8 VSD2H Variable Speed Drives Data Sheet TA201104 Issue 3, 08-Oct-2013

VSD2H Data Sheet

INSTALLATION

CLEARANCES

The Trend VSD2H drive must be installed in a vertical position. It can be mounted on a wall or in an enclosure using four screws or

bolts. The cooling airow to the drive must not be blocked in any way, recirculation of air inside the enclosure should be avoided.

Different acts of maintenance also require certain amount of free space.

Make sure that the temperature of the cooling air does not exceed the maximum ambient temperature of the converter.

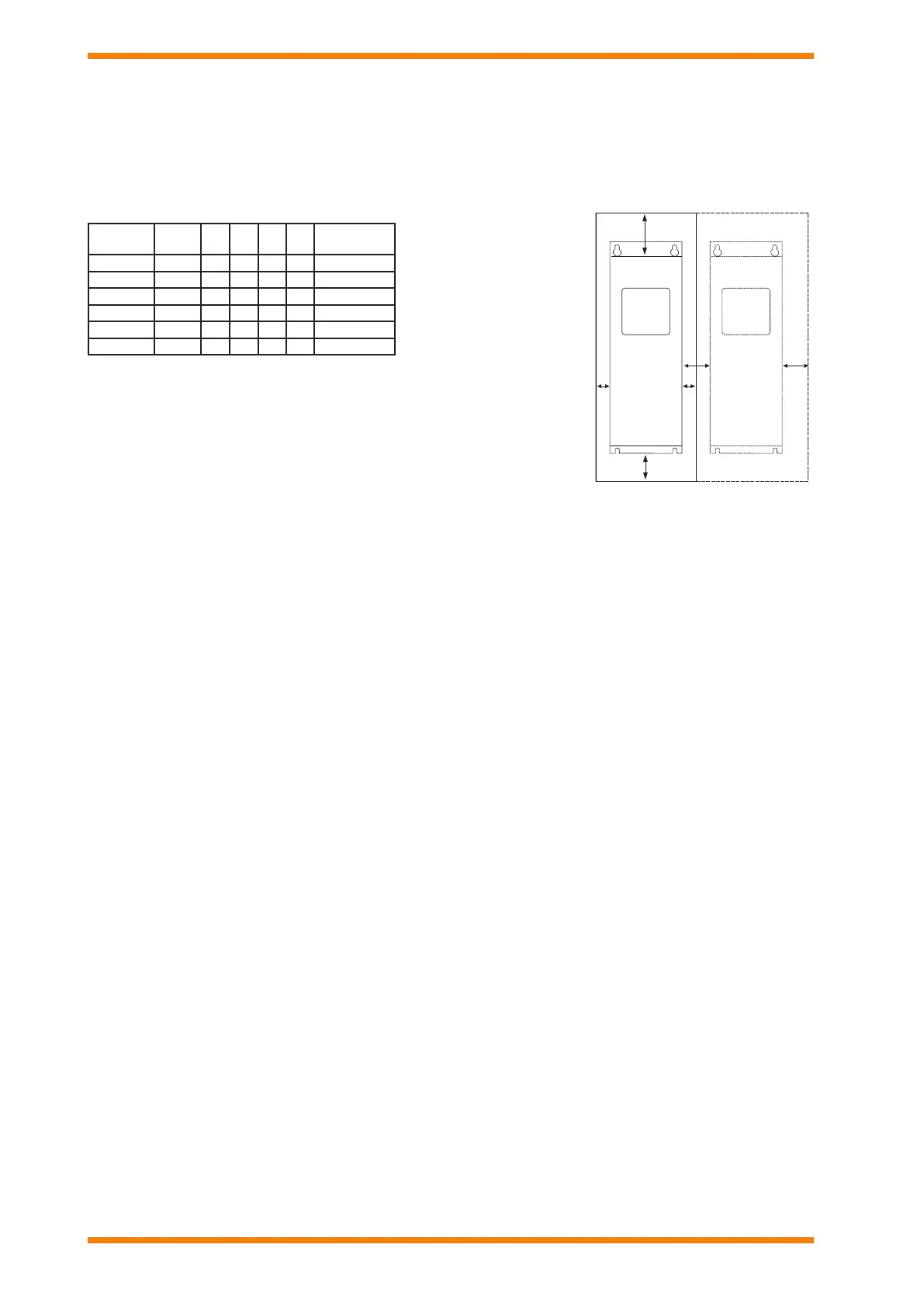

Key:

A: clearance around the freq. converter (see also B)

B: distance between two drives or distance to cabinet wall

C: free space above drive

D: free space below drive

If several units are mounted above each other the required space between them equals C+D. Also the outlet air used for cooling the

lower unit must be directed away from the inlet air to be used by the upper unit.

INSTALLATION PROCEDURE

Overload protection of the supply cable should be considered (e.g. fuses). The use of shielded motor cables is recommended; they

should be routed as far away from other cables as possible, and cross other cables at right angles. The motor cable shield should

be grounded at both the VSD2H drive and at the motor.

The installation involves:

mount the controller in position

connect mains cable

connect motor cable

check mains and motor cable insulation

connect control cable

check quality and quantity of cooling air

check inside of drive for condensation

set up DIP switches

check all start/stop switches connected to I/O are at stop

switch on power to drive

congure the drive (e.g. using the keypad)

perform run test without motor

commission with motor connected

This installation procedure, is covered by the Trend VSD2H Installation Manual, TE201102.

MODBUS installation is covered by the MODBUS Protocol Installation and User’s Manual TE201235

BACnet installation is covered by the BACnet Protocol Installation and User’s Manual TE201234

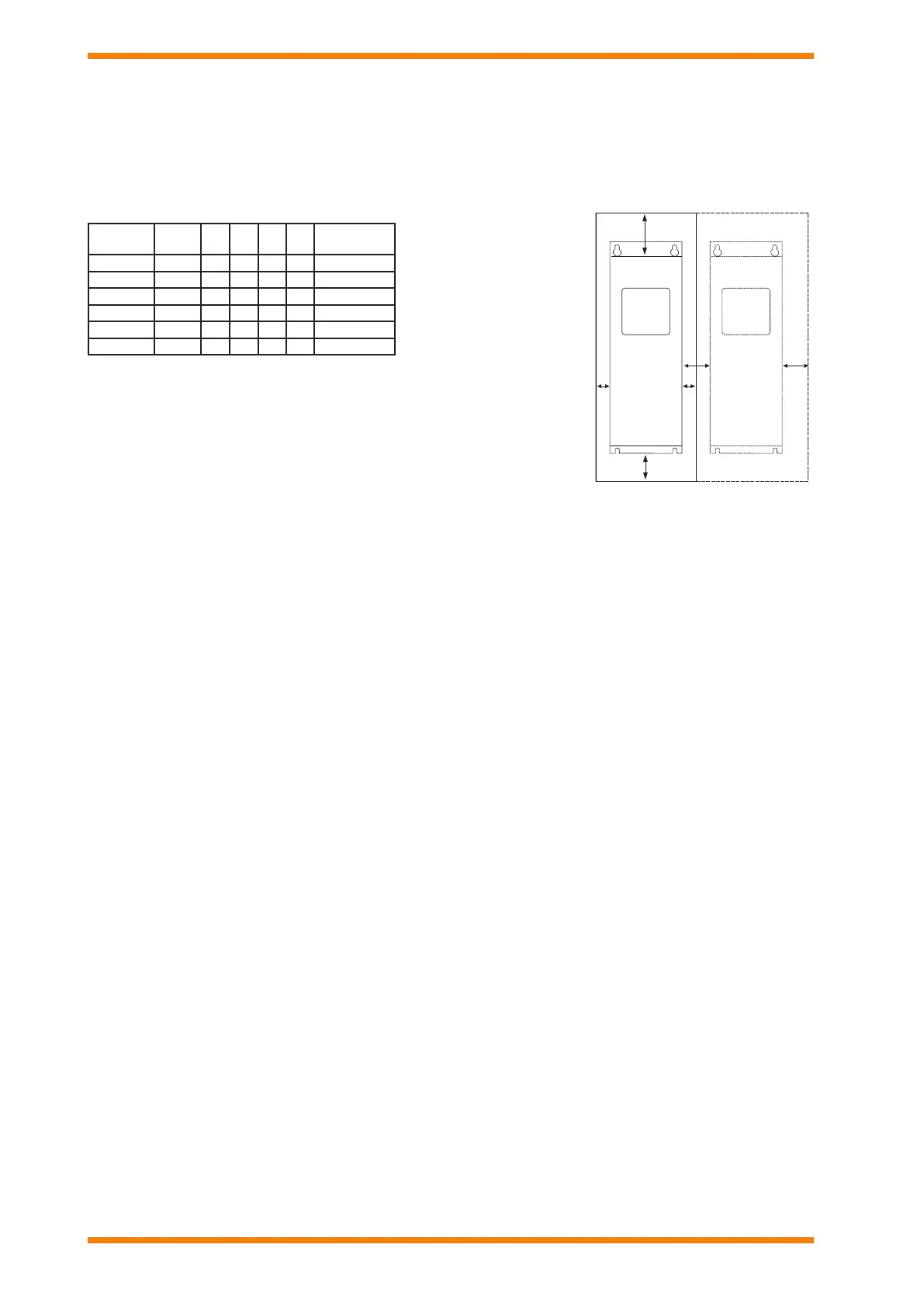

Current (A) Frame *A *B C D

Cooling Air

Required m

3

/h

3 to 12 MR4 20 20 100 50 45

16 to 31 MR5 20 20 120 60 75

38 to 61 MR6 20 20 160 80 190

72 to 105 MR7 20 20 250 100 185

140 to 205 MR8 20 20 300 150 335

261 to 310 MR9 20 20 350 200 621

* Minimum clearances A and B

for drives with IP54 enclosure

is 0 mm

Loading...

Loading...