Rev 19 Oct 2020

Page 3

Chapter 1 Overview

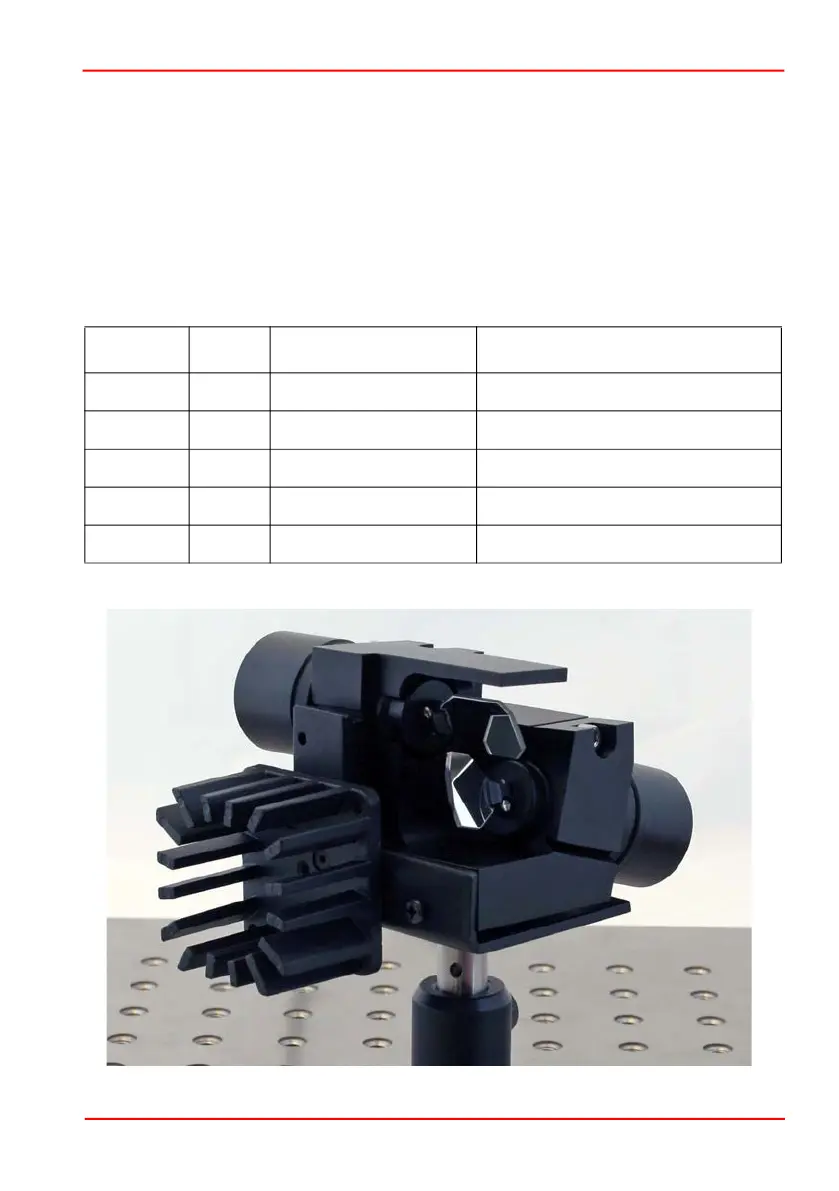

1.2.3 The Mirror

The mirror assembly is attached to the end of the actuator, and deflects the light beam

over the angular range of the motor shaft. Scanning galvo applications demand high

speed and frequencies of the shaft rotation, and so the inertia of the actuator and

mirror assembly can have a profound effect on the performance of the system. High

resonant frequencies and enhanced stiffness in the mirror assembly also add to

system performance by increasing bandwidth and response times.

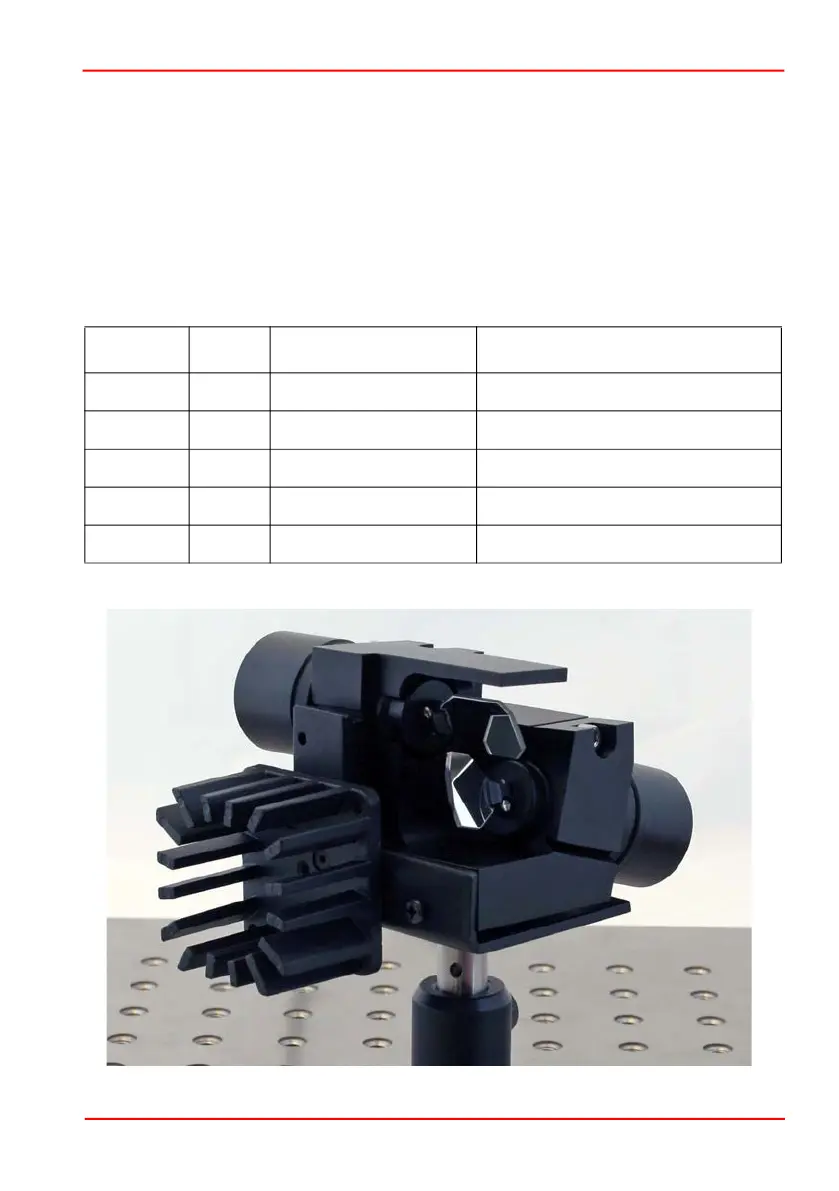

Wavelength ranges and damage threshold of the different mirror coatings are details

below:

.

Fig. 1.3 GVS012 Motor/Mirror Assembly with GHS003 Heatsink (available separately)

Part No Coating Wavelength Damage Threshold

GVS01x Silver 500 nm - 2.0 µm

3 J/cm

2

at 1064 nm, 10 ns pulse

GVS11x Gold 800 nm - 20.0 µm

2 J/cm

2

at 1064 nm, 10 ns pulse

GVS21x E02 400 nm - 750 nm

0.25 J/cm

2

at 532 nm, 10 ns pulse

GVS31x K13 532 nm and 1064 nm

5 J/cm

2

at 1064 nm, 10 ns pulse

GVS41x F01 250nm - 450nm

0.3 J/cm

2

at 355 nm, 10 ns, pulse

Loading...

Loading...