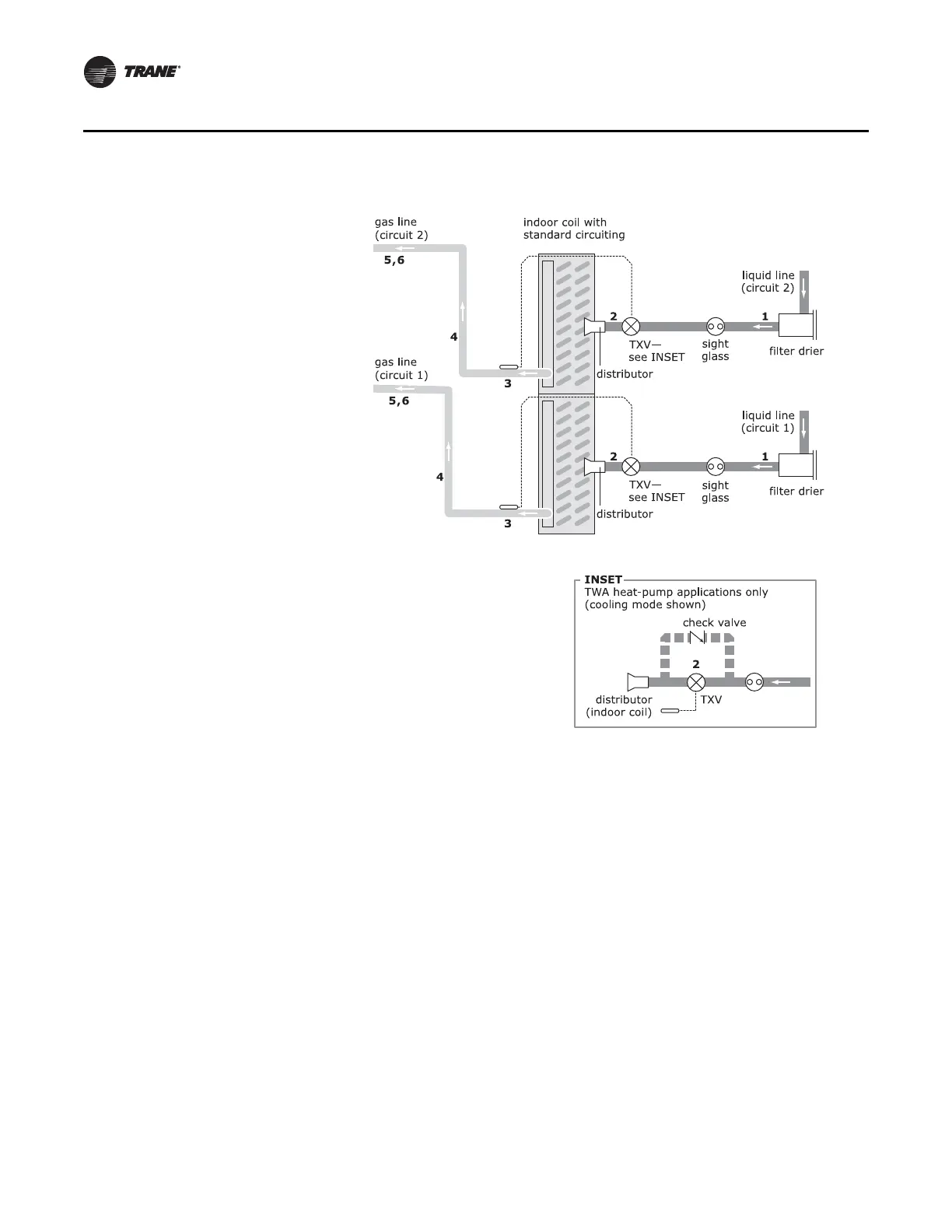

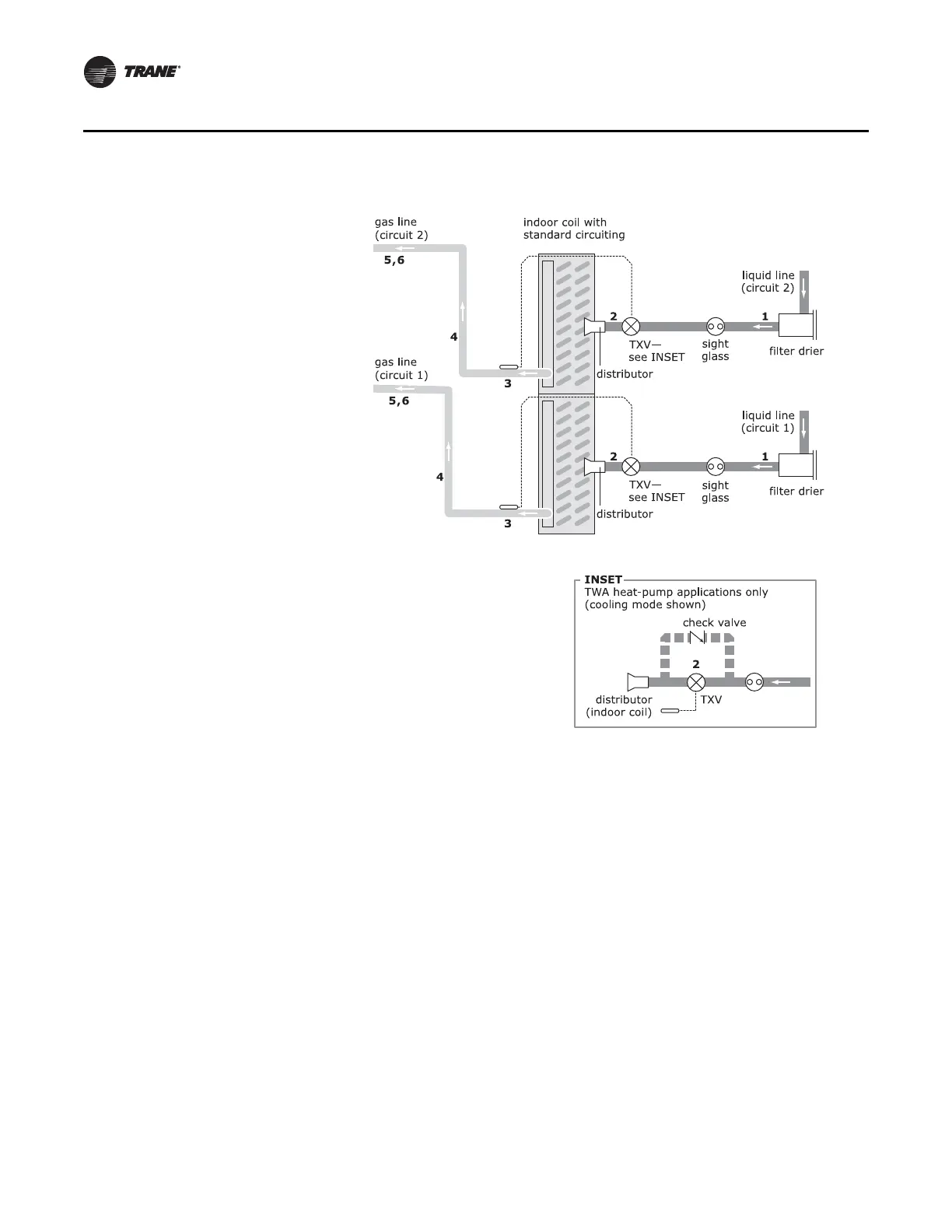

Figure 12. Indoor coil with two distributors (dual-circuit TTA/TWA units)

1 Pitch the liquid line 1 inch per 10 feet (1 cm per

3 m) so that the liquid refrigerant drains toward

the indoor coil. Use the liquid-line size

recommended in Table 2, p. 20, or Table 3, p. 21.

2 Provide one expansion valve (TXV)

per distributor.

TWA heat pumps only: Provide one check

valve for each expansion valve.

3 Pitch the gas line leaving the coil so that it

slopes away from the coil by 1 inch per 10 feet

(1 cm per 3 m).

4 For vertical risers, use the tube diameter

recommended in Ta ble 2 or Ta b l e 3 . Ensure that

the top of the riser is at least 1 foot (30 cm)

above the lowest point.

5 Pitch the gas line 1 inch per 10 feet (1 cm per

3m) toward the indoor coil.

6 Insulate the gas line.

Loading...

Loading...