|nstaller's Guide

@

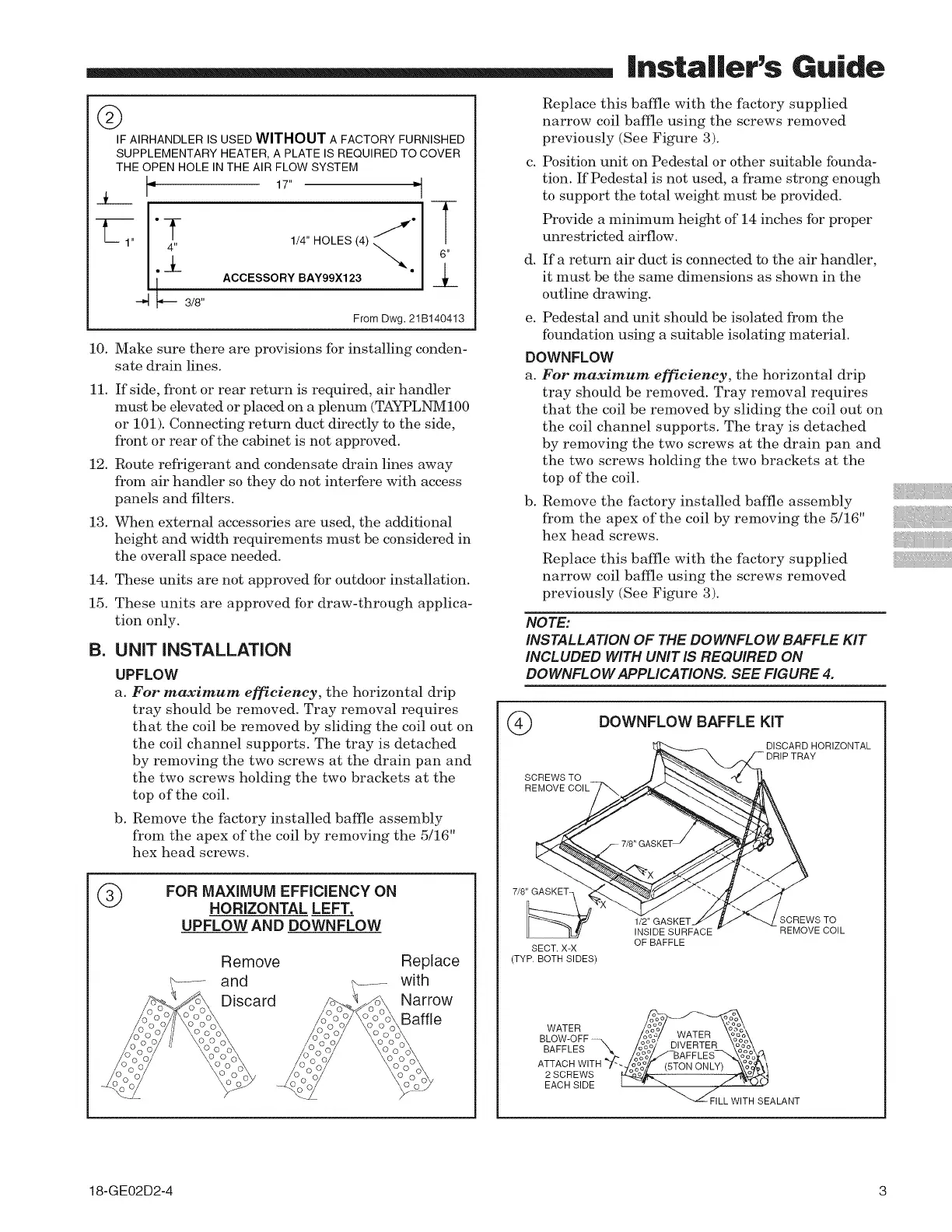

IF AIRHANDLER IS USED WITHOUT A FACTORY FURNISHED

SUPPLEMENTARY HEATER, A PLATE IS REQUIRED TO COVER

THE OPEN HOLE IN THE AIR FLOW SYSTEM

_L I"

I'T .±

_-- 3/8"

17" b]

1/4" HOLES (4) _o

ACCESSORY BAY99X123

From Dwg. 21 B140413

!0. Make sure there are provisions for installing conden-

sate drain lines.

!1. If side, front or rear return is required, air handler

must be elevated or placed on a plenum (TAYPLNM100

or 101). Connecting return duct directly to the side,

front or rear of the cabinet is not approved.

12. Route refrigerant and condensate drain lines away

from air handler so they do not interfere with access

panels and filters.

13. When external accessories are used, the additional

height and width requirements must be considered in

the overall space needed.

14. These units are not approved for outdoor installation.

15. These units are approved for draw-through applica-

tion only.

B. UNIT INSTALLATION

UPFLOW

a. For maximum efficiency, the horizontal drip

tray should be removed. Tray removal requires

that the coil be removed by sliding the coil out on

the coil channel supports. The tray is detached

by removing the two screws at the drain pan and

the two screws holding the two brackets at the

top of the coil.

b. Remove the factory installed baffle assembly

from the apex of the coil by removing the 5/16"

hex head screws.

®

FOR MAXIMUM EFFICIENCY ON

HORIZONTAL LEFT,

UPFLOW AND DOWNFLOW

Remove

and

Discard

Replace

with

Narrow

Baffle

C.

Replace this baffle with the factory supplied

narrow coil baffle using the screws removed

previously (See Figure 3).

Position unit on Pedestal or other suitable founda-

tion. If Pedestal is not used, a frame strong enough

to support the total weight must be provided.

Provide a minimum height of 14 inches for proper

unrestricted airflow.

d. If a return air duct is connected to the air handler,

it must be the same dimensions as shown in the

outline drawing.

e. Pedestal and unit should be isolated from the

foundation using a suitable isolating material.

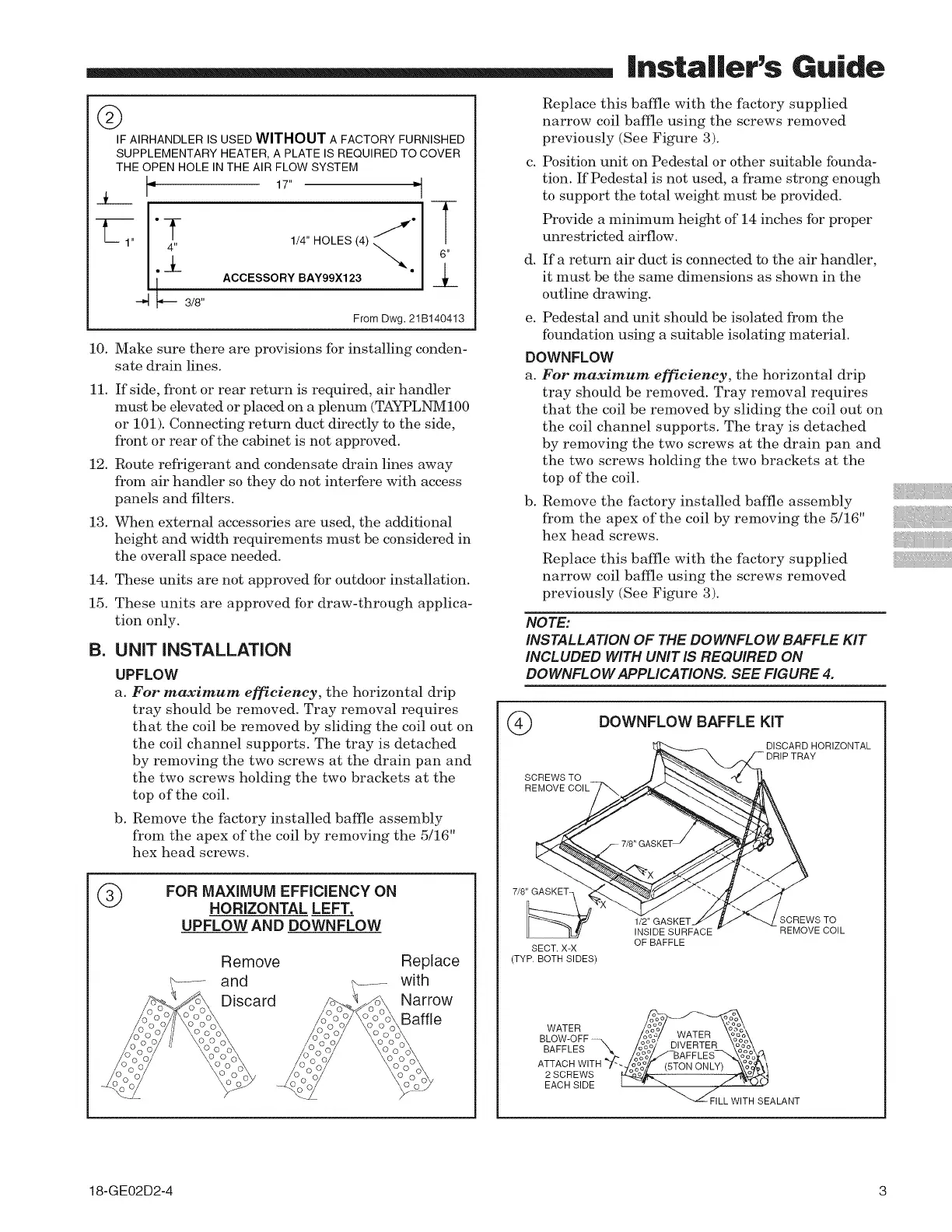

DOWNFLOW

a. For maximum efficiency, the horizontal drip

tray should be removed. Tray removal requires

that the coil be removed by sliding the coil out on

the coil channel supports. The tray is detached

by removing the two screws at the drain pan and

the two screws holding the two brackets at the

top of the coil.

b. Remove the factory installed baffle assembly

from the apex of the coil by removing the 5/16"

hex head screws.

Replace this baffle with the factory supplied

narrow coil baffle using the screws removed

previously (See Figure 3).

NOTE:

INSTALLATION OF THE DOWNFLOW BAFFLE KIT

INCLUDED WITH UNIT IS REQUIRED ON

DOWNFLOW APPLICATIONS. SEE FIGURE 4.

©

SCREWSTO

REMOVE

DOWNFLOW BAFFLE KiT

DISCARD HORIZONTAL

7/8"GASKET-

SECT. X-X

(TYP. BOTH SIDES)

1/2" GASKET _CREWS TO

INSIDE SURFACE REMOVE COIL

OF BAFFLE

WATER \ _,/"-B

ATER oo

BLOW-OFF ....... oh% ooo

oO DIVERTER ooo

BAFFLES "_ o%0 ooo

. ,.- AFF

ATTACH WITH 7-.J,_%o/f 15TON ONLY/ _\%o_'_,

o°° _ J o

2SCREWS ......

EACH SIDE I " "_ / '-_-"-'

_LL WITH SEALANT

18-GE02D2-4 3

Loading...

Loading...