:z:

o

o

w o..

¡:::

o

w

:::o

« «

o..

I

Dé

o

UJ

>-

W

-'

FIG.13

Dé

o..

Dé

«

o

w

>-

>

UJ

o

ITrnmwg)Uilllfl~rn

trasmlsslom Industrlall

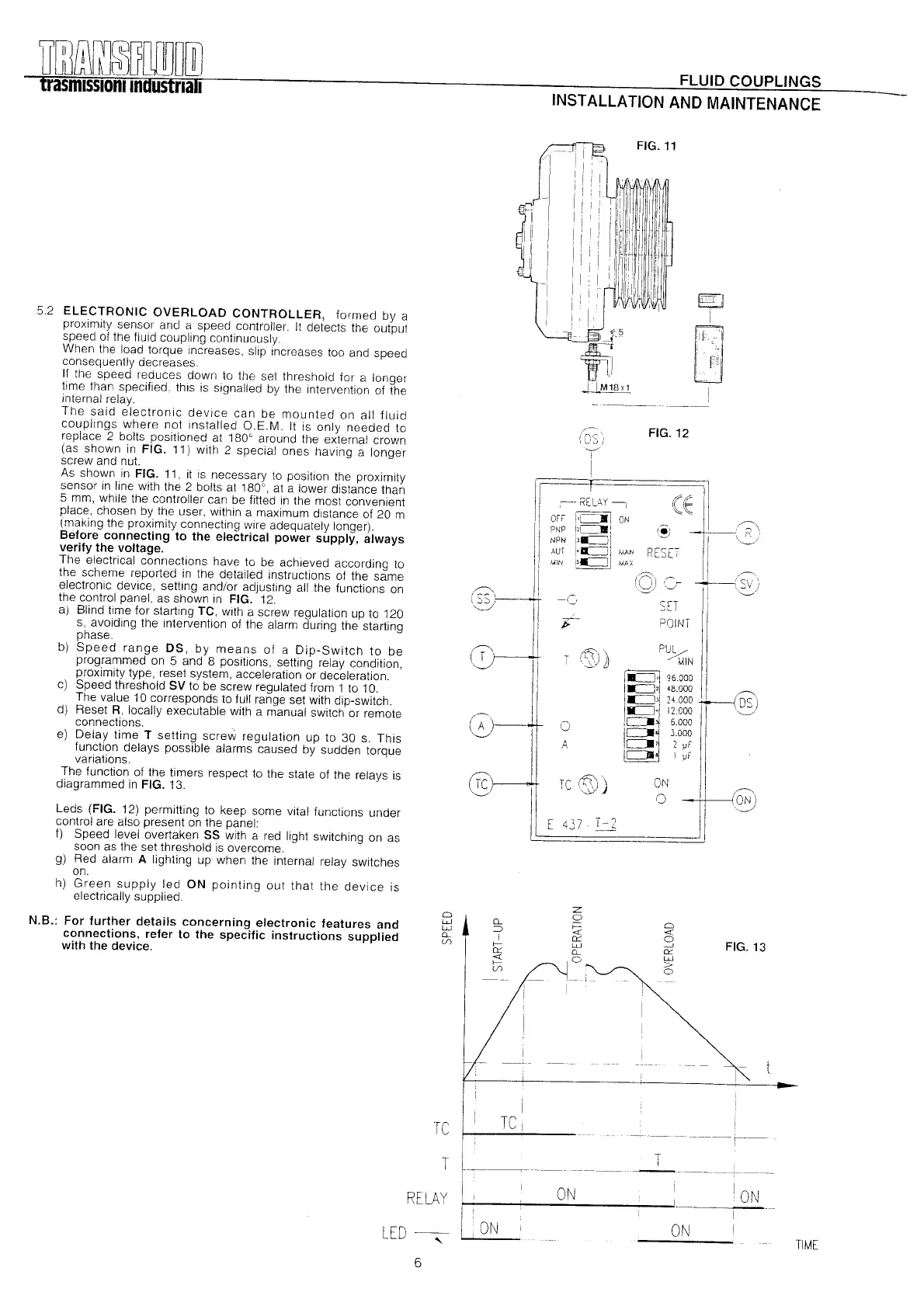

5.2 ELECTRONIC OVERLOAD CONTROLLER, formed by a

proximity sensor and a speed controller. It detects the output

speed of the fluid coupling continuously.

When the load torque increases, slip increases too and speed

consequently decreases.

II the speed reduces down to the set threshold far a longer

time than specified, thls is signalled by the intervention 01 the

internal relay.

The said electronic device can be mounted on all fluid

couplings where not installed O.E.M. It is only needed to

replace 2 bolts positioned at 180' around the external crown

(as shown in FIG. 11) with 2 special ones having a longer

screw and nut.

As shown in FIG. 11, it is necessary to position the proximity

sensor in line with the 2 bolts at 180°, at a lower distance than

5 mm, while the controller can be fitted in the most convenient

place, chosen by the user, within a maximum distance of 20 m

(making the proximity connecting wire adequately longer).

Before connecting to the electrical power supply, always

verify the voltage.

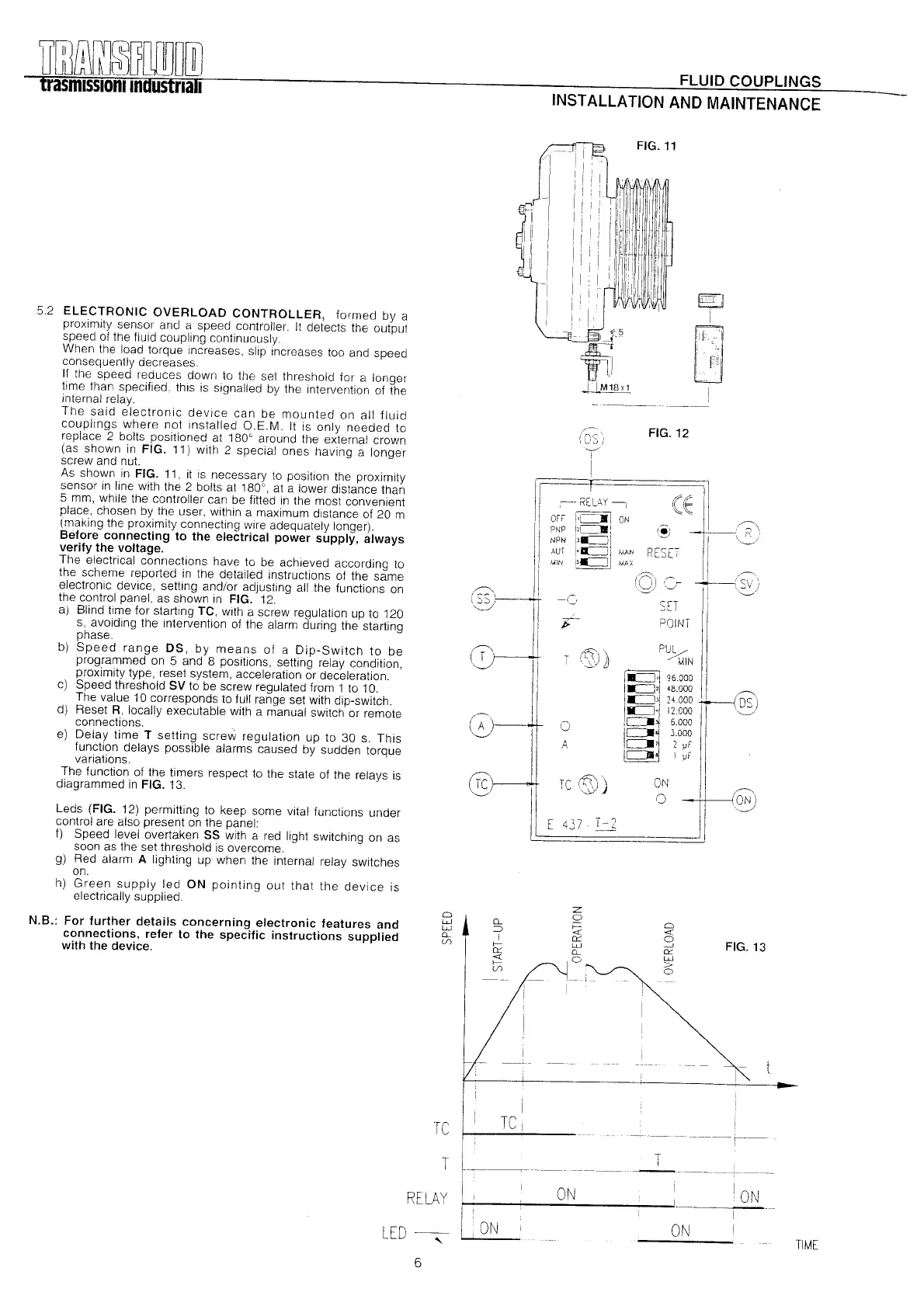

The electrical connections have to be achleved according to

the scheme reported in the detailed instructions 01 the same

electronic device, setting and/or adjusting all the functions on

the control panel, as shown In FIG. 12.

a) Blind time lor starting TC, wlth a screw regulation up to 120

s, avoiding the intervention of the alarm during the starting

phase.

b) Speed range DS, by means 01 a Dip-Switch to be

programmed on 5 and 8 positions, setting relay condition,

proximity type, reset system, acceleration or deceleration.

c) Speed threshold SV to be screw regulated from 1 to 10.

The value 10 corresponds to full range set with dip-switch.

d) Reset R, locally executable with a manual switch or remote

connections.

e) Delay time T setting screw regulation up to 30 s. This

lunction delays possible alarms caused by sudden torque

variations.

The lunction of the timers respect to the state of the relays is

diagrammed in FIG. 13.

Leds (FIG. 12) permitting to keep some vital lunctions under

control are al so present on the panel:

1) Speed level overtaken SS with a red light switching on as

soon as the set threshold is overcome.

g)

Red alarm A lighting up when the internal relay switch es

on.

h) Green supply led ON pointing out that the device is

electrically supplied.

N.B.: For further details concerning electronic features and

connections, refer to the specific instructions supplied

with the device.

LED~

6

RELAY

FLUID COUPLlNGS

INST ALLA TION AND MAINTENANCE

FIG.11

~

¿I

:1

f'l

--~~~----

11

11

,1

l'

11

11

I~'

I!

I¿Y-~

:1

/-.

1:OS)

--.,/

I

I

f

~.

REL4Y-,

OFF

1" -IoN

PNP ¡,c=JIi

NPN

!J-=:J!

AUT

l'

a::=J!

\AAN

MIN

1).':" ~I

\AAX

(E 1]

'.' ~~\

RE~~T

I1

'~I

~ I1 /~

1,--/1-

~\,.:~~:/)

SET

POINT

FIG.12

-(=¡

T

- (D:'i\

1

'.:Y

j)

P%

MIN

IIL H 96000

I

-=:J'I

48.000

-=:J,I

24.000

rr--<DS)

..:=J,¡

12.000 .'-.,./

,c=JI~ 6.000

1

: =::~

3000

c=JI'

2 ~F

ic:JI I ~F

(]

A

@

11

[!4CJ~i)¡

ON

(]

,~

ON)

''-.,./

TC

TIME

T

T

I

--------

~--~------

ON ION

ON

Loading...

Loading...