•

WHEEL

HOUR EEL

Disassembly

of

Movement

Cont'd.

FIGURE

I

FIGURE

2

FRICTION RING

CENTER WHEEL

The action

of

the

gear

train

is

as

follows:

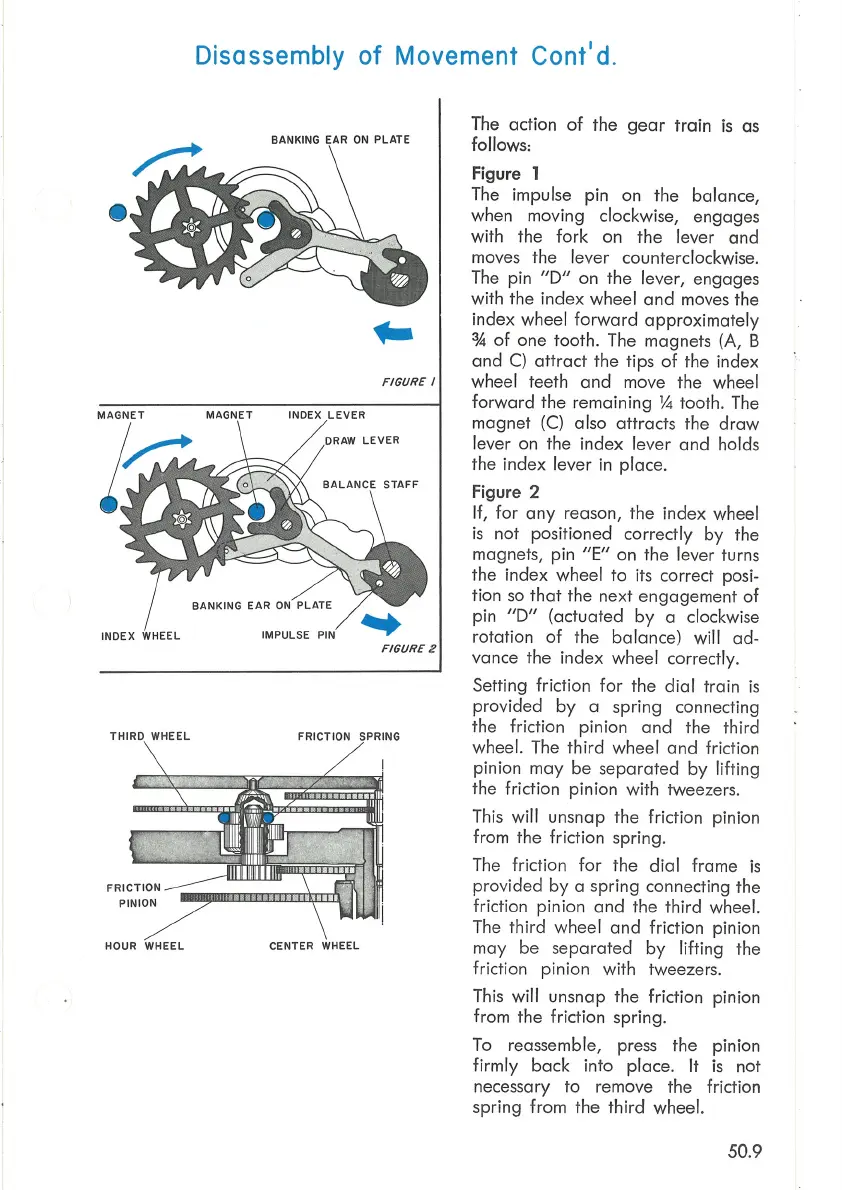

Figure

1

The impulse pin on the balance,

when moving clockwise, engages

with the

fork

on the lever and

moves the lever counterclockwise.

The

pin

"D"

on the lever, engages

with the index wheel

and

moves the

index wheel

forward

approximately

%

of

one tooth. The magnets (A, B

and

C)

attract

the tips

of

the index

wheel teeth

and

move the wheel

forward

the remaining

1,4

tooth. The

magnet

(C)

also attracts the

draw

lever on the index lever

and

holds

the index lever in place.

Figure 2

If,

for

any

reason, the index wheel

is

not positioned correctly

by

the

magnets, pin

"E"

on the lever turns

the index wheel

to

its correct posi-

tion

so

that

the next engagement

of

pin

"D"

(actuated

by

a clockwise

rotation

of

the balance) will

ad-

vance the index wheel correctly.

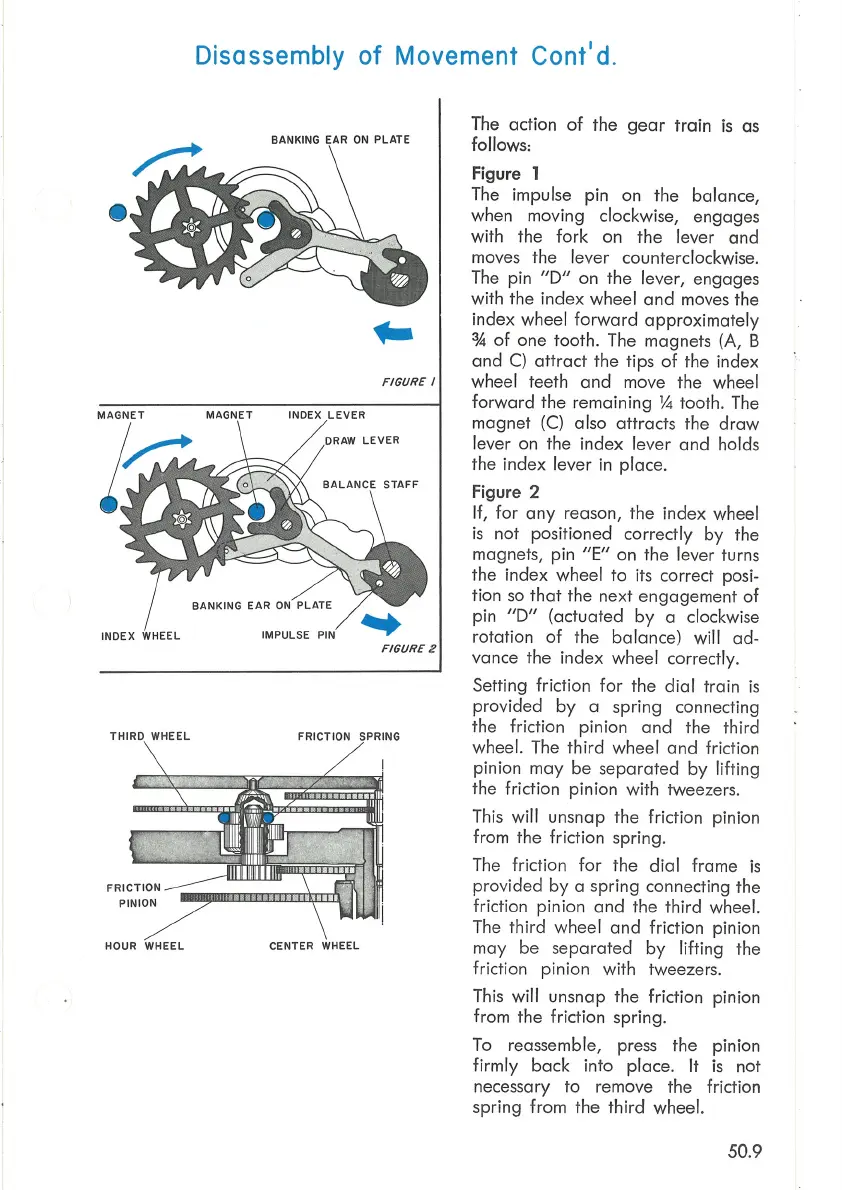

Setting friction

for

the

dial

train

is

provided

by

a spring connecting

the friction pinion

and

the third

wheel. The

third

wheel and friction

pinion

may

be separated

by

lifting

the friction pinion with tweezers.

This will unsnap the friction pinion

from the friction spring.

The

friction

for

the

dial

frame

is

provided

by

a spring connecting the

friction pinion

and

the

third

wheel.

The

third

wheel

and

friction pinion

may be separated

by

lifting the

friction pinion with tweezers.

This

will

unsnap the friction pinion

from the friction spring.

To

reassemble, press the pinion

firmly

back

into place.

It

is

not

necessary

to

remove the friction

spring from the

third

wheel.

50.9

Loading...

Loading...