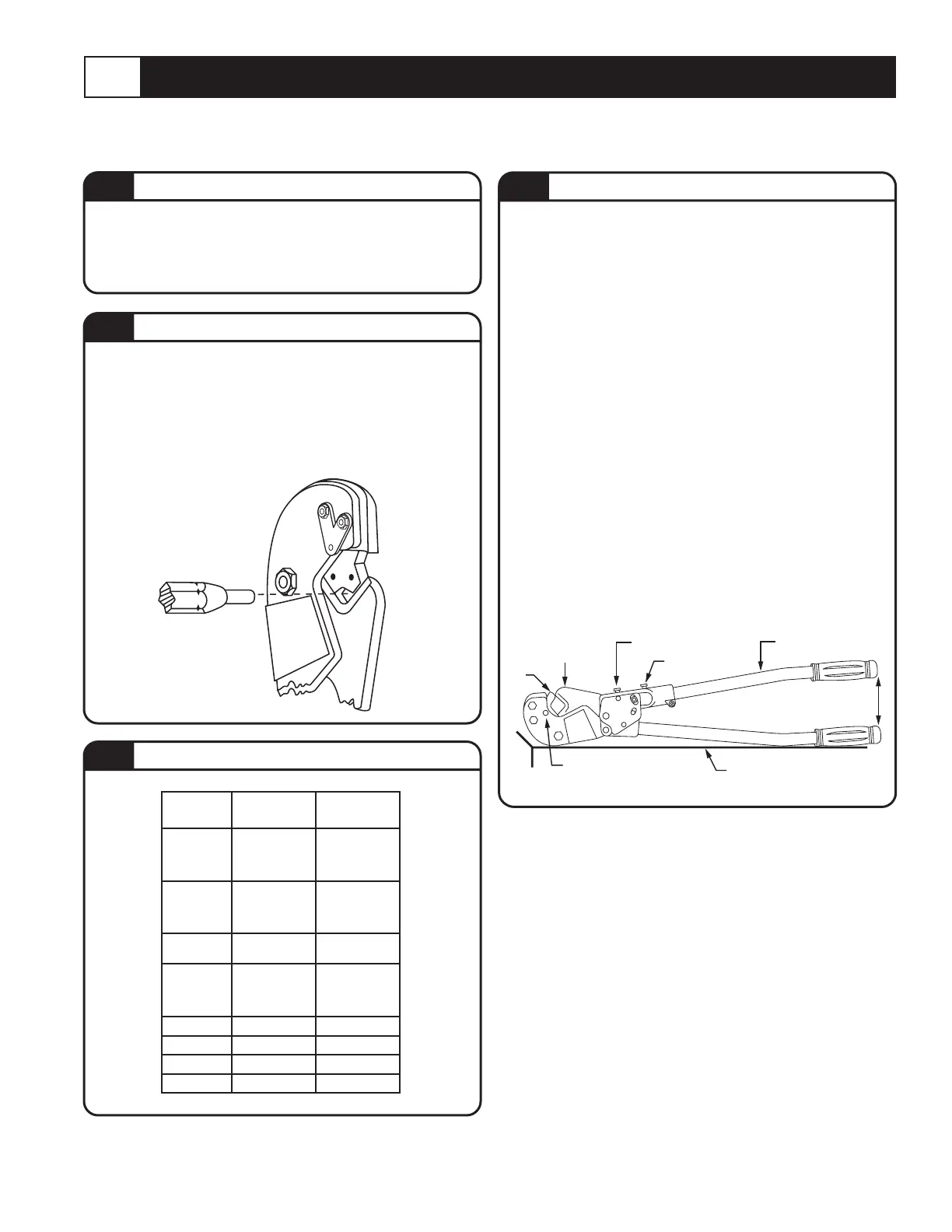

To ensure the tool will produce a reliable

compression, the tool must be properly adjusted.

CHECKING TOOL ADJUSTMENT

1. Insert die in place.

2. Lay tool on a fl at surface. Open handle A and

allow it to close under its own weight. The ram

should be touching the die.

3. Measure distance between handle grips. In

a properly adjusted tool, the distance should

be between 11” and 14”. If it is less than 11”

or more than 14”, the tool needs adjustment.

(See graphic below).

ADJUSTING TOOL

1. Loosen lockscrew.

2. To increase distance between handles, turn

adjusting screw clockwise.

3. To decrease distance between handles, turn

adjusting screw counterclockwise.

4. Tighten lock screw.

5. Recheck handle distance. Adjust again, if

necessary.

NOTE: Calibration verifi cation of the tool should be performed whenever damage or suspected damage has occurred or as

often as operating conditions warrant.

TA01978 C Page 5 of 6

1. Tool must be free of cracks, sharp edges and

other obvious imperfections that may affect

performance of the tool. Nest area must be free

of burrs, dents or scratches.

NOTE: Wipe dies before gaging.

1. Squeeze handles until jaws are fully closed.

2. Select gage pin which can be inserted into nest

with minimal hand pressure. See graphic below.

3. Gage pin should fall between the limits shown on

tables in section 3.4.

GAGE PIN

GROOVE

COLOR

DIE

CAT. NO.

GAGING

MIN. - MAX.

RED

BLUE

GRAY

BROWN

13461

.165-.181

.181-.210

.230-.251

.260-.281

GREEN

PINK

BLACK

ORANGE

13462

.313-.335

.351-.371

.383-.406

.429-.454

PURPLE

YELLOW

13463

.480-.503

.529-.562

GOLD

TAN

OLIVE

RUBY

13464

.383-.406

.429-.454

.480-.503

.533-.553

WHITE 13465 .609-.632

RED 13466 .653-.677

BLUE 13467 .686-.710

BROWN 13468 .855-.883

3.4

GAGING TABLE

Loading...

Loading...