MAINTENANCE

THOR MOTOR COACH | MADE TO FIT

107

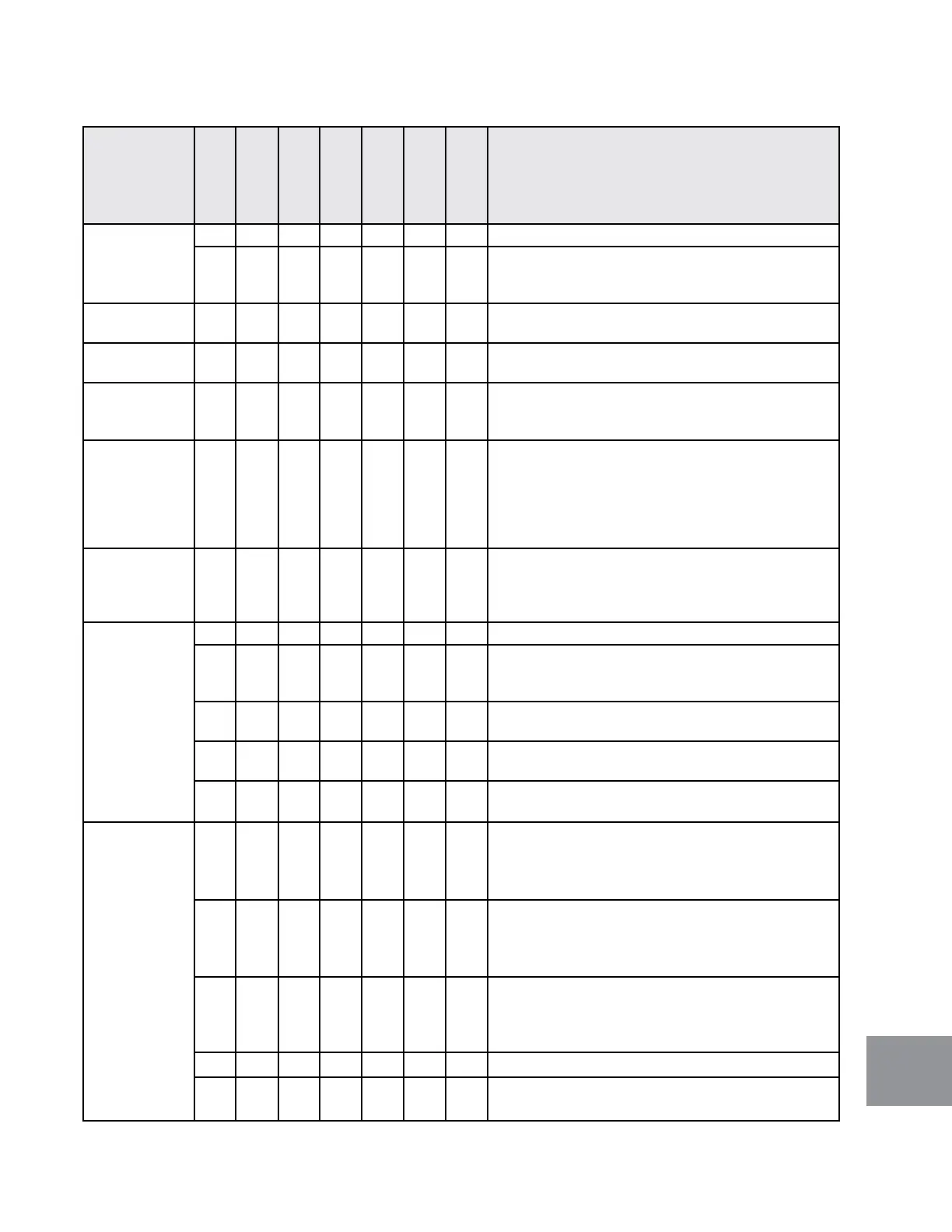

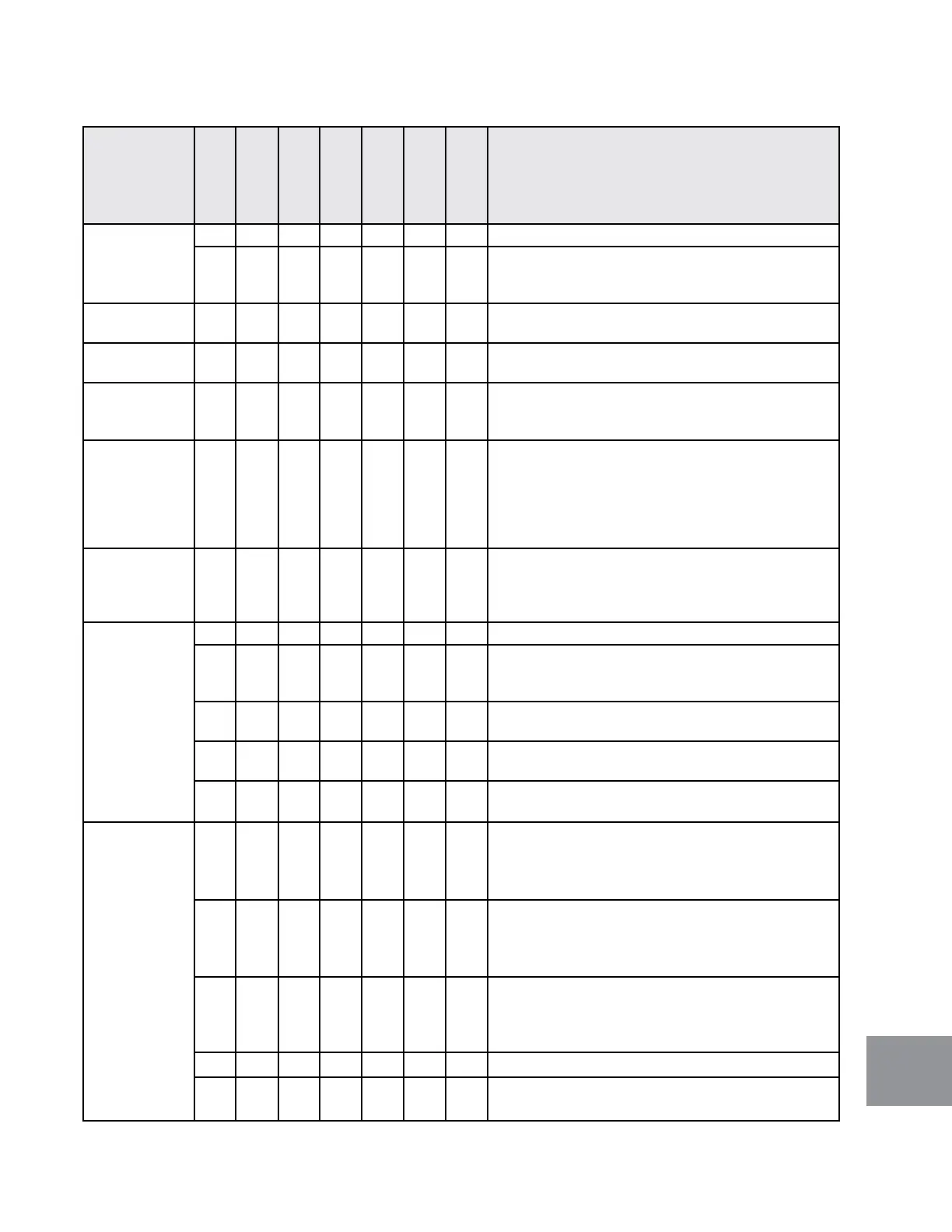

14

ITEM

EVERY TRIP

EVERY

MONTH

EVERY 3

MONTHS

EVERY 6

MONTHS

EVERY YEAR

PRIOR TO

STORAGE

AS REQUIRED

PROCEDURE TO BE PERFORMED:

Maintenance schedules are minimum requirements. Heavy

use, unusual temperatures or humidity, or other extreme

conditions may require more frequent maintenance.

Awnings: patio,

door, & window

x x Operate awnings to ensure proper functioning.

x x Clean awning fabric with warm water and mild detergent. Allow

fabric to dry before retracting. Lubricate hinges and joints with

silicone grease.

Awnings: slideout

topper

x x Inspect for proper operation, wear, or damage. Repair and replace

as needed.

Slideouts: electric x x Inspect and test for proper operation. Inspect gear tracks for

unusual wear. Lubricate per manufacturers recommendations.

Slideouts: hy-

draulic

x x Inspect and test for proper operation. Inspect rams and hydraulic

ttings and hoses for leaking uids. Top off reservoir with uid

recommended by manufacturer.

Leveling Jacks:

hydraulic

x x Inspect system for proper function. Ensure jack rams extend

properly and fully retract and stay retracted. Ensure jacks deploy

only when vehicle's transmission is in park and the parking brake

is engaged. Inspect hydraulic lines for leaks. Inspect hydraulic uid

reservoir, top off as needed with manufacturers recommended

uid.

Stabilizers: electric x x Ensure stabilizers deploy properly and fully retract. Clean

deployment mechanism with mild detergent and rinse with water.

Lightly lubricate as needed. Inspect jack pads for damage.

Replace worn or damaged components as needed.

Cab/Cockpit x x Vehicle horn: test for proper function, repair if defective.

x x Gauges and switches: ensure all vehicle control functions and

driver aids are in proper working order before every trip. Repair

and replace as needed.

x Cockpit seating: lubricate mechanisms, repair or replace damaged

seats or seating components.

x Engine cover gasket: Inspect for proper t and seal. Replace if

damaged.

x Inspect heater and air conditioner for proper function. Repair as

necessary.

Electrical System:

12 volt

x x Check and service auxiliary and chassis battery(ies). Add ONLY

distilled water as needed or replace batteries that fail to hold a charge.

Do not attempt to open maintenance-free batteries. Keep batteries on

trickle charge when stored for an extended period of time.

x x Check battery charging system: chassis alternator, inverter/

converter, solar controller. Ensure proper charging voltage

via multimeter reading (battery manufacturers charging

recommendations).

x x Multiplex system (if installed): check using ‘Hot Skin Test’; with a

multimeter set to 12 volts, place one probe on main panel and one

probe to a known ground. There should be no voltage. If voltage is

present, have multiplex system inspected by a qualied technician.

x x Interior 12 volt lighting: repair and replace as needed.

x Check 12 volt power plugs, USB ports and electronic device

charging stations. Repair or replace as needed.

Loading...

Loading...