Maintenance

56

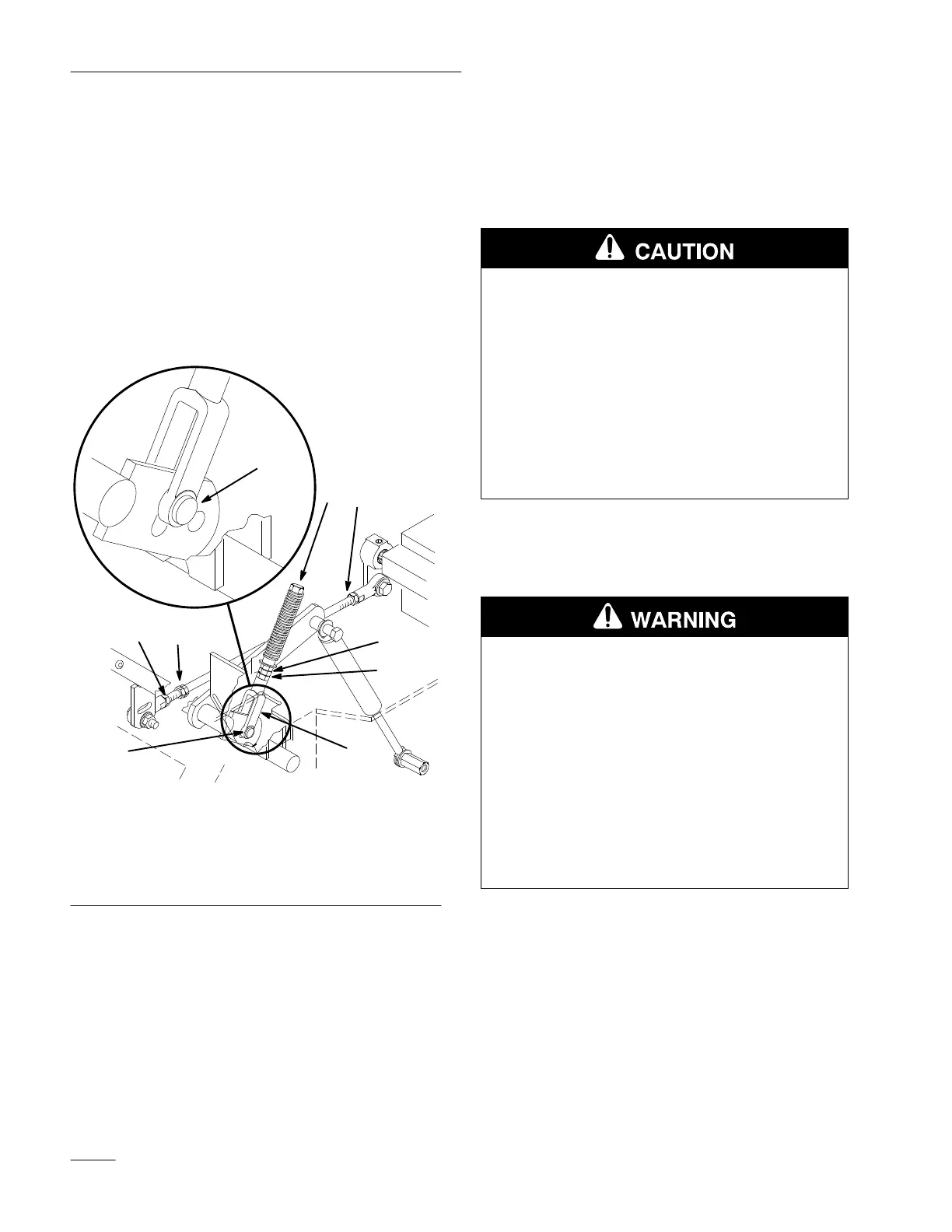

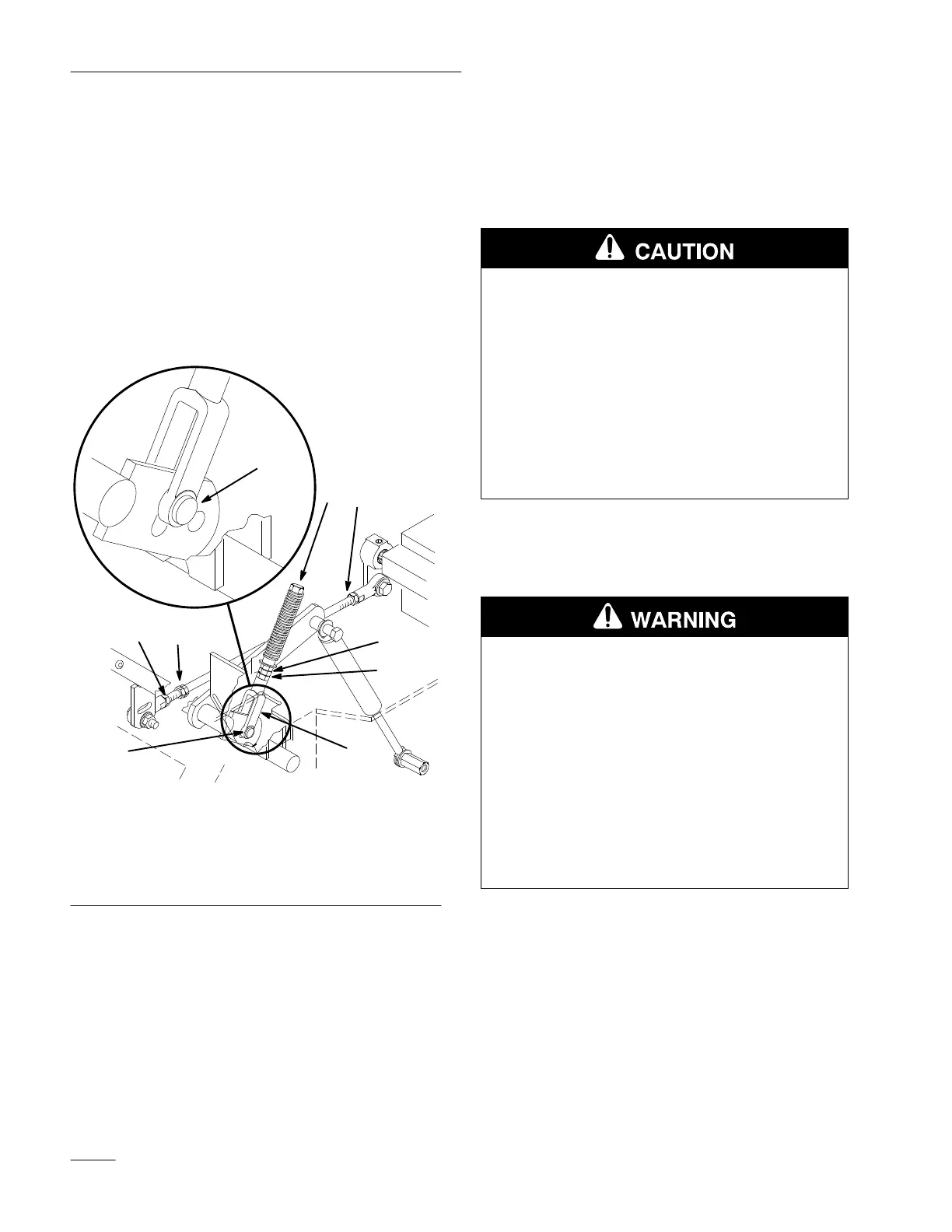

5. Apply slight rearward pressure on the motion

control lever, turn the head of the adjustment

bolt in the appropriate direction until lever is

centered in neutral lock position (keeping

rearward pressure on the lever will keep the pin

at the end of the slot and allow the adjustment

bolt to move the lever to the appropriate position

(Fig. 50).

6. Tighten nut and jam nut.

7. Repeat on opposite side of unit.

1

1

2

6

4 3

2

7

8

Figure 50

1. Clevis

pin in slot

2. Nut

3.

Nut– Left hand Thread

4. Bolt

5.

Pump rod

6.

Double nuts

7.

Jam Nut

8. Yoke

Adjusting Hydraulic Pump Neutral

Note: Adjust handle neutral first. That has to

be correct before the following

adjustment can be made.

POTENTIAL HAZARD

• Mechanical or hydraulic jacks may not

support machine.

WHAT CAN HAPPEN

• Weight of machine can cause hydraulic

jacks to fail and cause an injury.

HOW TO AV

OID THE HAZARD

• Use jack stands when supporting machine.

• Do not use hydraulic jacks.

1. This adjustment must be made with drive wheels

turning. First raise the frame and block up so

drive wheels can rotate freely.

POTENTIAL HAZARD

• Engine must be running so motion control

adjustment can be performed.

WHAT CAN HAPPEN

• Contact with moving parts or hot surfaces

may cause personal injury.

HOW TO AV

OID THE HAZARD

• Keep hands, feet, face, clothing and other

body parts away from rotating parts,

muffler and other hot surfaces.

2. Slide seat forward, disconnect prop rod and tilt

seat fully forward.

3. Disconnect electrical connector from the seat

safety switch. Temporarily

install a jumper wire

across terminals in the wiring harness connector.

4. Loosen locknut at ball joint on pump control rod

(Fig. 50).

Loading...

Loading...