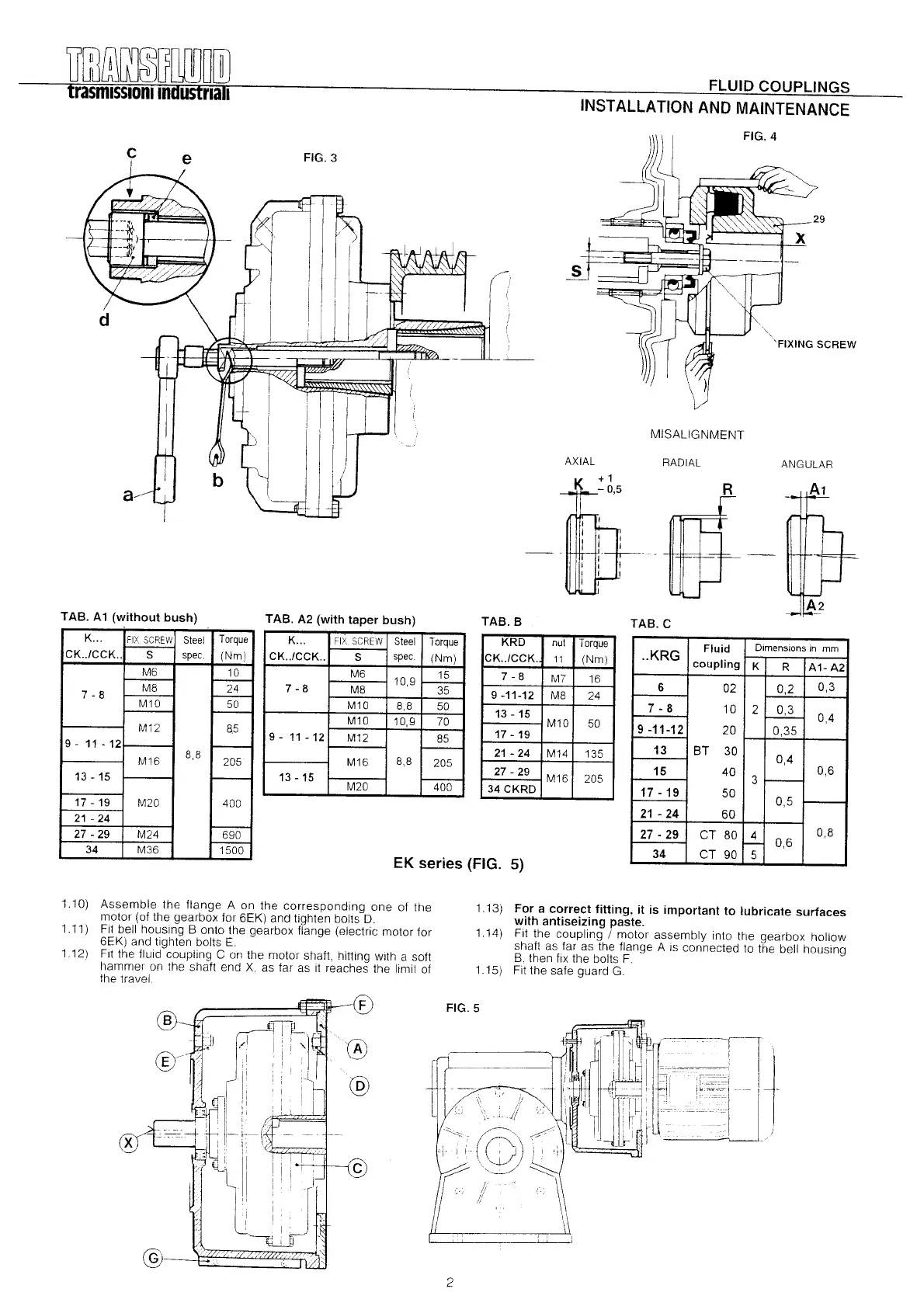

K... FIX SCREW

Steel

T orque

CK../CCK..

S

spec.

(Nm)

M6

10,9

~7-8

M8

35

M10 8,8

50

M10 10,9

70

9-11-12 M12

85

-

M16

8,8

205

13

-

15

~M20

400

KRD nu!

T

orque

CK../CCK,

11

(Nm)

7 - 8

M7

16

9 -11-12

M8

24

13

-

15

M10

50

17

-

19

21

-

24

M14

135

27

-

29

M16

205

34 CKRD

..KRG

Fluid

Dimensions in mm

coupling

K

R

A1- A2

6

02

0,2

0,3

7

-

8

10

2

~0,4

9 -11-12

20 0,35

13

BT

30

0,4

15

40

0,6

3

-

17-19

50

0,5

21

-

24

60

27 - 29

CT 80

..i.

0,8

0,6

34

CT 90

5

M12

85

9-11-12

M16

8,8

205

13

-

15

17

-

19

M20 400

21

-

24

27

-

29

M24

690

34

M36

1500

urnffiwUJ~urn~[[J

trasmlsslom Industrlall

FLUID COUPLlNGS

INST AL LA TION AND MAINTENANCE

)

FIG.4

e

e

FIG.3

29

"",

'FIXING SCREW

MISALlGNMENT

AXIAL

RADIAL

ANGULAR

a

+ 1

-

0,5

R

A1

I

'

I

I

I I

I

I I

I I

¡

I

A2

TAS. A1

(without bush)

K... FIX SCREW Steel T orque

CK..lCCK..

S

spec

(Nm)

M6 10

M8 24

M10 50

TAS. A2

(with taper bush)

TAS. S

TAS.C

7-8

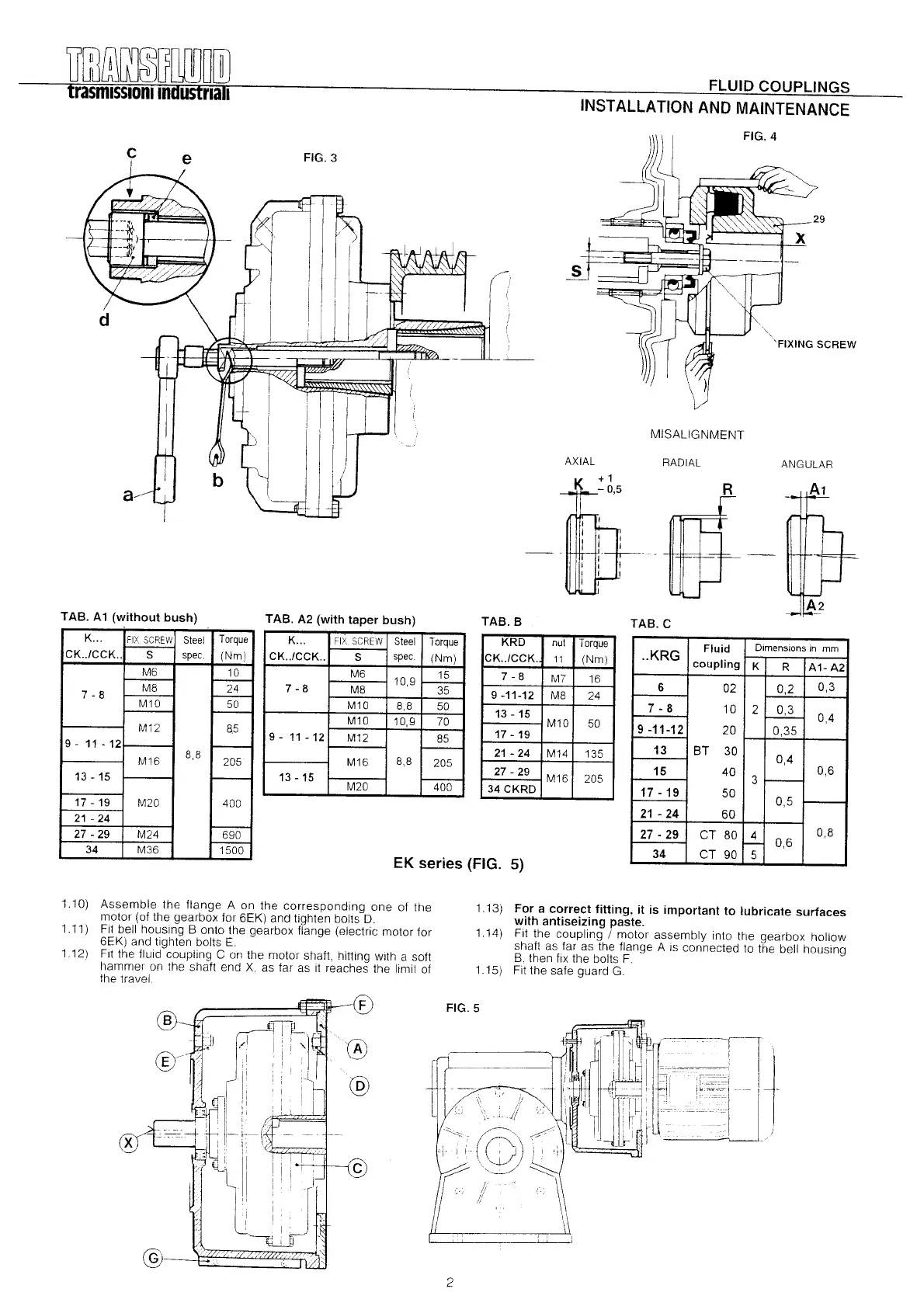

EK series (FIG. 5)

1.10) Assemble the flange A on the corresponding one of the

motor (of the gearbox far 6EK) and tighten bolts D.

1.11) Fit bell housing B onto the gearbox flange (electríc motor for

6EK) and tighten bolts E.

112) Flt the fluid coupling C on the motar shaft, hittíng wlth a soft

hammer on the shaft end X, as lar as it reaches the limit 01

the travel

1.13) For a correct fitting, it is important to lubricate surfaces

with antiseizing paste.

1.14) Fít the coupling / motor assembly into the gearbox hollow

shaft as lar as the Ilange A is connecled lo the bell housíng

B. then lix the bolts F.

1.15) Fit the sale guard G.

CD

FIG.5

:§)

@

@

@

2

Loading...

Loading...