TAB.D2

OIL QUANTITY (11.)

CK... 2 3

4

11

3.350

3.050 2.750

12

4.800 4.200 3.600

13

5.800 5.200 4.700

15

8.600

7.700 6 AOO

17

13.60 12.80

1170

19

16.50

15.20 14.00

21

2300 21.30

1930

24

31.20

28.60 26.00

27

50.00

46.50 43.00

29

6300 59.00

54.00

34

92.50

88.50

83.50

TAB. D1

OIL QUAI'HlTY

(11.)

K... X 1 2

3 4

6

0.505 OA80 OA55

OA25 0.390

7

0.920

0.860 0.800 0730 0.650

8

1.510

1A05

1.295 1.190 1.080

9

1.950

1.820 1.690 1.550

1AOO

11

2.750

2.550 2.350

2.100 1.850

12

4100

3.875 3.575

3.250 2.900

13

5.200 4.850

4A50 4.050

3.600

15

7650

7.150 6600 6.000 5AOO

17

11.70 10.90

10.00 9.100

8.200

19

14.20

13.30 12.30

11.20 10.00

21

19.00

17.80

16AO 15.00

1350

24

28 AO

26.50

2460 22.60

20.50

27

42.00

39.00 36.00

33.50

31.50

29

55.00 51 00

47.00 44.00

41.50

34 82.50

76.60

70.60

66.20

62.50

TAB.D3

OIL QUANTITY (11.1

CCK...

3

4

15

9.30

8.00

17

16.36

14.86

19

18.76 16.86

21

2730

24.30

24

35A3 31.63

27

59.35 55.15

29

70.60 65.20

34 96.70

86 AO

SIZE

CUSIBLE PLUG

O.nolT]

l. ,C,;?TorquE- iNmj

6 hb

12

1/2'

7

-

8

-

9

88

23

í/4

11

12

13

-

15

17-

19

ceo 29

31e'

21

,24

27

-

29

8E::

44

34

TIrnffiw~üllillu[]

trasmlsslom mdustnall

2. FLUID COUPLlNGS FILLlNG INSTRUCTIONS

KR... - KSD - EK SERIES

TI'ansfluld fluld coupllngs are no! supplled wlth 011

Therelore 11IS necessary to achleve the lollowlng pracedure:

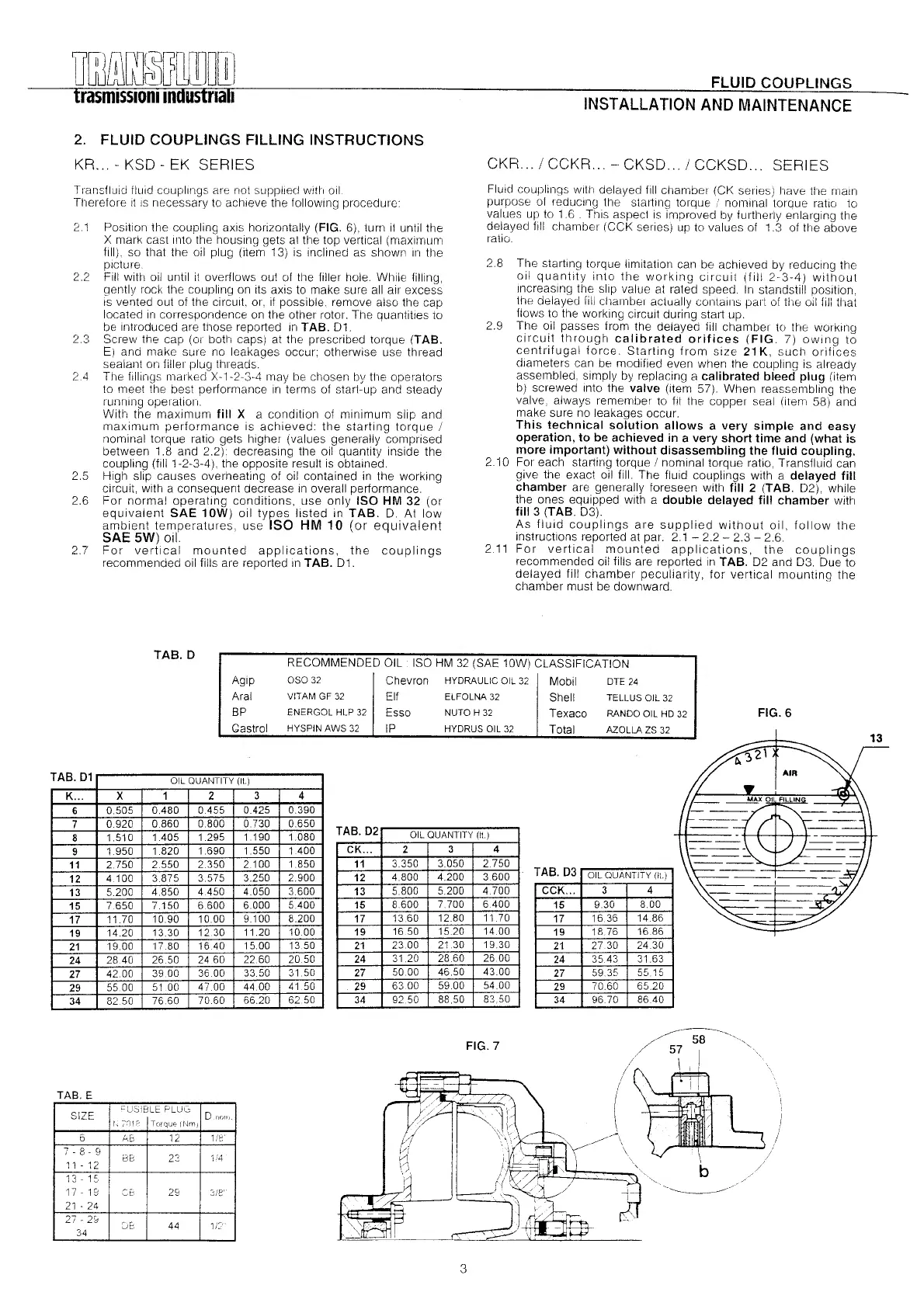

2.1 Positlon the coupllng axls horizontally (FIG. 6). turn I1until the

X mark cast Into the houslng gets al tlle top vertical (maxlmum

fill). so that tlle 011plug (item 13) Is Inclined as shown III the

plcture

FIII wlth 011untll it overflows out 01 the filler hole. Whlle fllllng,

gently rack the coupllng on its axls to make sure all air excess

IS vented out of the clrcult, 01', If posslble. remove also tlle cap

located In correspondence on the other rotor. The quantltles to

be Intraduced are those reported in TAB. 01.

Screw the cap (or both caps) at the prescribed torque (TAB.

E) and make sure no leakages occur; otherwise use thread

sealant on filler plug tllreads.

The líllings marked X-1-2-3-4 may be chosen by the opel'ators

to meet the be sI performance In terms 01 start-up and steady

runnlng operatíon.

With the maxlmum fill X a conditlon 01 mlnlmum slip and

maxlmum performance Is achieved: the startlng torque !

nominal torque ratlo gets higher (values generally comprised

between 1.8 and 2.2) decreaslng the 011quantlty Inslde the

coupling (fII11-2-3-4), the opposite result Is obtained.

HIgh slip causes overheating of 011contalned in the worklng

circuit, wlth a consequent decrease IIIoverall performance.

For normal operatlng conditions, use only ISO HM 32 (01'

equivalent SAE 10W) 011 types listed in TAB. O. At low

amblent temperatures, use ISO HM 10 (01' equivalen!

SAE 5W) ol!.

For vertical mounted appllcatlons, the coupllngs

recommended 011fllls are reported in TAB. 01.

22

2.3

24

2.5

2.6

27

TAB.D

FLUJD COUPLlNGS

INST ALLA TION

AND MAINTENANCE

CKR... / CCKR... - CKSD... / CCKSD... SERIES

Fluid couplillgS Wltll delayed IIIIchambel (CK series) have the mal n

purpose ot reduclng tlle startíng torque / nominal torque ratlo to

values up to 1.6 . Thls aspecl Is Improved by furtherly enlarglng the

delayed flll chambel (CCK series) up to values of 1.3 of the above

ratío

2.8 The startíng torque Ilmítatlon can be achieved by reducíng the

oil quantlty ínto the worklng clrcult (till 2-3-4) without

IIlcreaslng the slip value a! rated speed. In standstill positlon,

the delayed lill chambel actually COlltalllS par! 01 the oil II11that

Ilows to the working clrcuit durlng start up.

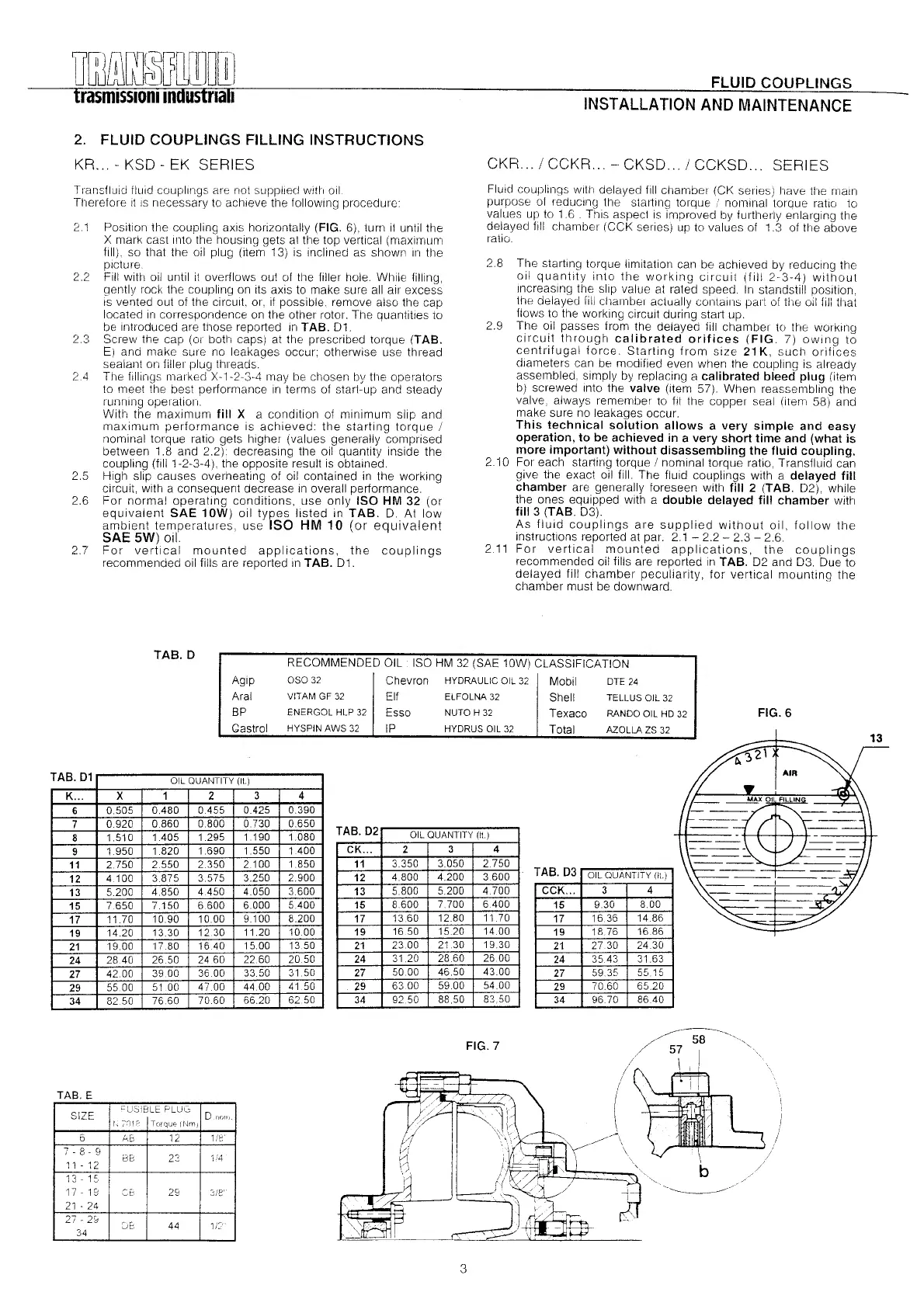

2.9 The 011 passes Irom the delayed IIII chamber to the workíng

clrcuit tllrough calibrated orifices (FIG. 7) oWlng to

centnlugal lorce. Starting Irom slze 21 K, such orillces

dlameters can be modílied even when the coupllng is already

assembled, slmply by replacing a calibrated bleed plug (item

b) screwed IIlto the valve (Item 57). When reassembling the

valve, always remember to flt the copper seal (Item 58) and

make sure no leakages occur.

This technical solution allows a very simple and easy

operation, to be achieved in a very short time and (what is

more important) without disassembling the fluid coupling.

210 For each starting torque ! nominal torque ratío, Transfluld can

give the exact oíl lill. The Iluíd coupllngs with a delayed fill

chamber are generally foreseen with fill 2 (TAB. 02), while

the ones equlpped wlth a double delayed fill chamber with

fill 3 (TAB. 03).

As fluid couplings are supplied without 011, lollow the

instructlons reported at par. 2.1 - 2.2 - 2.3

-

2.6.

211 For vertical mounted appllcatlons, the coupllngs

recommended oíl fills are reported In TAB. 02 and 03. Oue to

delayed lill chamber peculiarity, for vertical mounting the

chamber must be downward.

Aglp

Aral

BP

Castrol

RECOMMENDED OIL ISO HM 32 (SAE 10W) CLASSIFICATION

OSO 32 Chevron HYDRAULlC OIL 32 Mobil DTE 24

VITAM GF 32 El! ELFOLNA 32 Shell TELLUS OIL 32

ENERGOL HLP 32 Esso NUTO H 32 T exaco RANDO OIL HD 32

HYSPIN AWS 32 IP HYDRUS OIL 32 Total AZOLLA zs 32

FIG.6

~~.,.,

1/

.

/

~

/

..

57\.

...

:

.......

I

....

"',

(

"

",

~..-\

..

.~ \ .

:

I \

\

/

~// b

rl~

~

l

.

'"

...

:I~

.

~

..

¡

J

{1/

,

,

~

FIG.7

TAB.E

/

-,~.-

3

Loading...

Loading...