8through10untiltheoillevelonthedipstick

iscorrect.

•Iftheoillevelonthedipstickistoohigh,

draintheexcessoiluntiltheoillevelonthe

dipstickiscorrect.

Important:Iftheoillevelintheengineistoo

lowortoohighandyouruntheengine,you

maydamagetheengine.

11.Installthedipstickintotheoil-lltubesecurely.

12.Recycletheusedoilproperly.

ReplacingtheBlade

ServiceInterval:Yearly

Important:Youwillneedatorquewrenchto

installthebladeproperly.Ifyoudonothavea

torquewrenchorareuncomfortableperforming

thisprocedure,contactanAuthorizedService

Dealer.

Examinethebladewheneveryourunoutoffuel.Ifthe

bladeisdamagedorcracked,replaceitimmediately.

Ifthebladeedgeisdullornicked,haveitsharpened

andbalanced,orreplaceit.

WARNING

Thebladeissharp;contactingthebladecan

resultinseriouspersonalinjury.

Weargloveswhenservicingtheblade.

1.RefertoPreparingforMaintenance(page19).

2.Tipthemachineontoitssidewiththeairlterup.

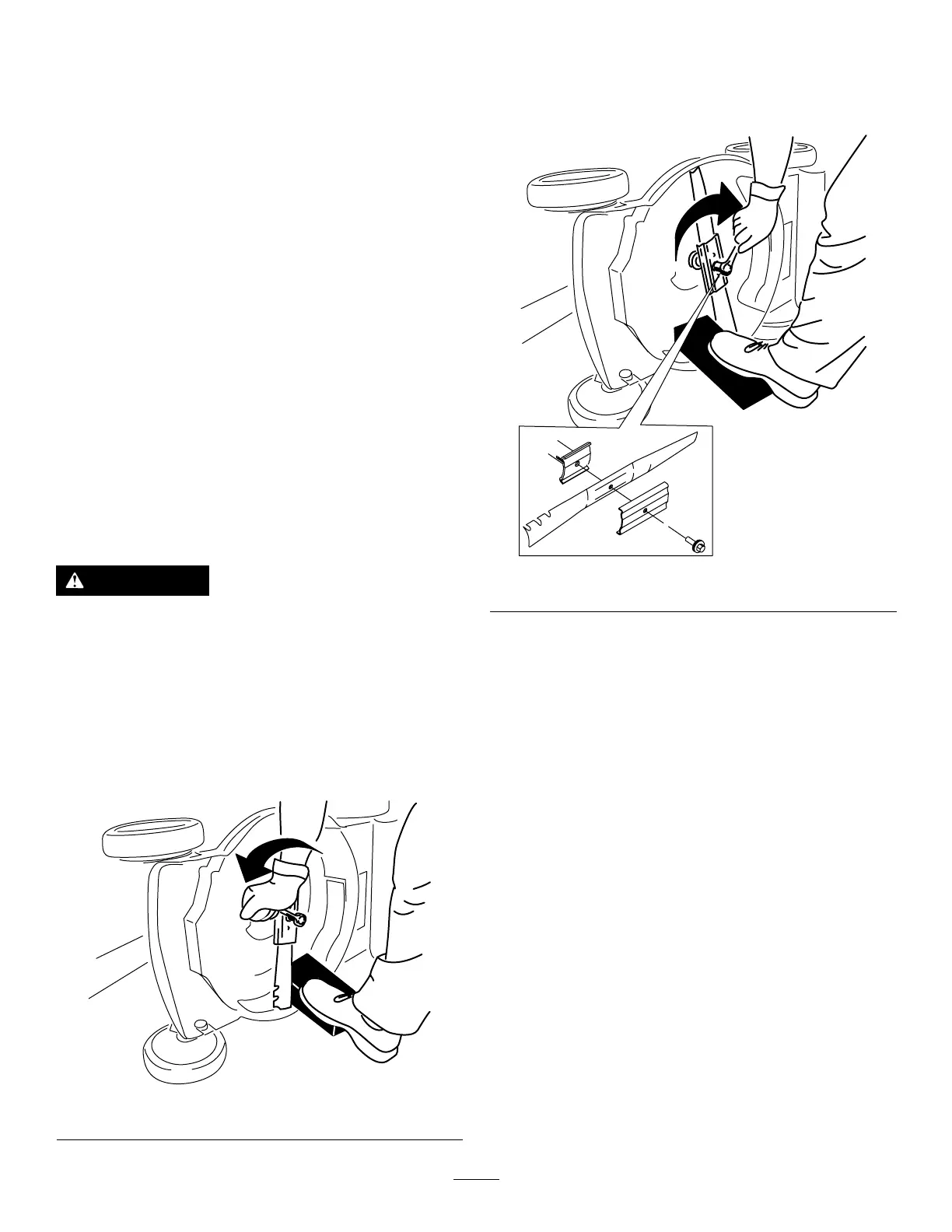

3.Useablockofwoodtoholdthebladesteady

(Figure28).

g231389

Figure28

4.Removetheblade,savingallmountinghardware

(Figure28).

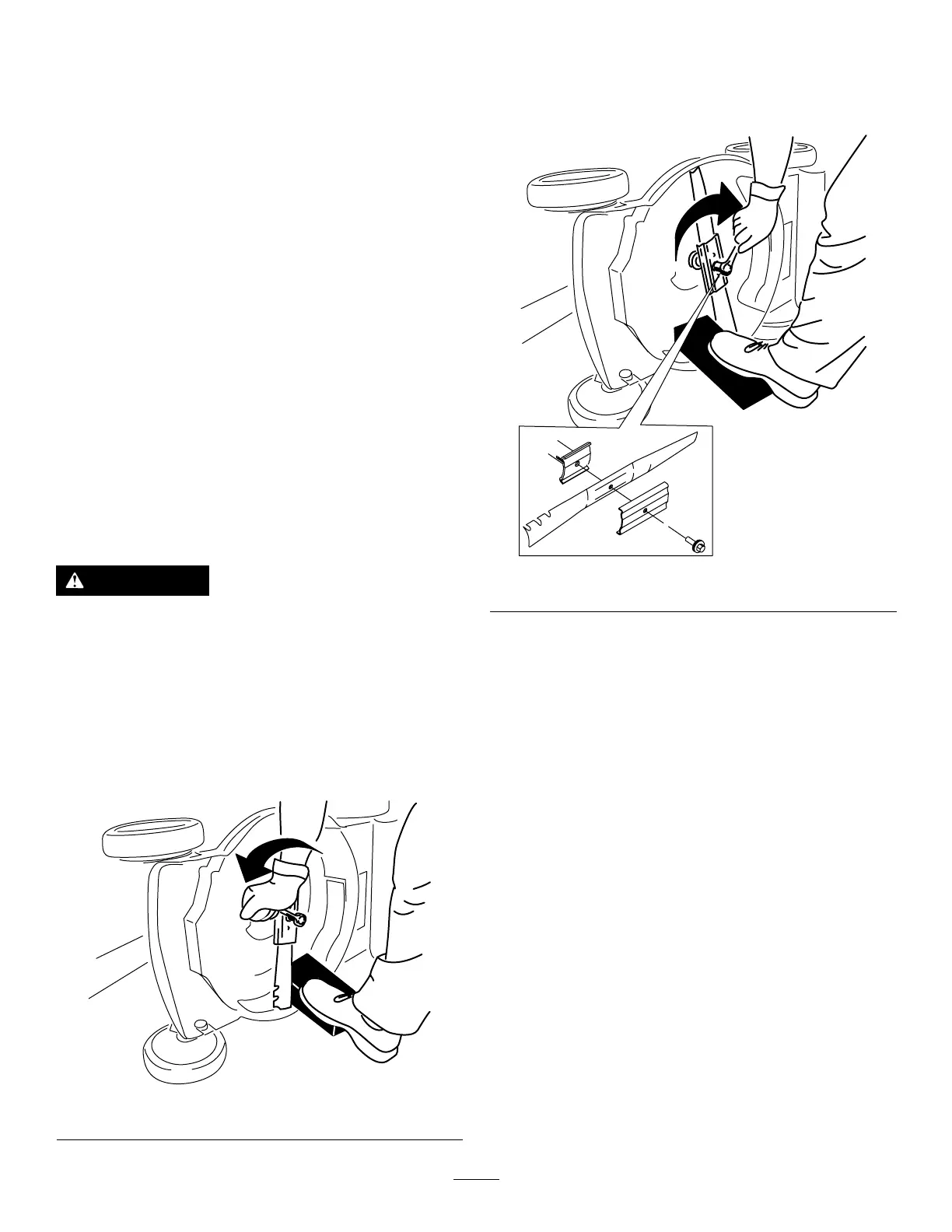

5.Installthenewbladeandallmountinghardware

(Figure29).

g231390

Figure29

Important:Positionthecurvedendsofthe

bladetopointtowardthemachinehousing.

6.Useatorquewrenchtotightenthebladebolt

to82N∙m(60ft-lb).

Important:Abolttorquedto82N∙m(60

ft-lb)isverytight.Whileholdingtheblade

withablockofwood,putyourweight

behindtheratchetorwrenchandtightenthe

boltsecurely.Thisboltisverydifcultto

overtighten.

21

Loading...

Loading...