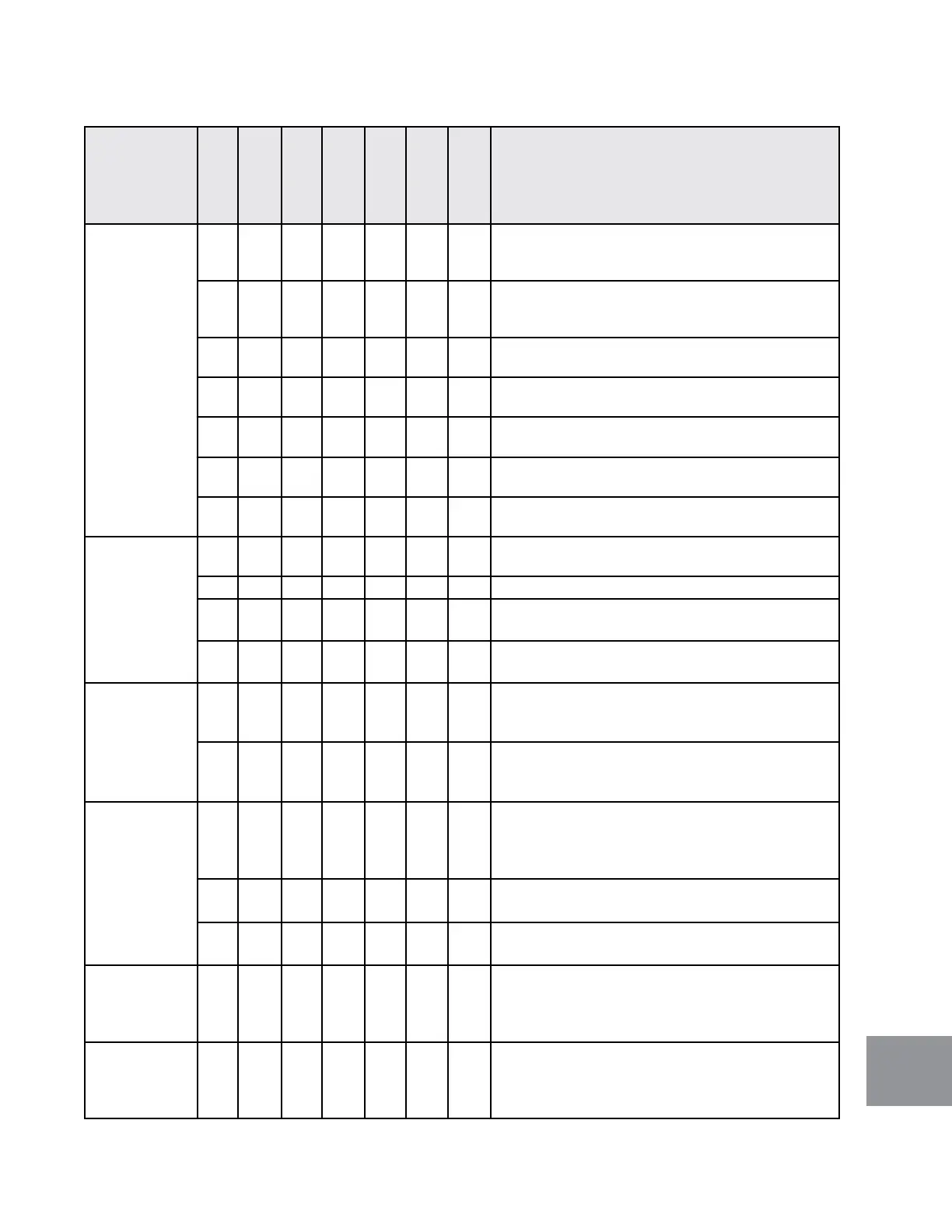

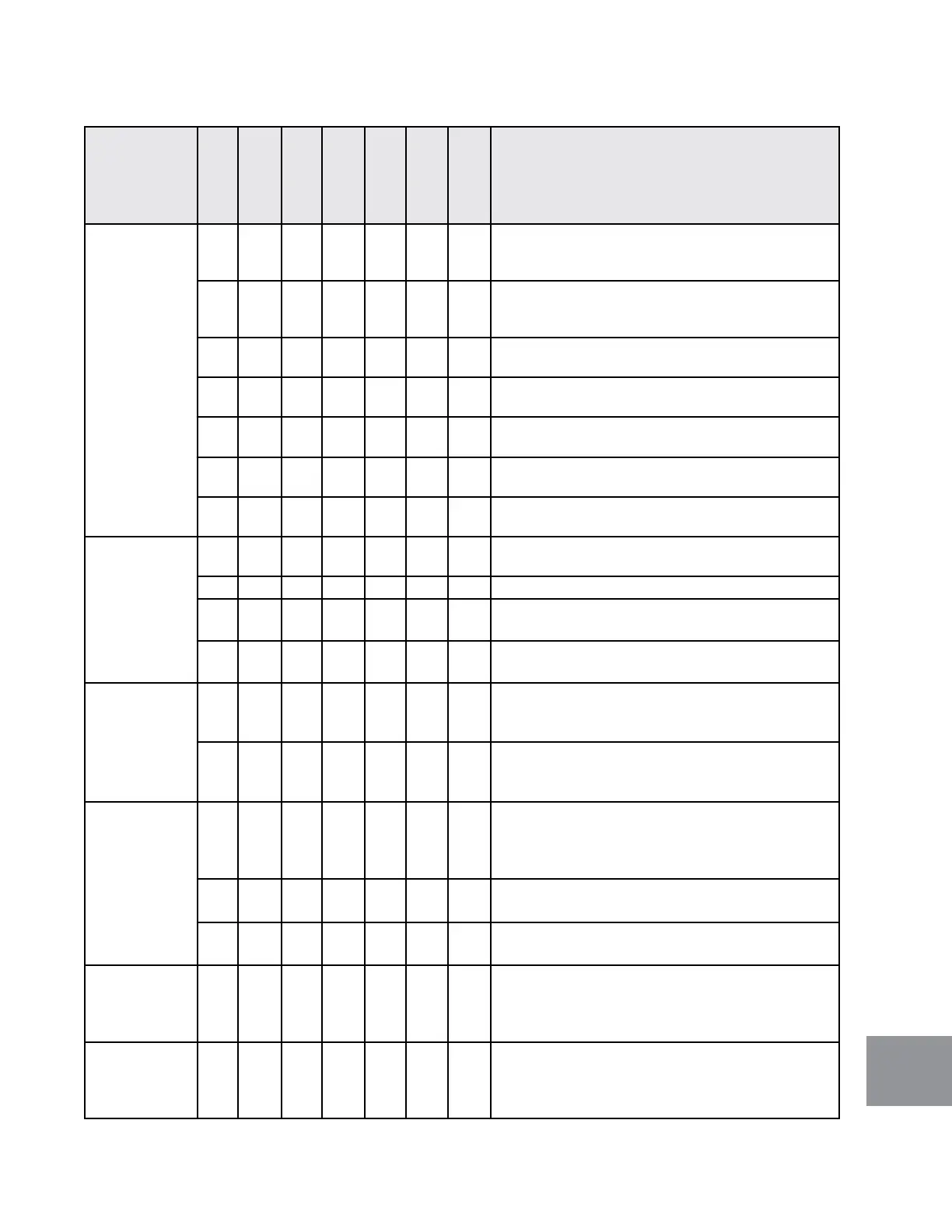

MAINTENANCE

THOR MOTOR COACH | MADE TO FIT

105

14

ITEM

EVERY TRIP

EVERY

MONTH

EVERY 3

MONTHS

EVERY 6

MONTHS

EVERY YEAR

PRIOR TO

STORAGE

AS REQUIRED

PROCEDURE TO BE PERFORMED:

Maintenance schedules are minimum requirements. Heavy

use, unusual temperatures or humidity, or other extreme

conditions may require more frequent maintenance.

Engine/Chassis x x x Check engine oil and top off with type recommended by chassis

manufacturer. Change oil and lter at recommended mileage

intervals.

x x Check uid levels including: brake, steering, coolant,

transmission, washer, etc. Top off reservoirs as needed with uids

recommended by chassis manufacturer.

x x Inspect underneath engine and transmission for leaks. Repair as

necessary.

x x Inspect air and fuel lters and replace at interval recommended by

chassis manufacturer.

x x Inspect chassis battery, terminals and cables. Repair and replace

as necessary.

x x Inspect suspension, steering components, exhaust systems etc.

Repair and replace as necessary.

x x Generator exhaust: inspect for cracks, blockages, damage.

Replace immediately if any faults are discovered.

Brakes x x x x Check uid levels. Top off reservoir as needed with uid specied by

chassis manufacturer and only from an unopened container.

x x Inspect pads and rotors. Replace as necessary.

x x x Inspect parking brake for proper function. Repair and replace as

necessary.

x x Inspect brake lights and turn signals for proper function. Repair

and replace components as needed.

Weight Distribution x x Check for proper weight distribution of equipment and

components. Place heavy items as near and over axles as

possible.

x Weigh loaded motorhome with vehicle scales to determine

loading. Do not overload vehicle per GAWR and GVWR ratings

(see manufacturers specications).

Tires x x Inspect for proper ination (PSI). Inate to proper cold pressure

(PSI). Inspect for wear. Repair or replace ONLY with tire(s) of

proper size and load rating. Unusual wear patterns indicate

problems that should be addressed by qualied technicians.

x x Check all wheel lug nuts and tighten using a properly calibrated

torque wrench. Torque per chassis manufacturers specications.

x x Inspect spare tire for proper ination (PSI). Inspect for cracking,

aging. Replace as necessary.

Wheel Alignment x Inspect tires for uneven wear, dents in the wheel rims, and if

vehicle steering seems unusual. All are indications that front

wheels need re-aligned. Align as needed with a fully loaded

vehicle and only by qualied technicians.

Exterior: mirrors,

vision systems

x x Inspect rear-view mirrors and adjust when needed. Replaced

broken mirrors and components promptly. Inspect rear and

side-view vision systems for proper operation. Repair and replace

components promptly.

Maintenance Schedule

Loading...

Loading...