How to fix THORLABS GVS011 Scanner motor not responding?

- KKevin SullivanAug 2, 2025

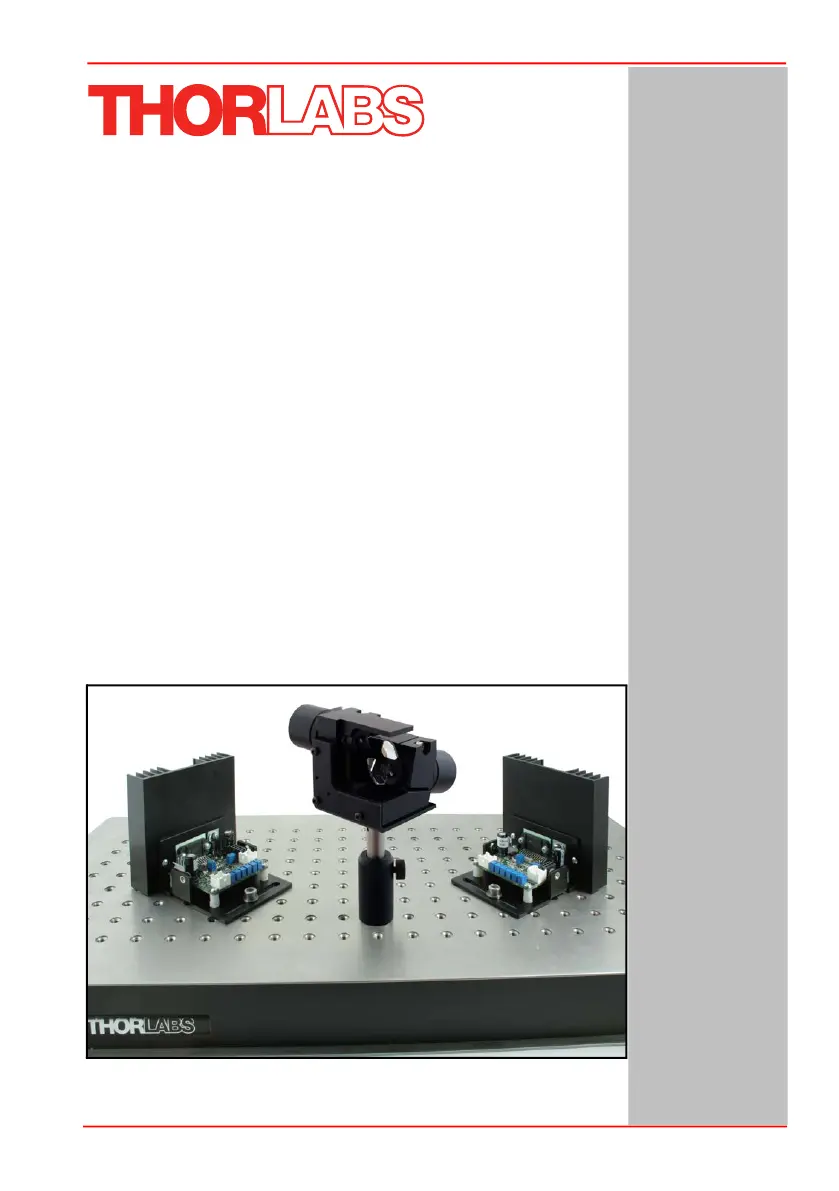

If the THORLABS Scanner motor isn't responding, ensure power is correctly applied to the board. Also, check for faulty or improperly connected cables. Try resetting the device to clear any faults. Finally, verify the device is not disabled by checking the jumper settings.