6

MS-SVN005-EN

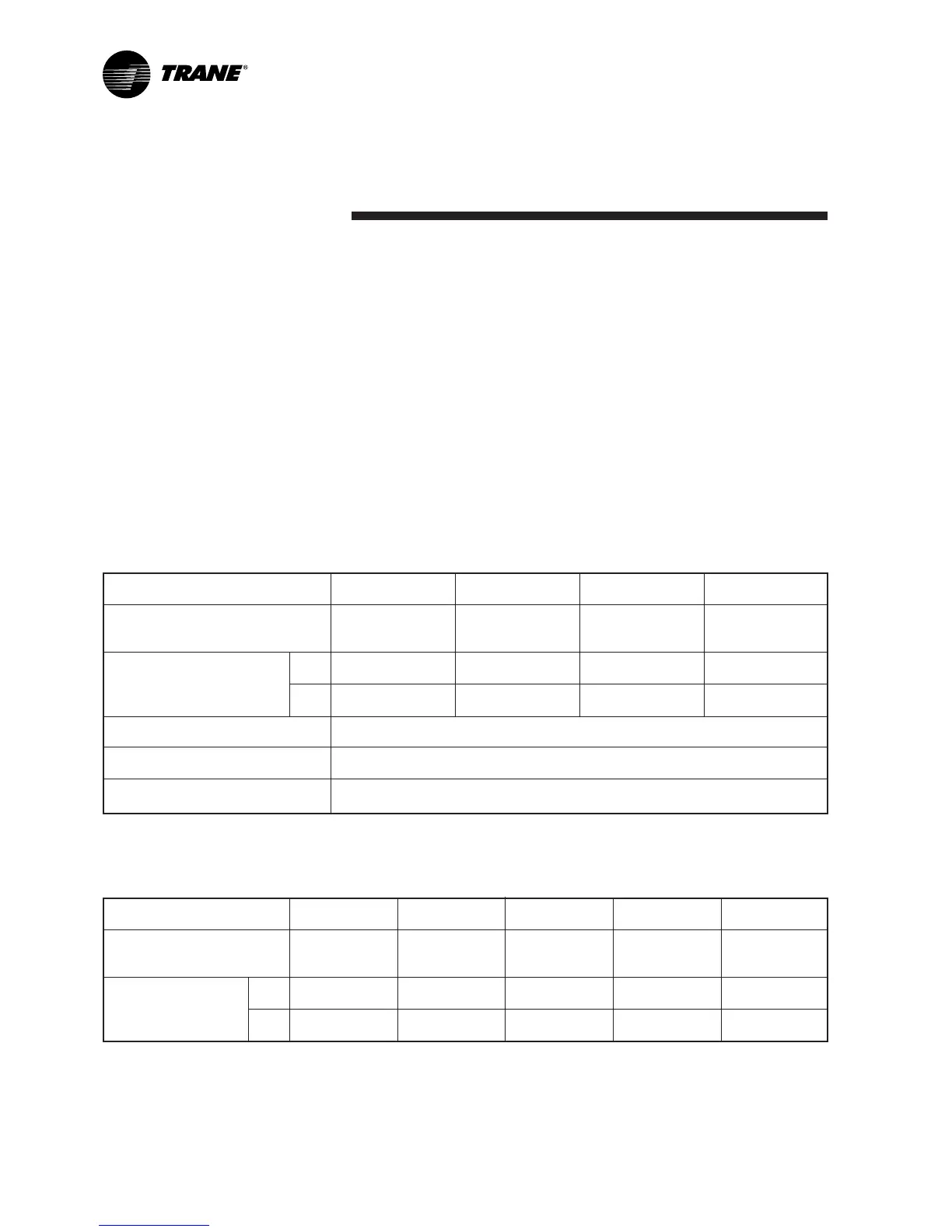

Indoor Unit 507 509 512 518 524/526

Item O.D. O.D. O.D. O.D. O.D.

mm (in) mm (in) mm (in) mm (in) mm (in)

Deoxidized Annealed (L*) 6.35 (1/4) 6.35 (1/4) 6.35 (1/4) 6.35 (1/4) 9.52 (3/8)

Copper Tube (S*) 9.52 (3/8) 9.52 (3/8) 12.7 (1/2) 12.7 (1/2) 15.88 (5/8)

Installation Requirements

Table 2 : For Convertible (MCX), Concealed (MCD) and Hi-Wall (MCW, Frio) Indoor units

1. Copper Tubing

Copper tubing, fittings and

insulation to interconnect the

suction (S) (wide tube) and liquid

(L) (narrow tube) refrigerant lines

between the indoor and outdoor

units can be purchased locally.

It is necessary to purchase the

following items:

- Purchase equal lengths of both

tubes and insulation required.

Cut the appropriate tube lengths,

30 to 40 cm (12 to 16 in.) longer

on each one to deepen vibration

between units. Wall thickness of

copper tube should be 0.8 mm

(0.0314 in.).

Both tubes must be well

insulated with proper insulation

materials.

- The length of wiring will

determine the wire size. See

local codes, refer to section of

electrical installation.

2. Additional Materials

- Saddles or clamps to hold

refrigerant tubing.

- Insulated clamps or staples

for connecting wire.

See local codes.

- Refrigeration oil and tape

(armored).

- Putty or similar filter.

*On Cooling Mode

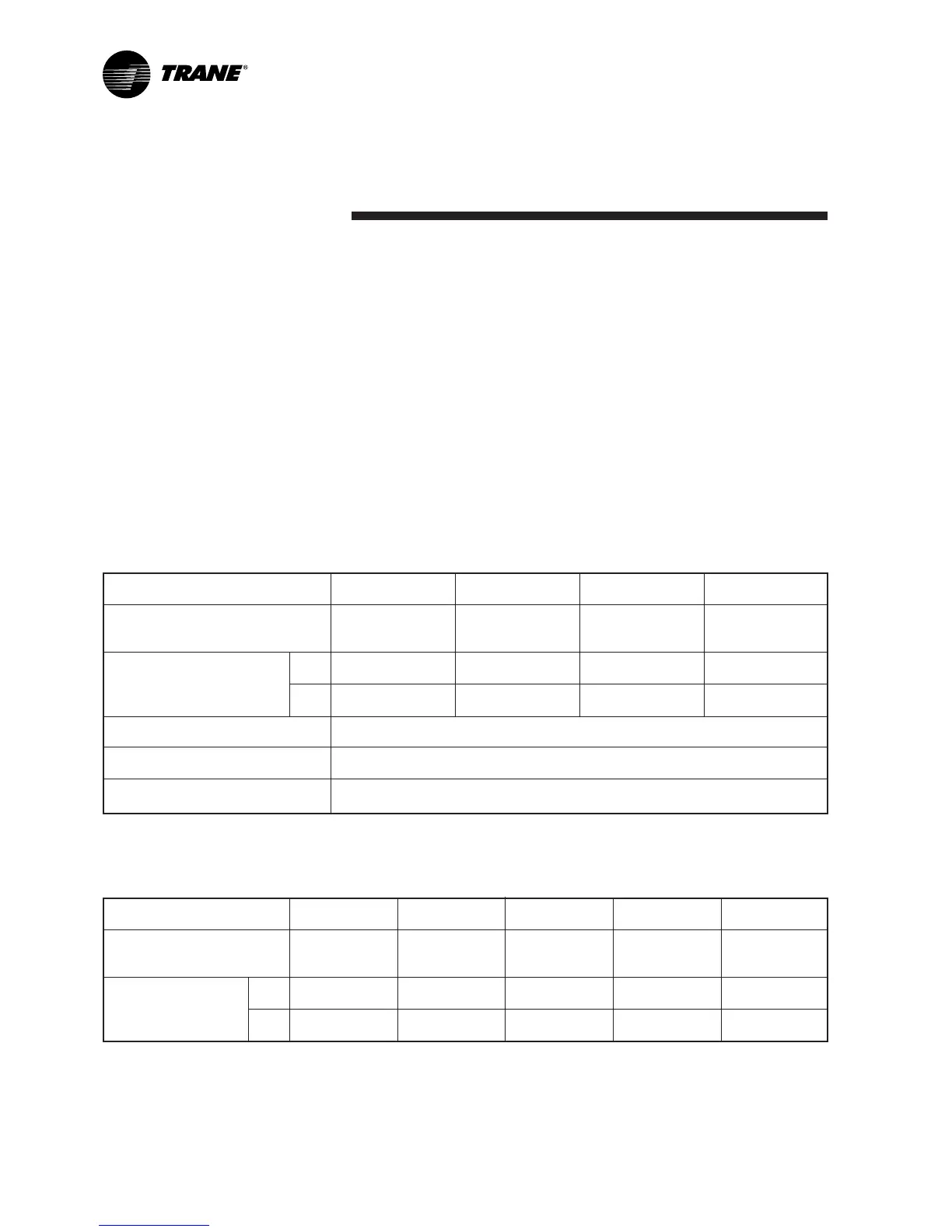

Indoor Unit 509 512 518 524

Item O.D. O.D. O.D. O.D.

mm (in) mm (in) mm (in) mm (in)

Deoxidized Annealed (L*) 6.35 (1/4) 6.35 (1/4) 6.35 (1/4) 9.52 (3/8)

Copper Tube (S*) 9.52 (3/8) 12.7 (1/2) 12.7 (1/2) 15.88 (5/8)

Foamed Polyethylene Diameter : According to O.D. of copper tube

Insulation Thickness : No less than 8 mm (0.3 in)

Insulated Copper Wire Length required to make electrical wiring

Table 3 : For Hi-Wall (MCW, Contura 3G) Indoor units

*On Cooling Mode

Loading...

Loading...