RUNNING ADJUSTMENTS-Engine

A

new gasket must be fitted each time the cylinder head is removed.

The plain side of the gasket must be downwards against the cylinder

block and should be coated on both sides

with

cc

WELLSEAL" or

similar non-setting sealing compound.

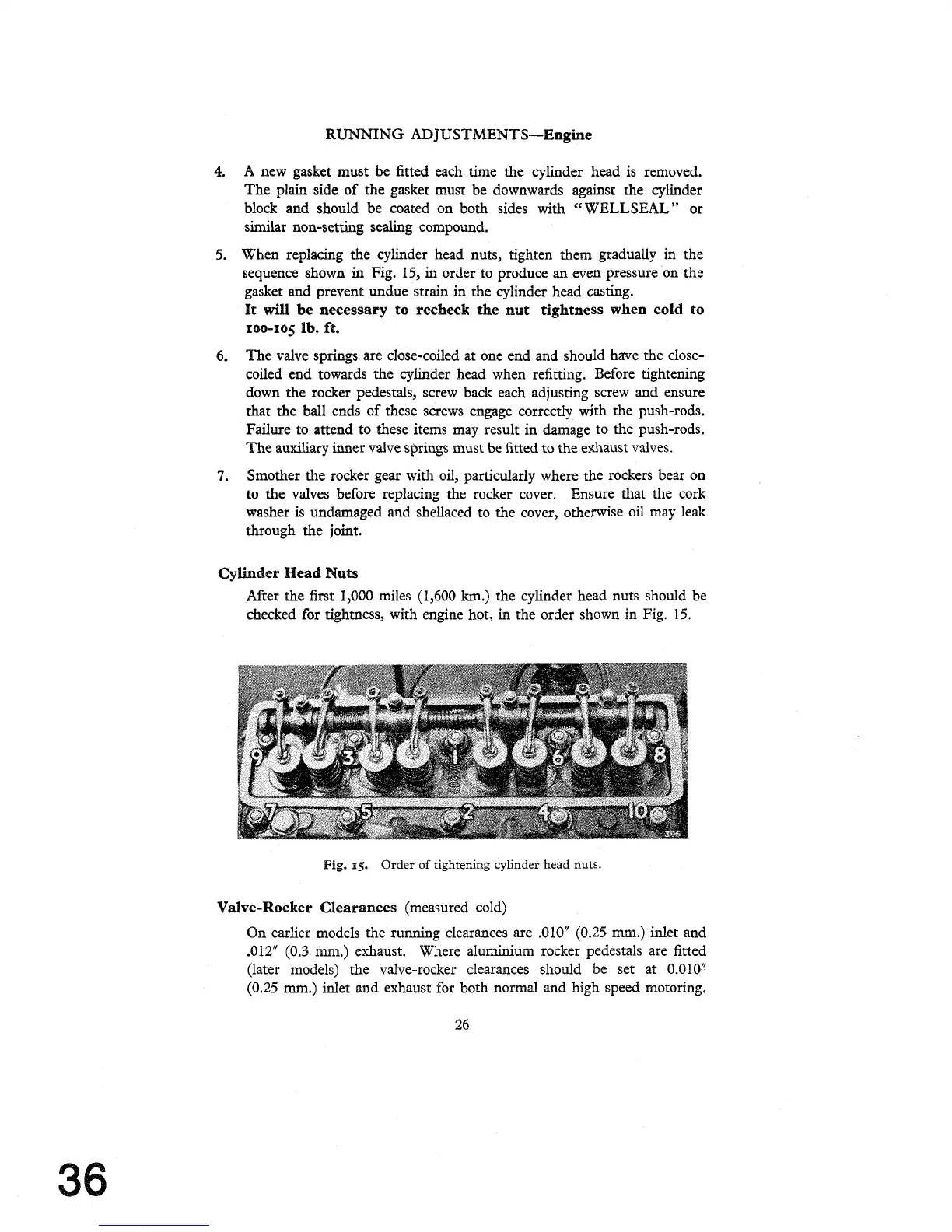

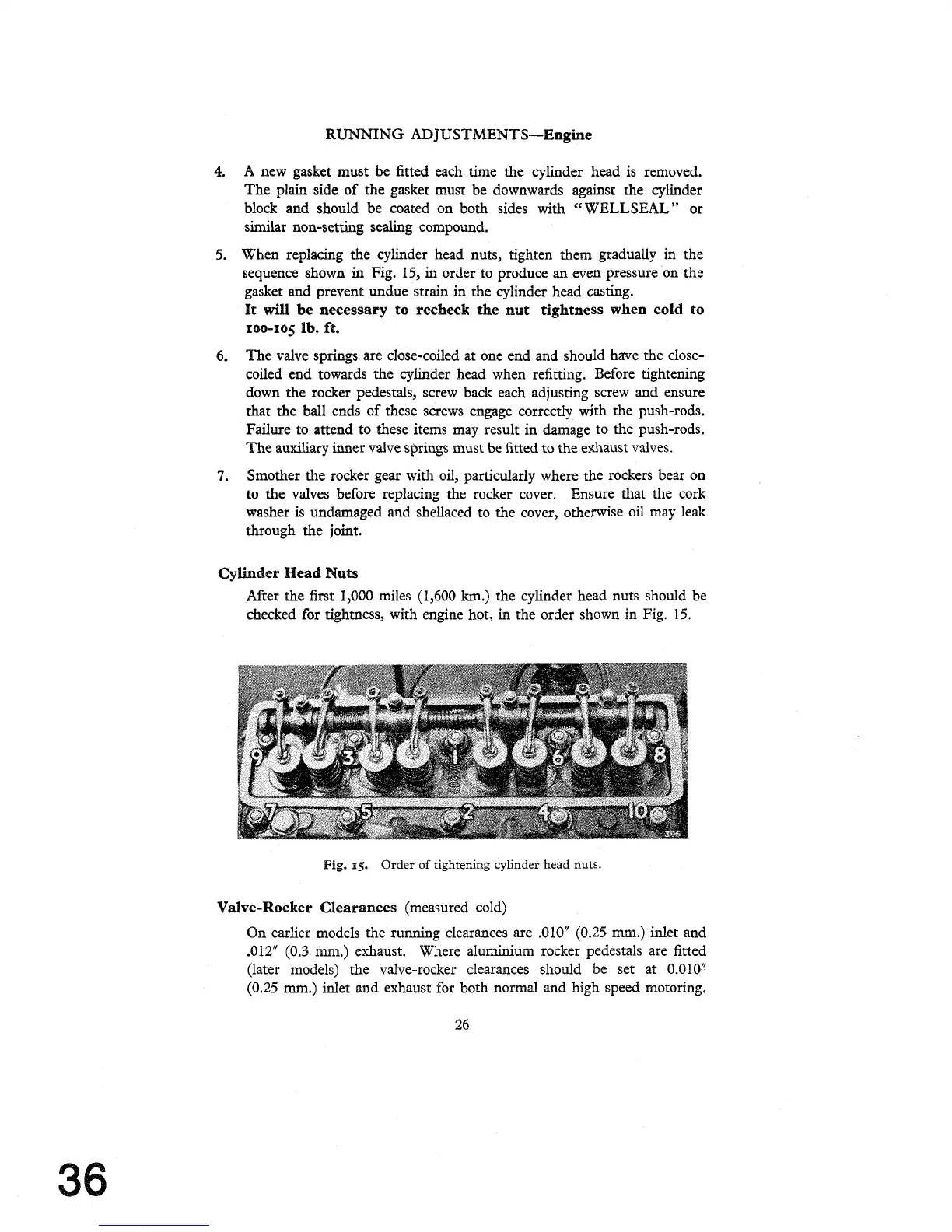

When replacing the cylinder head nuts, tighten them gradually in the

sequence shown in Fig.

15,

in

order to produce

an

even pressure on the

gasket and prevent undue strain in the cylinder head casting.

It

will

be necessary to

recheck

the nut tightness when cold to

loo-105

lb.

ft.

The valve springs are close-coiled at one end and should have the close-

coiled end towards the cylinder head when refitting. Before tightening

down the rocker

pedestals, screw back each adjusting screw and ensure

that the ball ends of these screws engage correctly with the push-rods.

Failure to attend to these items may result in damage to the push-rods.

The

adary her valve springs must

be fitted to the exhaust valves.

Smother the rocker gear with oil, particularly where the rockers bear on

to

the valves before replacing the rocker cover. Ensure that the cork

washer is undamaged and

shellaced to the cover, otherwise oil may leak

through the joint.

After the first 1,000 miles (1,600

km.) the cylinder head nuts should be

checked for tightness, with engine hot, in the order shown in Fig.

15.

Fig.

15.

Order

of

tightening cylinder

head

nuts.

Valve-Rocker Clearances (measured cold)

On

earlier models the running clearances are .010" (0.25 mm.) inlet and

.012" (0.3

mm.) exhaust. Where aluminium rocker pedestals are fitted

(later models) the valve-rocker clearances should be set at 0.010"

(0.25

mm.) inlet and exhaust for both normal and high speed motoring.

Loading...

Loading...