38

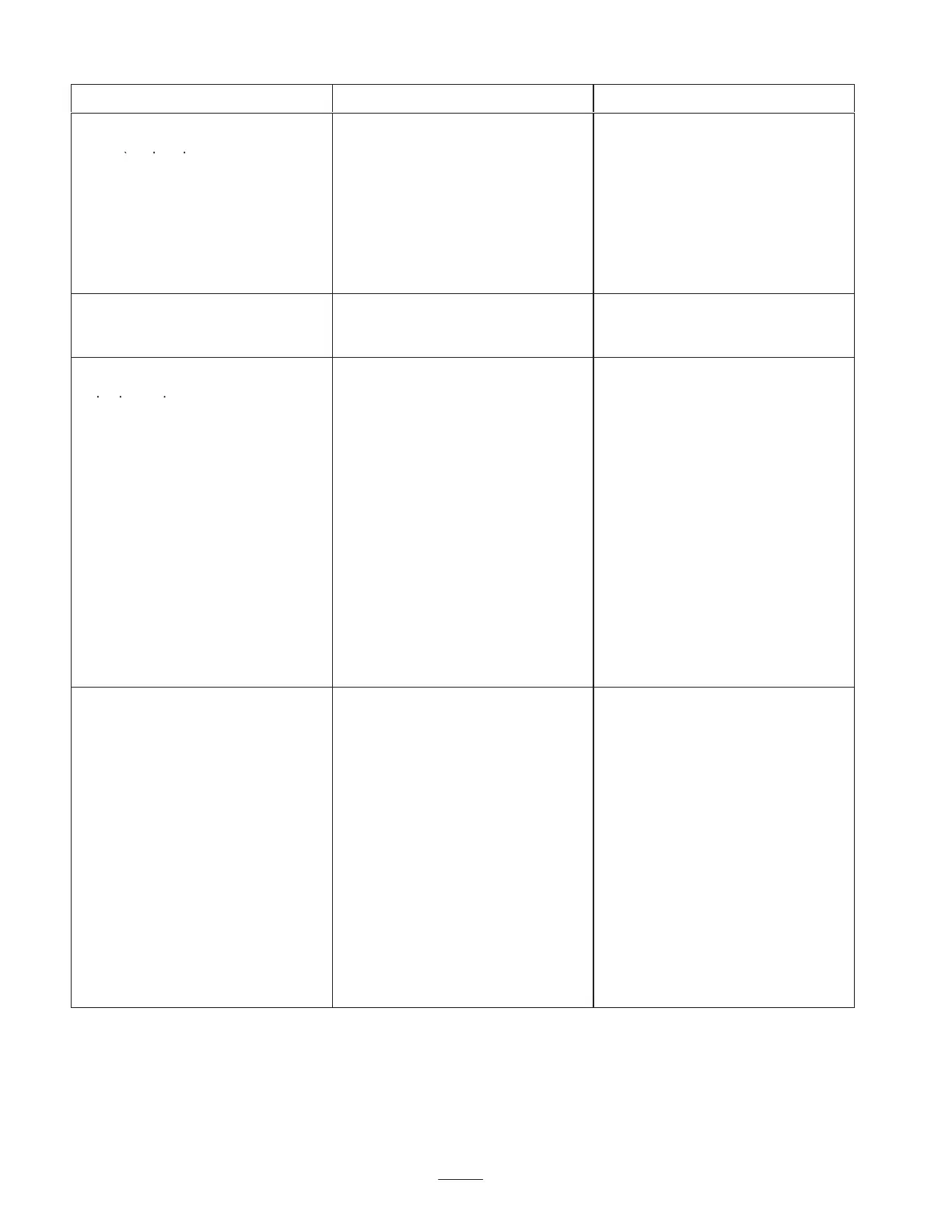

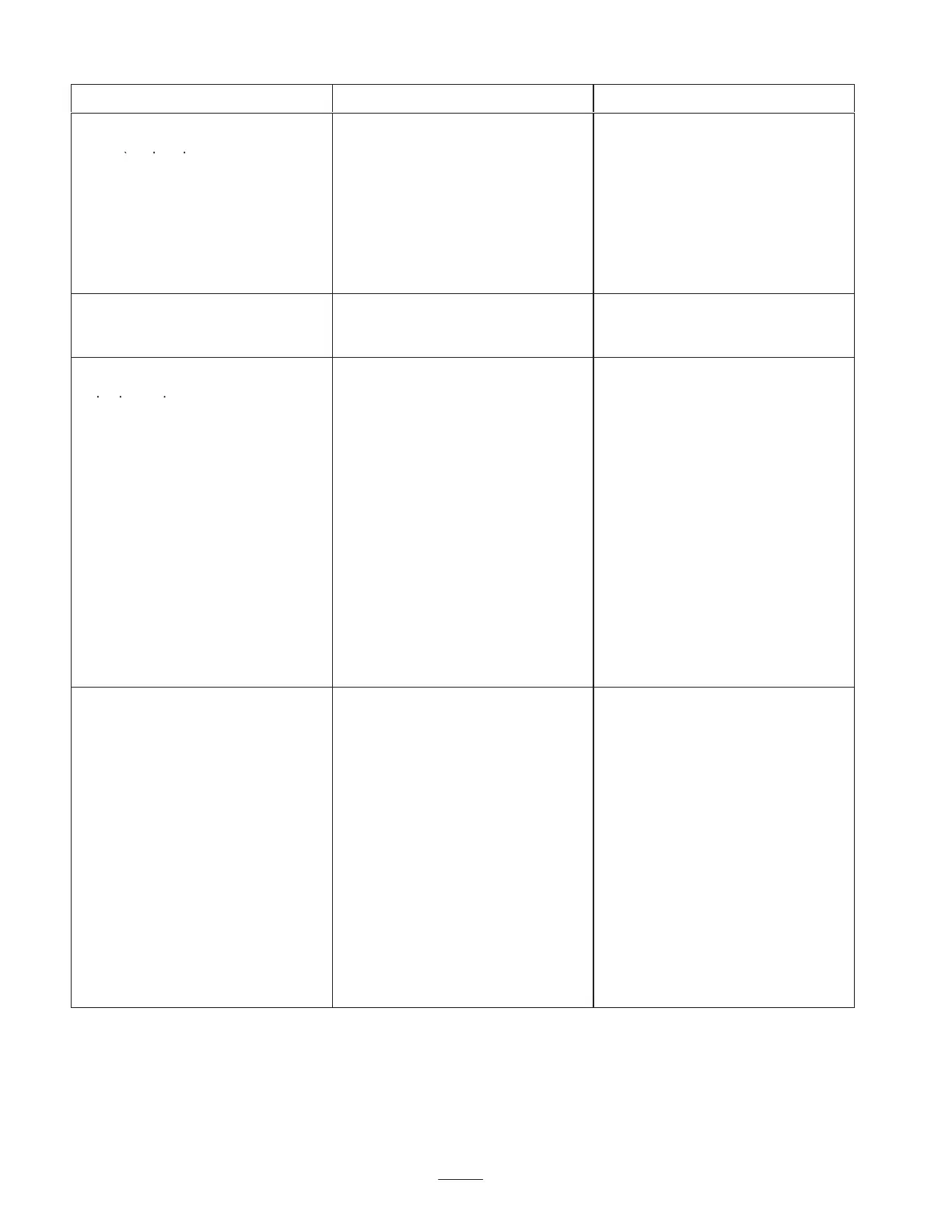

Problem Corrective ActionPossible Causes

The unit is not producing aeration

holes (the pump and valve are

1. There is air in the system. 1. Open the main bleed valve to

purge air from the system.

operating correctly).

2. A nozzle(s) is plugged. 2. Inspect the nozzles.

3. The soil composition is hard. 3. A different nozzle configuration

may be required.

4. Have the water system

checked by an Authorized Toro

Distributor.

The unit is not producing aeration

holes (the injection pump stops

after the unit stops moving).

1. This is a normal condition of

the neutral interlock system.

1. The operator must hold the

Engage (start) button to aerate

without moving.

The holes are shallow or the

improper depth.

1. There is air in the system. 1. Open the main bleed valve to

purge air from the system.

2. If the hole depth was

satisfactory earlier, check the

density and moisture content of

the soil.

2. A different nozzle configuration

may be required.

3. The soil composition is hard. 3. A different nozzle configuration

may be required.

4. There are too many large

nozzles, causing a loss in

pressure which could damage

the accumulator or other water

system components.

4. Open the bleed valve and

examine the nozzles. Verify the

size and quantity per the

recommendation chart.

5. Have the water system

checked by an Authorized Toro

Distributor.

The water injection system is

making an unusual noise when

aerating.

1. There is air in the system. 1. With the water supply on, open

the bleed valve under the

accumulator/valve body. If

mechanical noise continues

during aeration, stop the unit

and have it serviced by an

Authorized Toro Distributor.

2. A nozzle is missing or there are

too many large nozzle installed.

2. Open the bleed valve and

examine the nozzles. Verify the

size and quantity per the

recommendation chart.

3. There are broken springs in the

nozzle extension check valve.

3. Replace the springs and

inspect the ball and seat.

4. The gearbox drive shaft or

couplers are worn.

4. Remove the drive shaft guard

and repair or replace as

necessary.

Loading...

Loading...