NOTICE! If you don't do this adjustment, there's a risk that

the drawbar can loosen, or that operations can be louder than

normal.

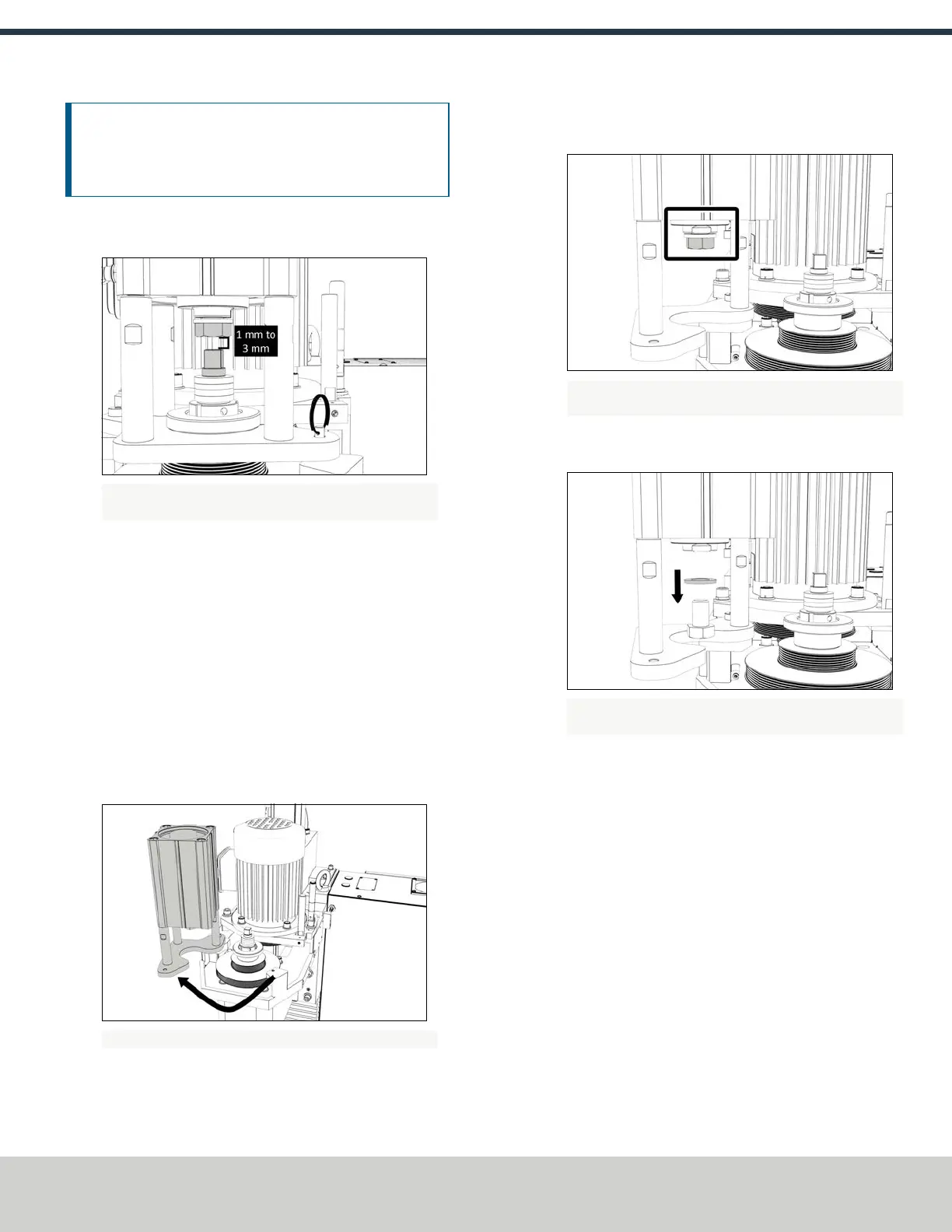

1. Examine the space between the hex head screw on the

Power Drawbar cylinder's rod and the top of the drawbar.

Figure 2-23: Example of a correctly spaced drawbar and

Power Drawbar cylinder.

2. Make sure that the gap is between 1 mm and 3 mm.

Depending on the size of the gap, do one of the following:

l If the gap is between 1 mm and 3 mm, you have

completed adjusting the initial setup.

l If the gap is less than 1 mm or greater than 3 mm, go to

Step 3.

3. Disconnect the shop's air supply from the Power Drawbar

button.

4. Pull out the quick-release pin.

5. Pivot the Power Drawbar cylinder assembly to the left so

that you can access the Power Drawbar cylinder's rod.

Figure 2-24: Power Drawbar cylinder pivoted to the left.

6. Use an adjustable wrench to remove the hex head screw on

the Power Drawbar cylinder’s rod.

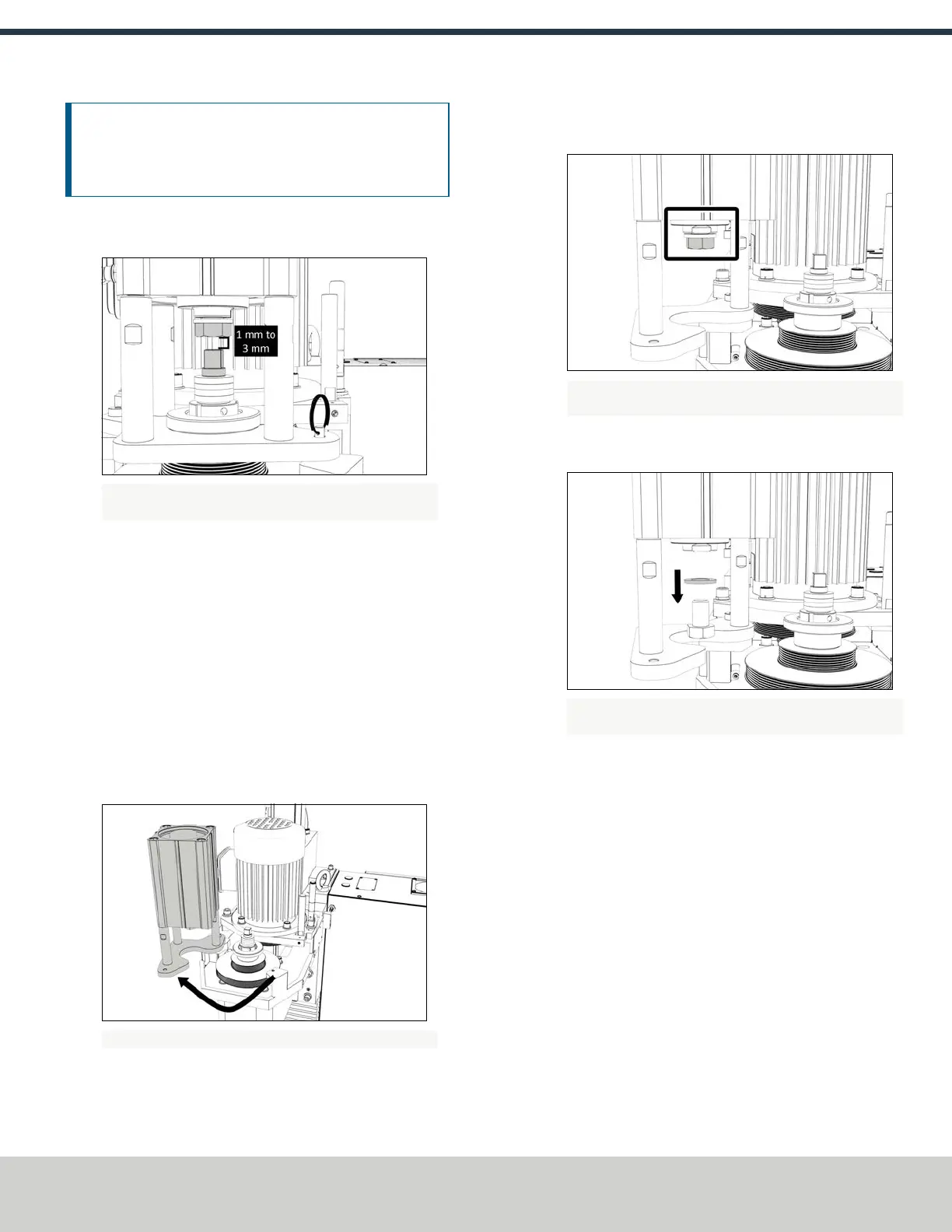

Figure 2-25: Hex head screw on the Power Drawbar

cylinder's rod.

7. Remove the M16 washer from the Power Drawbar cylinder’s

rod, and set it aside.

Figure 2-26: M16 washer removed from the Power Drawbar

cylinder's rod.

8. Use an adjustable wrench to reinstall the hex head screw,

and then tighten it completely.

9. Pivot the Power Drawbar cylinder to the original location.

10. Push in the quick-release pin.

11. Reconnect the shop's air supply to the Power Drawbar

button.

12. Examine the space between the hex head screw on the

Power Drawbar cylinder’s rod and the top of the drawbar.

13. Makesure that the gap is between 1 mm and 3 mm.

Depending on the size of the gap, do one of the following:

l If the gap is between 1 mm and 3 mm, go to "Operating

the Power Drawbar" (page12).

l If the gap is less than 1 mm, go to Step 14.

14. Identify the three extra M16 flat washers provided.

©Tormach® 2018

Specifications subject to change without notice.

Page 10 tormach.com

TD10541: Owner's Guide: 770M® Power Drawbar (0618A)

TECHNICAL DOCUMENT

Loading...

Loading...