41

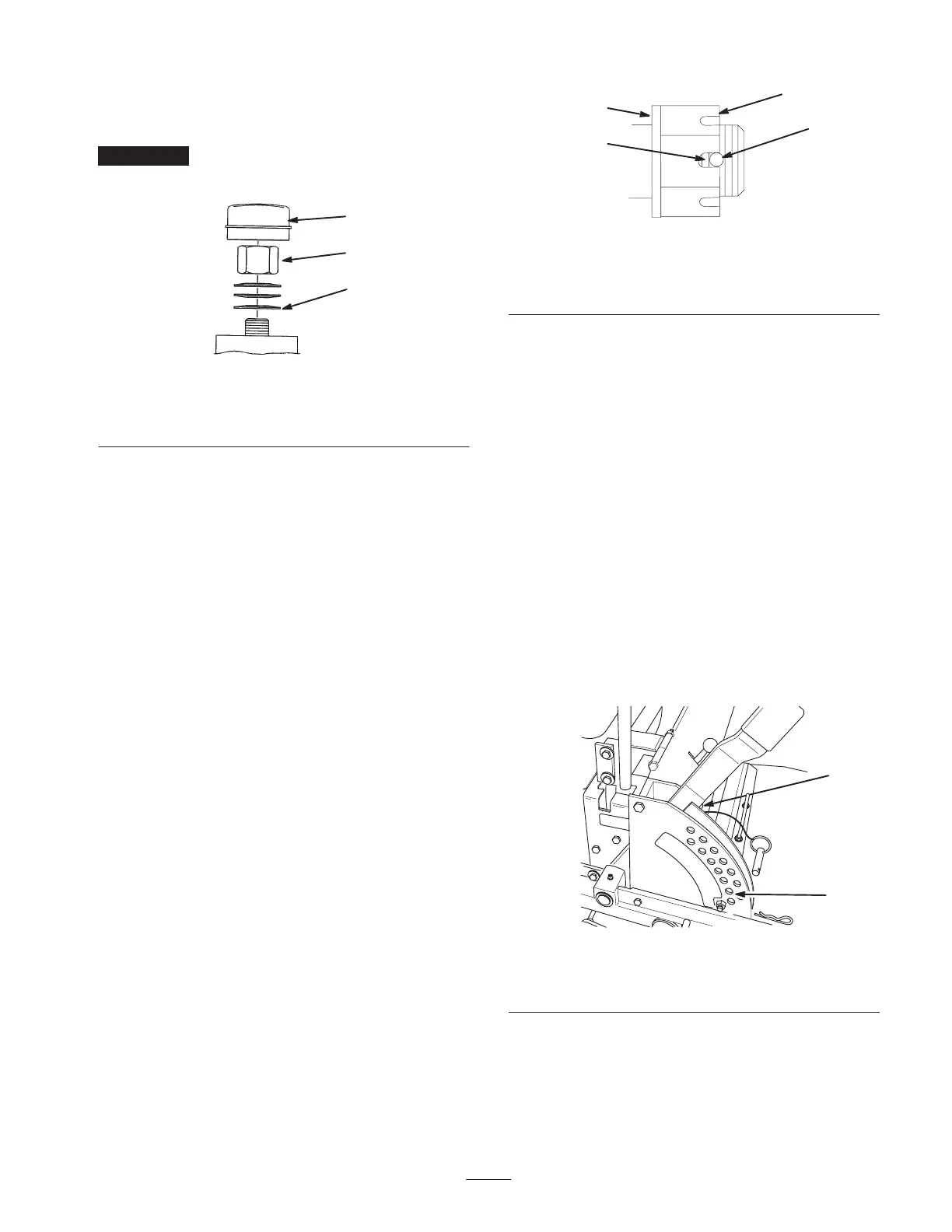

3. Tighten until the spring washers are flat and then back

off 1/4 turn to properly set the preload on the bearings

(Fig. 53).

Important Make sure that the spring washers are

installed correctly as shown in Figure 53.

1

M–4640

2

3

Figure 53

1. Spring washers

2. Locknut

3. Dust cap

Checking the Wheel Hub

Slotted Nut

Check after every 500 operating hours.

The slotted nut needs to be torqued to 125 ft.-lb. (170 N⋅m).

1. Stop the engine, set the parking brake, remove the key,

and disconnect the spark plug wire(s) from the spark

plug(s).

2. Remove the cotter pin.

3. Torque the slotted nut to 125 ft.-lb. (170 N⋅m) (Fig. 54).

4. Check the distance from the bottom of the slot in the

nut to the inside edge of the hole. Two threads or less

should be showing (Fig. 54).

5. If more than two threads are showing, remove the nut

and install a washer between the hub and nut (Fig. 54).

6. Torque the slotted nut to 125 ft.-lb. (170 N⋅m) (Fig. 54).

7. Tighten the nut until the next set of slots line up with

the hole in the shaft (Fig. 54).

8. Install the cotter pin.

3

m–4638

1

2

4

Figure 54

1. Slotted nut

2. Two threads or less

showing

3. Hole in threaded rod

4. Washer (if needed)

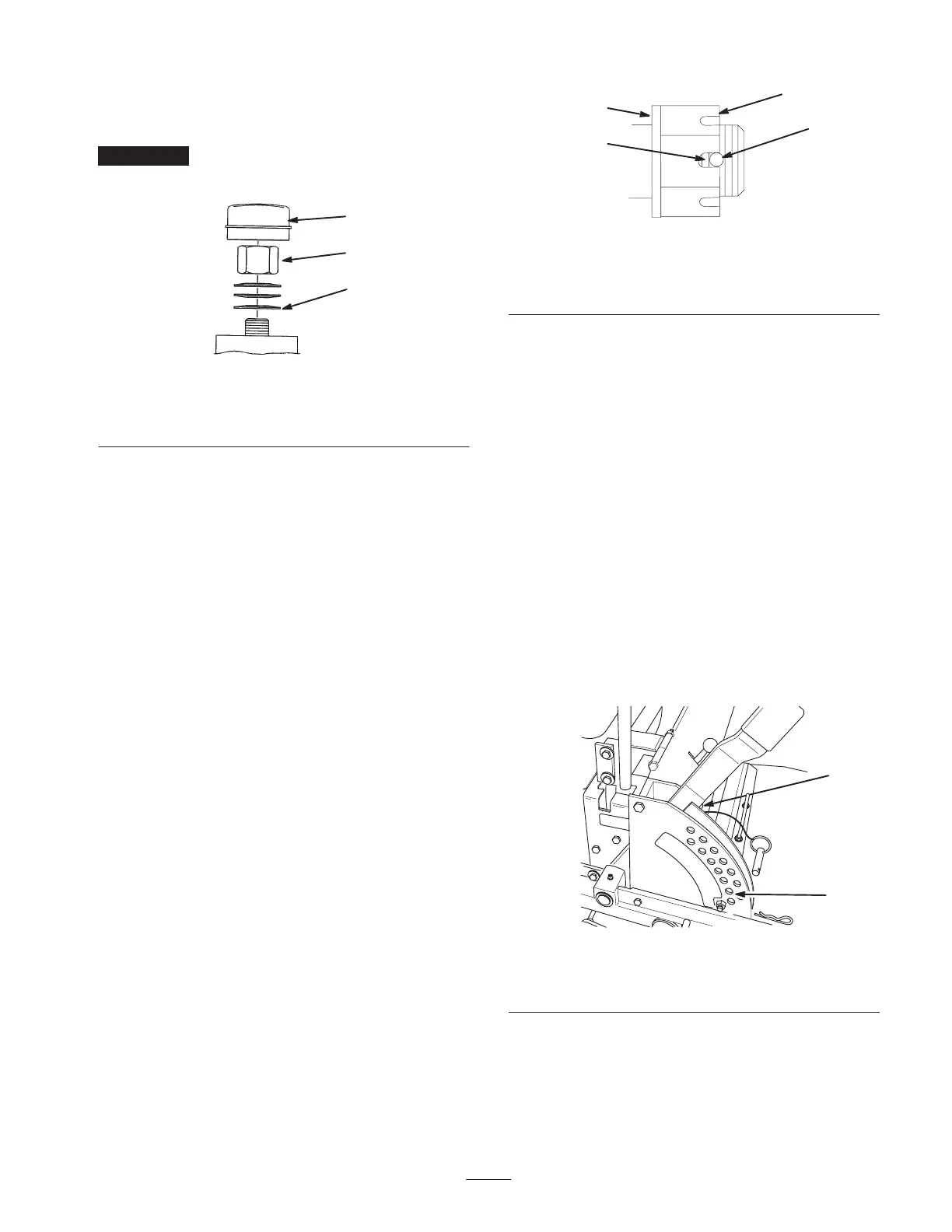

Adjusting the Mower Level

1. Position the mower on a flat surface. Stop the engine,

set the parking brake, remove the key, and disconnect

the spark plug wire(s) from the spark plug(s).

2. Check the tire pressure of all 4 tires. If needed, adjust to

13 psi (90 kPa).

3. Set the anti-scalp rollers to the top holes or remove

them completely for this adjustment.

4. Raise the deck to the transport position and take all of

the force off of the two large deck lift springs by

loosening the nut in front of each spring (Fig. 55).

5. Place 2 thick blocks (1-1/2 in. [38 mm]) under the rear

left and right lower edge of the mower. Place 1 block

(2-1/4 in. [57 mm]) under the front center lower edge of

the mower. Lower the mower to the 2 in. (51 mm)

height-of-cut position (Fig. 55).

m–4164

1

2

Figure 55

1. Transport position

2. 2 in. (51 mm) height-of-cut

Loading...

Loading...