SCAMP

BRAKE

SERVICING AND REPAIR

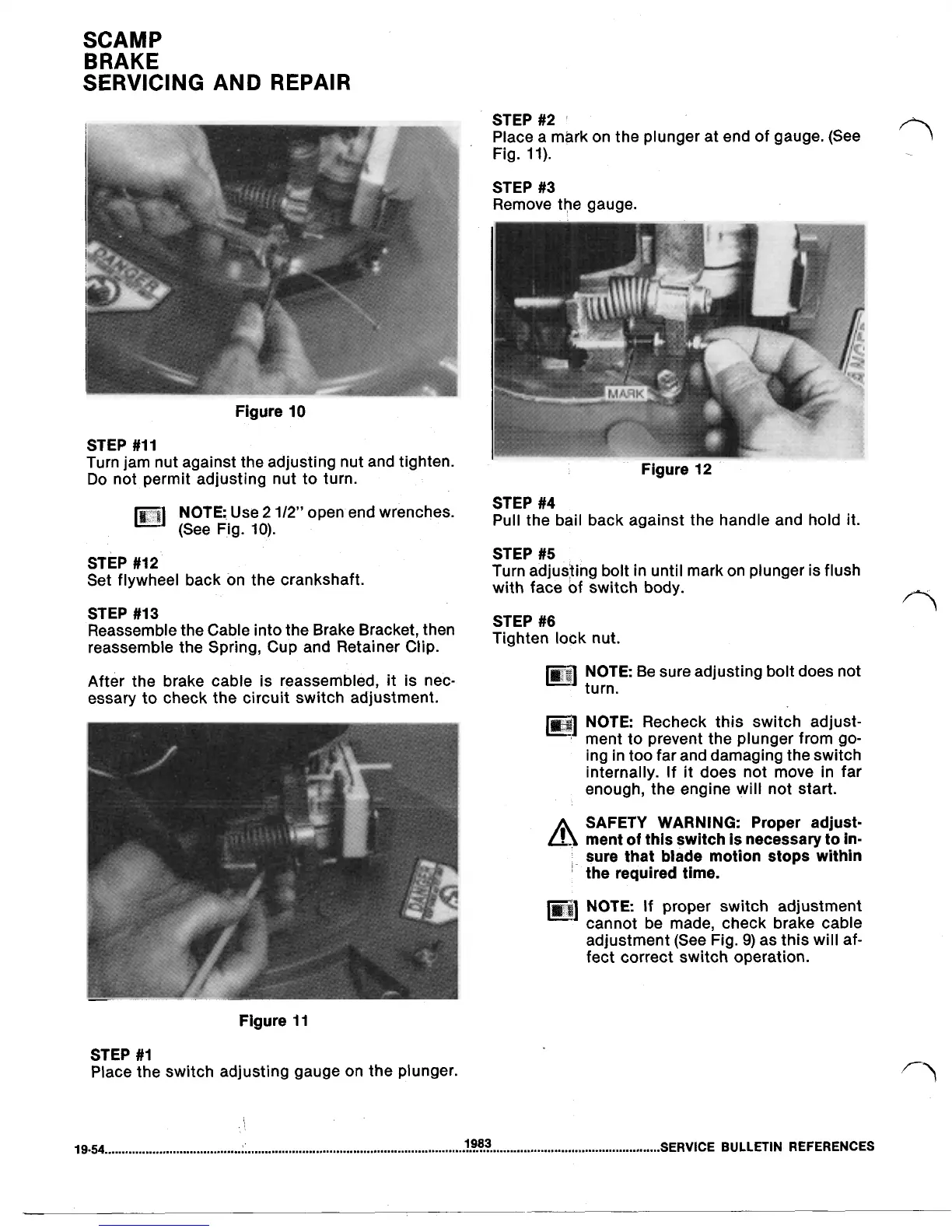

STEP

#2

Place a mark on the plunger at end of gauge. (See

Fig.

11).

STEP

#3

Remove the gauge.

Figure

10

STEP

#11

Turn jam nut against the adjusting nut and tighten.

Do

not permit adjusting nut to turn.

Figure

12

STEP

#4

(See Fig.

10).

Use

1/2”

Open

end

wrenches.

Pull the bail back against the handle and hold

it.

STEP

#12

Set flywheel back on the crankshaft.

STEP

#5

Turn adjusting bolt in until mark on plunger is flush

with face of switch body.

STEP

#13

Reassemble the Cable into the Brake Bracket, then

Tighten

nut.

reassemble the Spring, Cup and Retainer Clip.

STEP

#6

After the brake cable is reassembled,

it

is nec-

essary to check the circuit switch adjustment.

NOTE

Be sure adjusting bolt does not

turn.

NOTE

Recheck this switch adjust-

ment to prevent the plunger from go-

ing in too far and damaging the switch

internally.

If

it does not move in far

enough, the engine will not start.

SAFETY WARNING: Proper adjust-

ment

of

this switch is necessary

to

in-

sure that blade motion stops within

the required time.

NOTE

If

proper switch adjustment

cannot be made, check brake cable

adjustment (See Fig.

9)

as this will af-

fect correct switch operation.

Figure

11

STEP

#1

Place the switch adjusting gauge on the plunger.

19.54

SERVICE BULLETIN REFERENCES

1983

Loading...

Loading...