Replacing the Tracks (Model 22319)

W hen the trac ks are badly w or n, re place them.

1. Lo w er the loader ar ms , stop the engine , and

remo v e the k ey .

2. Lift/suppor t the side of the unit to be w ork ed

on so that the trac k is 3 to 4 inc hes (7.6 to 10

cm) off of the g round.

3. R emo v e the loc king bolt and n ut ( Figure 45 ).

4. Using a 1/2 inc h dri v e soc k et, release the

dri v e tension b y tur ning the tensioning screw

cloc kwise ( Figure 45 and Figure 46 ).

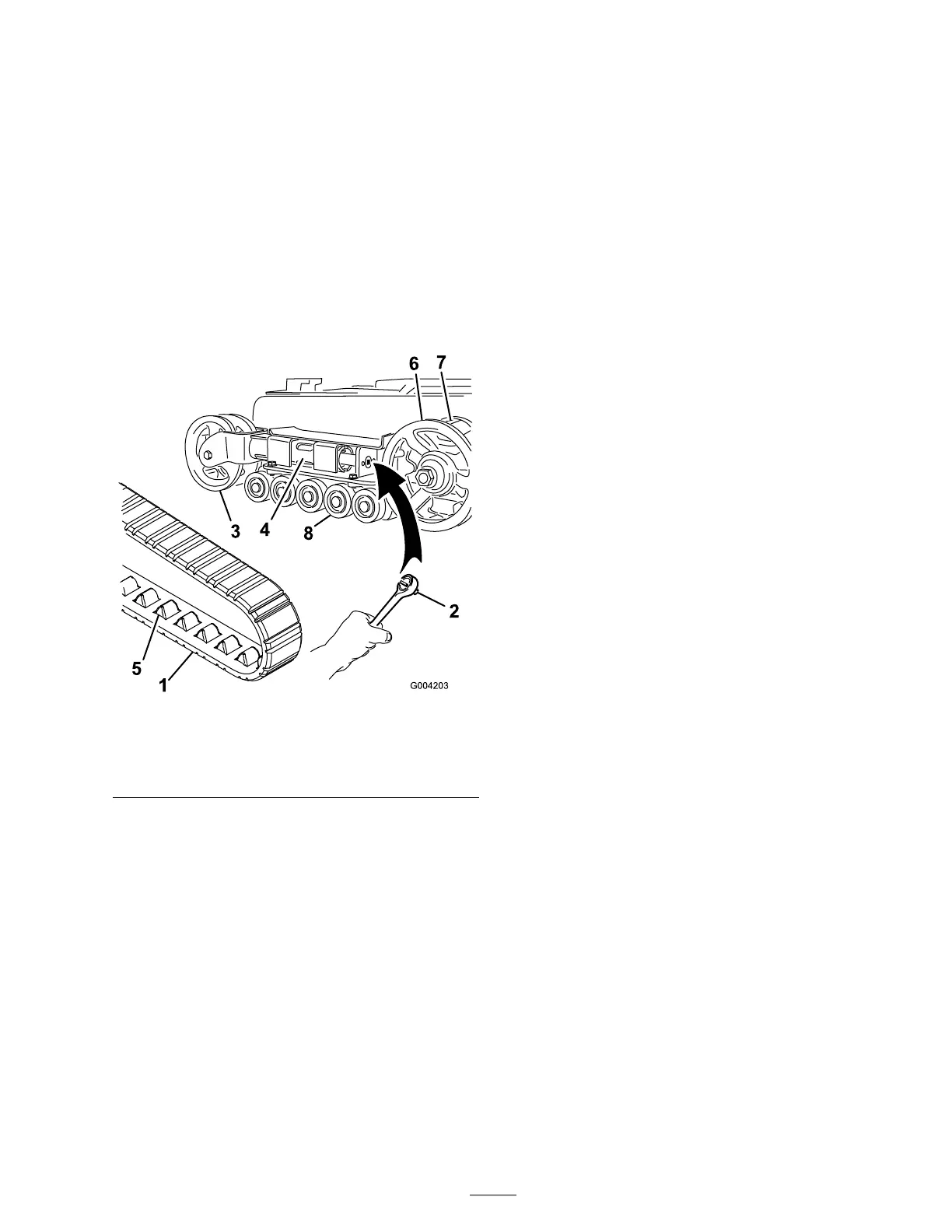

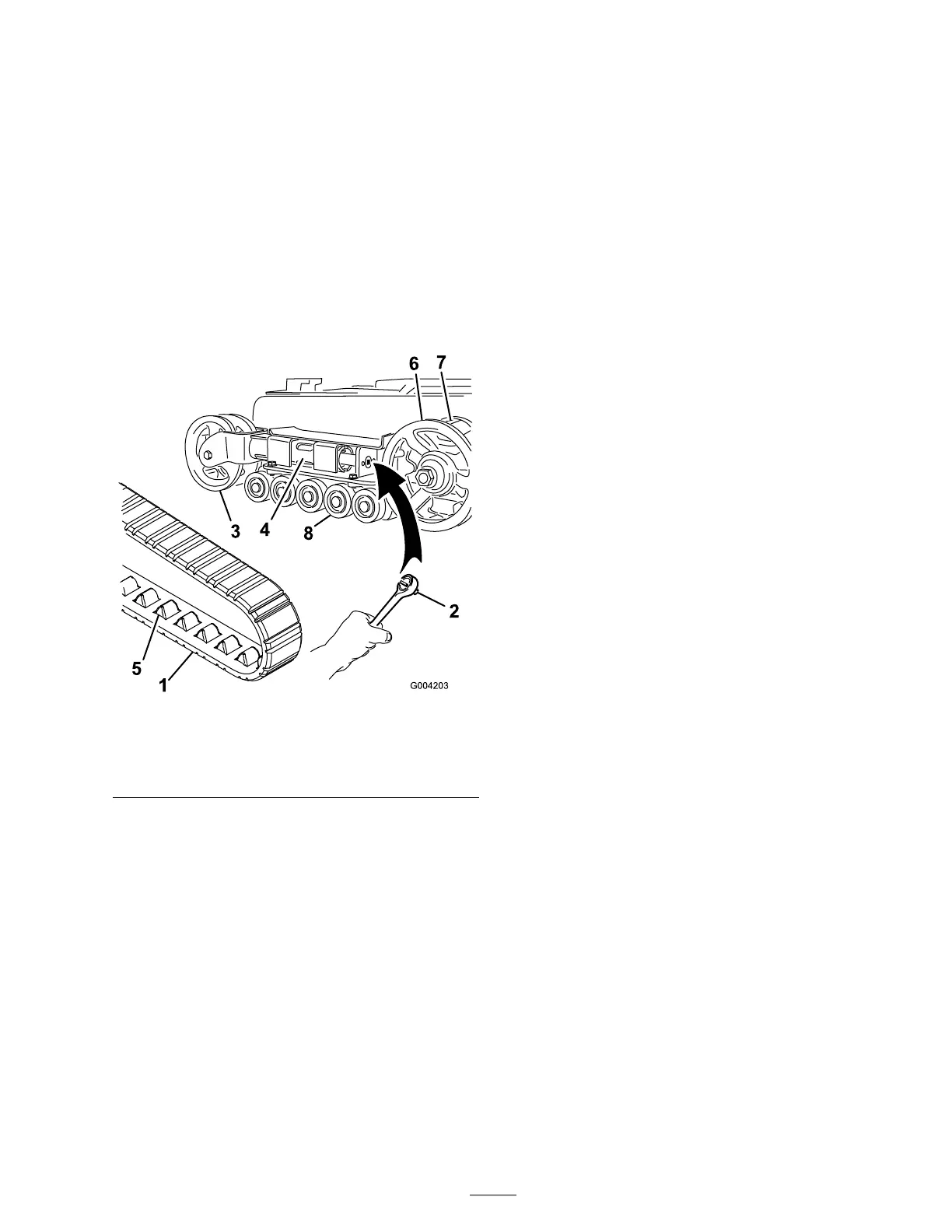

Figure 46

1. Track 5. Track lug

2. 1/2 inch socket 6. Drive sprocket

3. Tension wheel 7. Sprocket spacer

4. Fork tube 8. Road wheels

5. Push the tension wheel to w ard the rear of the

unit to mo v e the fork tube ag ainst the frame

( Figure 46 ). (If it does not touc h the frame ,

contin ue tur ning the tensioning screw until it

does .)

6. Begin remo ving the trac k at the top of the

tension wheel, peeling it off of the wheel while

rotating the trac k forw ards .

7. W hen the trac k is off of the tension wheel,

remo v e it from the dri v e sproc k et and road

wheels ( Figure 46 ).

8. Beginning at the dri v e sproc k et, coil the new

trac k around the sproc k et, ensuring that the

lugs on the trac k fit betw een the spacers on the

sproc k et ( Figure 46 ).

9. Push the trac k under and betw een the road

wheels ( Figure 46 ).

10. Star ting at the bottom of the tension wheel,

install the trac k around the wheel b y rotating

the trac k rearw ard while pushing the lugs into

the wheel.

11. T ur n the tensioning screw counter -cloc kwise

until the distance betw een the tension n ut and

the bac k of the fork tube ( Figure 44 ) is 2-3/4

inc hes (7 cm).

12. Align the closest notc h in the tension screw to

the loc king bolt hole and secure the screw with

the loc king bolt and n ut.

13. Lo w er the traction unit to the g round.

14. R e peat ste ps 2 through 13 to re place the other

trac k.

Replacing the Tracks (Model 22320)

W hen the trac ks are badly w or n, re place them.

1. Lo w er the loader ar ms , stop the engine , and

remo v e the k ey .

2. Lift/suppor t the side of the unit to be w ork ed

on so that the trac k is 3 to 4 inc hes (7.6 to 10

cm) off of the g round.

3. R emo v e the loc king bolt and n ut ( Figure 45 ).

4. Using a 1/2 inc h dri v e soc k et, release the

dri v e tension b y tur ning the tensioning screw

cloc kwise ( Figure 45 and Figure 47 ).

39

Loading...

Loading...