5. Move one spring washer on the drawbar, with the convex

side of the spring washer toward the drawbar head.

Figure 2-5: Example of moving the convex side of a spring

washer toward the drawbar head.

6. Move another spring washer on the drawbar, with the

concave side of the spring washer toward the concave side

of the spring washer from Step 5.

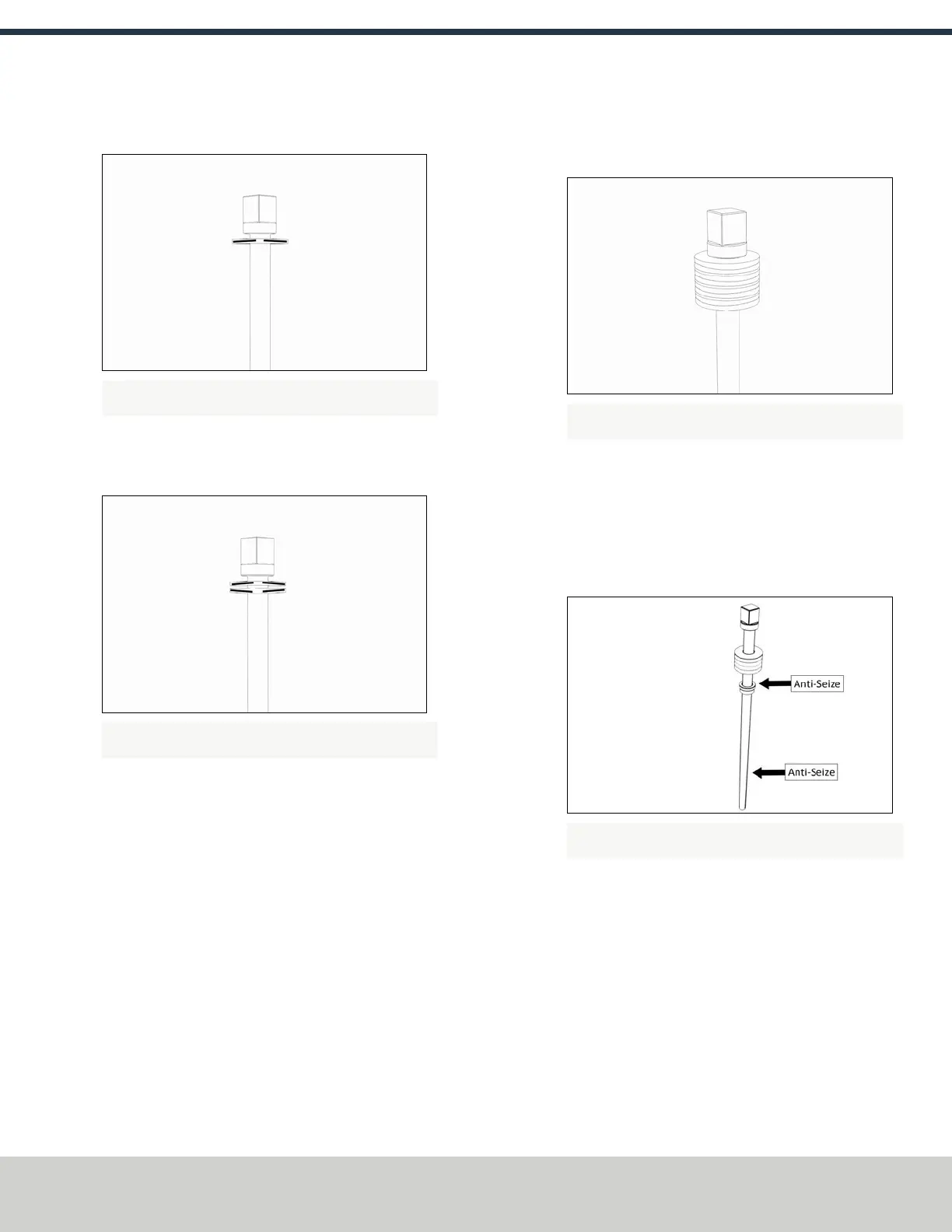

Figure 2-6: Example of moving the concave sides of two

spring washers together.

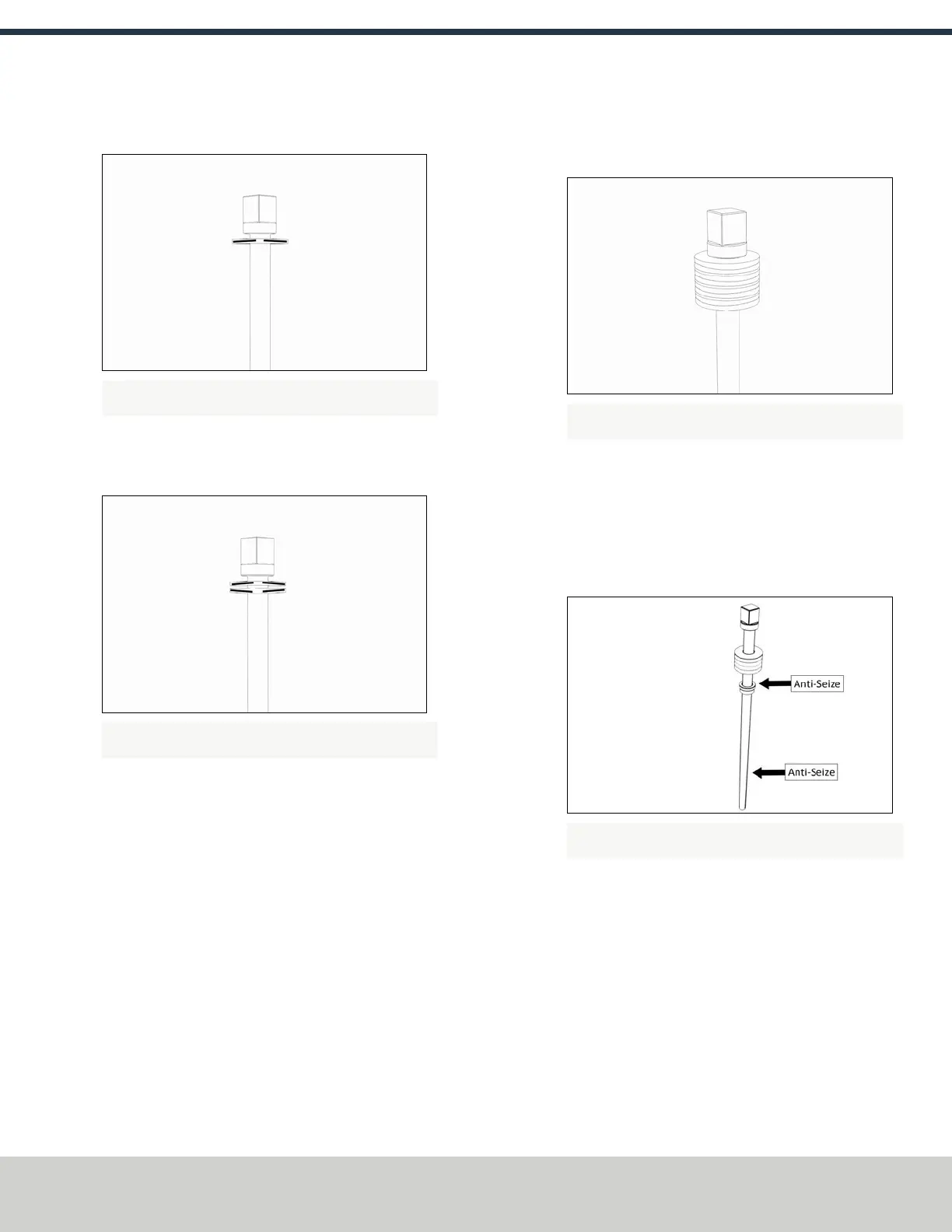

7. Put Anti-Seize on the edge of the contact surface between

the pair of spring washers that you put on the drawbar in

Step 5 and Step 6.

8. Repeat steps 5-7 for the remaining six spring washers. Make

sure that you put Anti-Seize on the spring washers at every

contact point.

9. Examine the stack of spring washers. Make sure that all

eight spring washers are installed on the drawbar and

arranged in four sets of opposing pairs.

Figure 2-7: Example of all eight spring washers installed on

the drawbar.

10. Identify the drawbar bushing that you set aside in Step 2,

and reinstall it on the drawbar. Make sure that the smaller

diameter of the drawbar bushing is toward the bottom of

the drawbar.

11. Put Anti-Seize on the top of the drawbar bushing.

12. Put Anti-Seize on the bottom threads of the drawbar.

Figure 2-8: Example of the locations to apply Anti-Seize on a

drawbar assembly.

13. Put Anti-Seize on the outside taper of the Tormach Tooling

System® (TTS®) collet. Make sure that there is no Anti-Seize

on the inside of the collet.

14. Insert the drawbar assembly into the spindle.

©Tormach® 2018

Specifications subject to change without notice.

Page 5 tormach.com

TD10541: Owner's Guide: 770M® Power Drawbar (0618A)

TECHNICAL DOCUMENT

Loading...

Loading...