SCAMP

BRAKE

SERVICING AND REPAIR

Pull bail back against the handle to release the

brake.

Lift flywheel off.

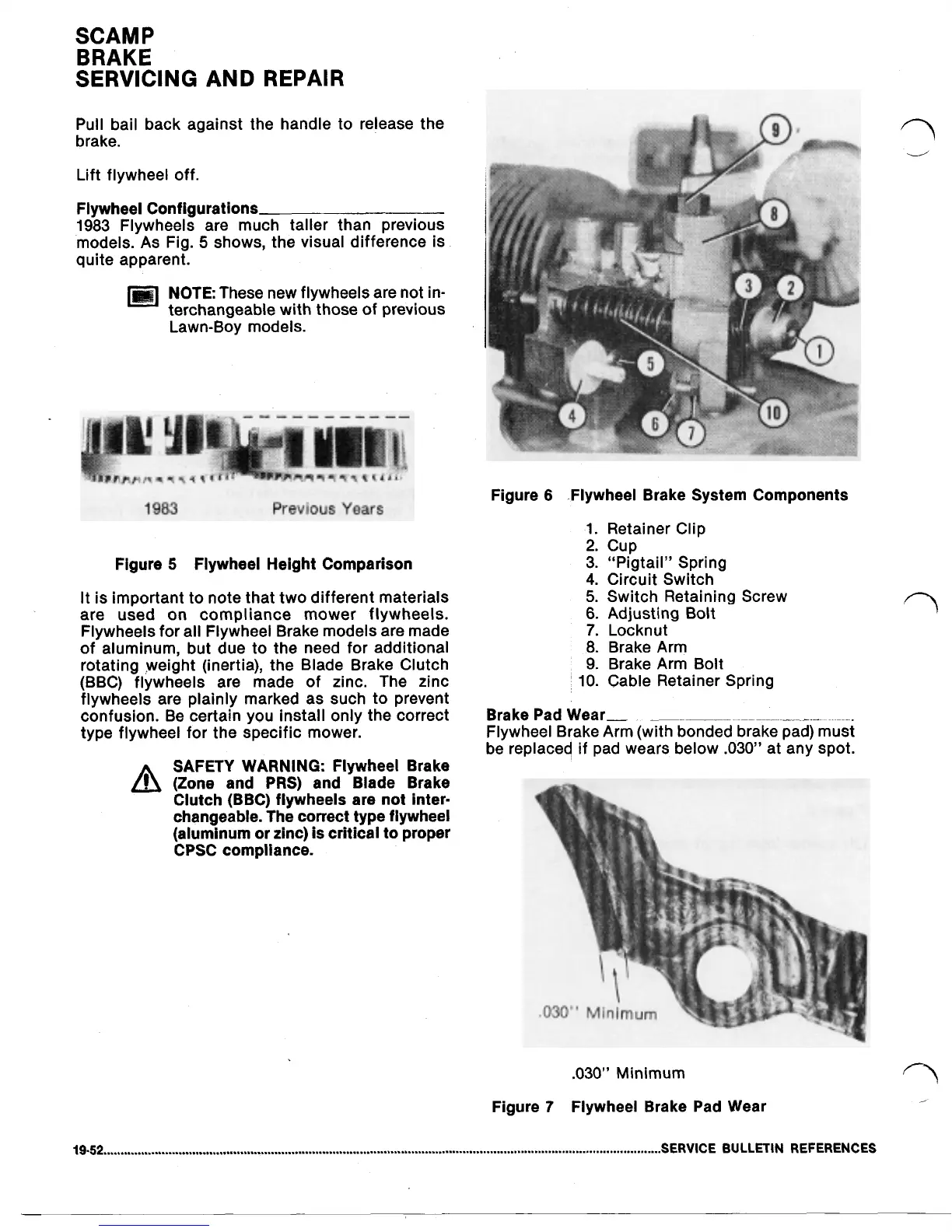

Flywheel Configurations

1983 Flywheels are much taller than previous

models. As Fig.

5

shows, the visual difference is

quite apparent.

NOTE

These new flywheels are not in-

terchangeable with those of previous

Lawn-Boy models.

1983

Previous Years

Figure

5

Flywheel Height Comparison

It is important to note that two different materials

are used

on

compliance mower flywheels.

Flywheels for all Flywheel Brake models are made

of aluminum, but due

to

the need for additional

rotating weight (inertia), the Blade Brake Clutch

(BBC) flywheels are made of zinc. The zinc

flywheels are plainly marked as such to prevent

confusion. Be certain you install only the correct

type flywheel for the specific mower.

SAFETY WARNING: Flywheel Brake

(Zone and PRS) and Blade Brake

Clutch (BBC) flywheels are not inter-

changeable. The correct type flywheel

(aluminum or zinc) is critical to proper

CPSC compliance.

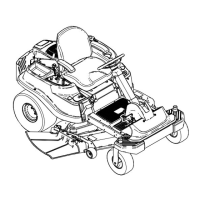

Figure

6

.Flywheel Brake System Components

1. Retainer Clip

2.

cup

3. “Pigtail” Spring

4.

Circuit Switch

5.

Switch Retaining Screw

6.

Adjusting Bolt

7.

Locknut

8. Brake Arm

9.

Brake Arm Bolt

10. Cable Retainer Spring

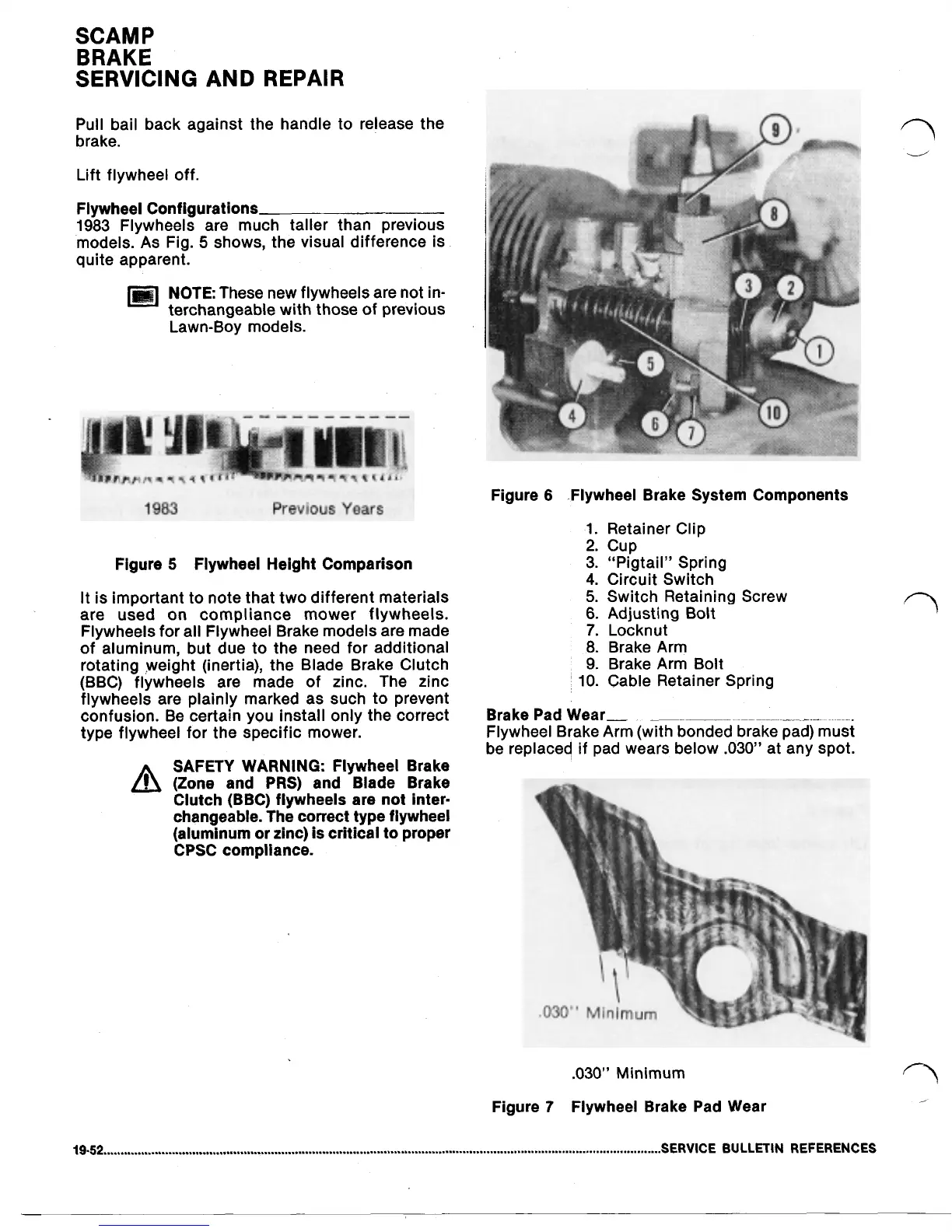

Brake Pad Wear-

Flywheel Brake Arm (with bonded brake pad) must

be replaced

if

pad wears below .030” at any spot.

.030”

Minimum

Figure

7

Flywheel Brake Pad Wear

19-52

SERVICE

BULLETIN

REFERENCES

Loading...

Loading...