RUNNING

AD

JUSTMENTS-Engine

Sparking

Plugs

The sparking plugs were adopted for original equipment after lengthy

tests and as sparking plug types vary in suitability for different engines,

it is important that the correct type of plug be fitted when making

replacements, this is

:

Champion No. LlOS-$" reach.

In countries where the octane rating of the fuel is low, making it

necessary to use the lower compression ratio, it

may

be desirable to use

Champion

L10

plugs.

For high speed touring however, use Champion No.

L11S-y reach.

The gaps

(i.e.,

the width between the firing point of the centre electrode

and earth point) are originally set and should

he

maintained at 0.025"

(0.62

mm.).

Incorrect gap settings may cause misfiring or erratic slow

running. Faulty plug leads or cracked porcelain insulation in the sparking

plug

will also cause faulty

ignition, see also page

9.

Sparking plugs should be thoroughly cleaned, checked and adjusted (if

necessary) for gap setting after 6,000 miles (10,000 km.) use and at

12,000 miles (20,000 km.) should be replaced by new plugs.

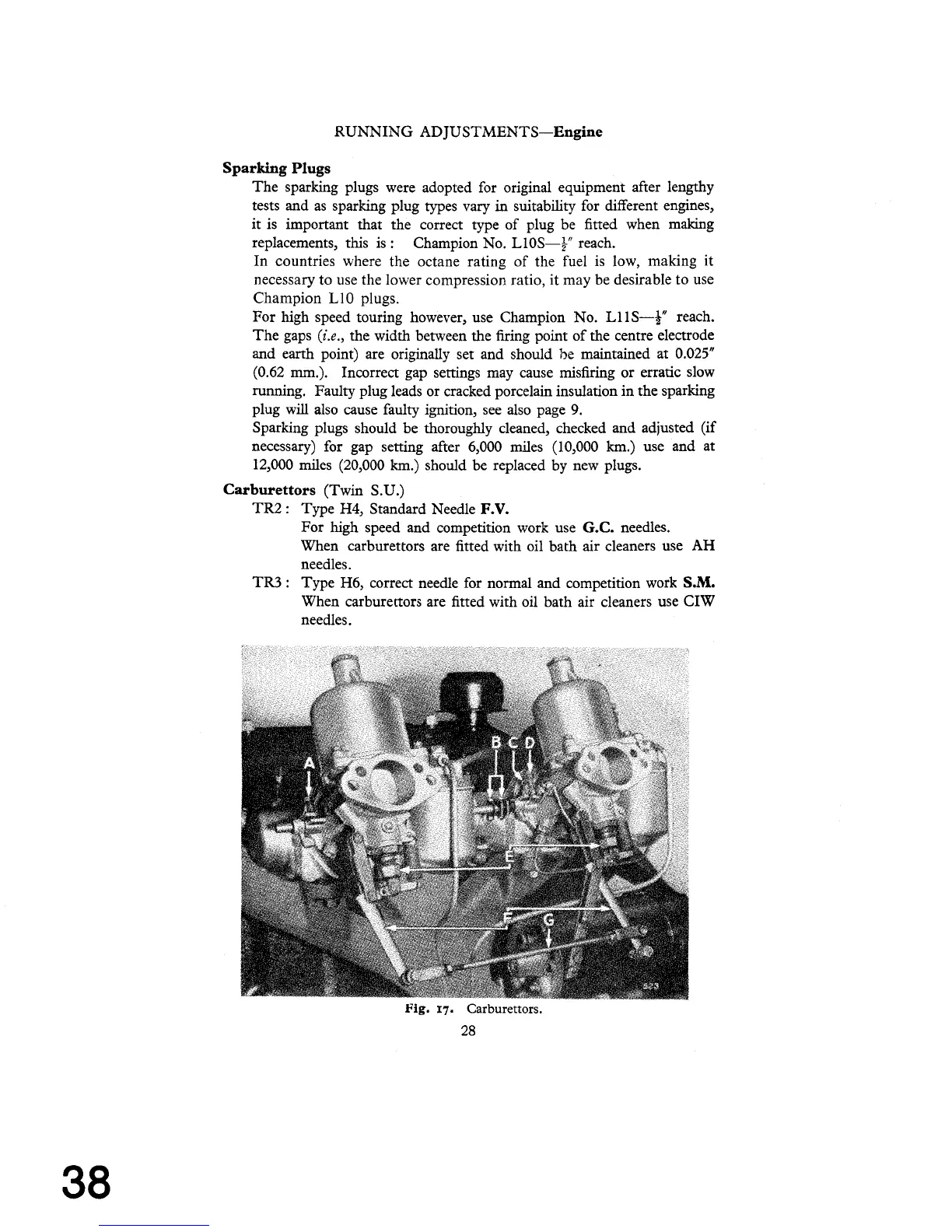

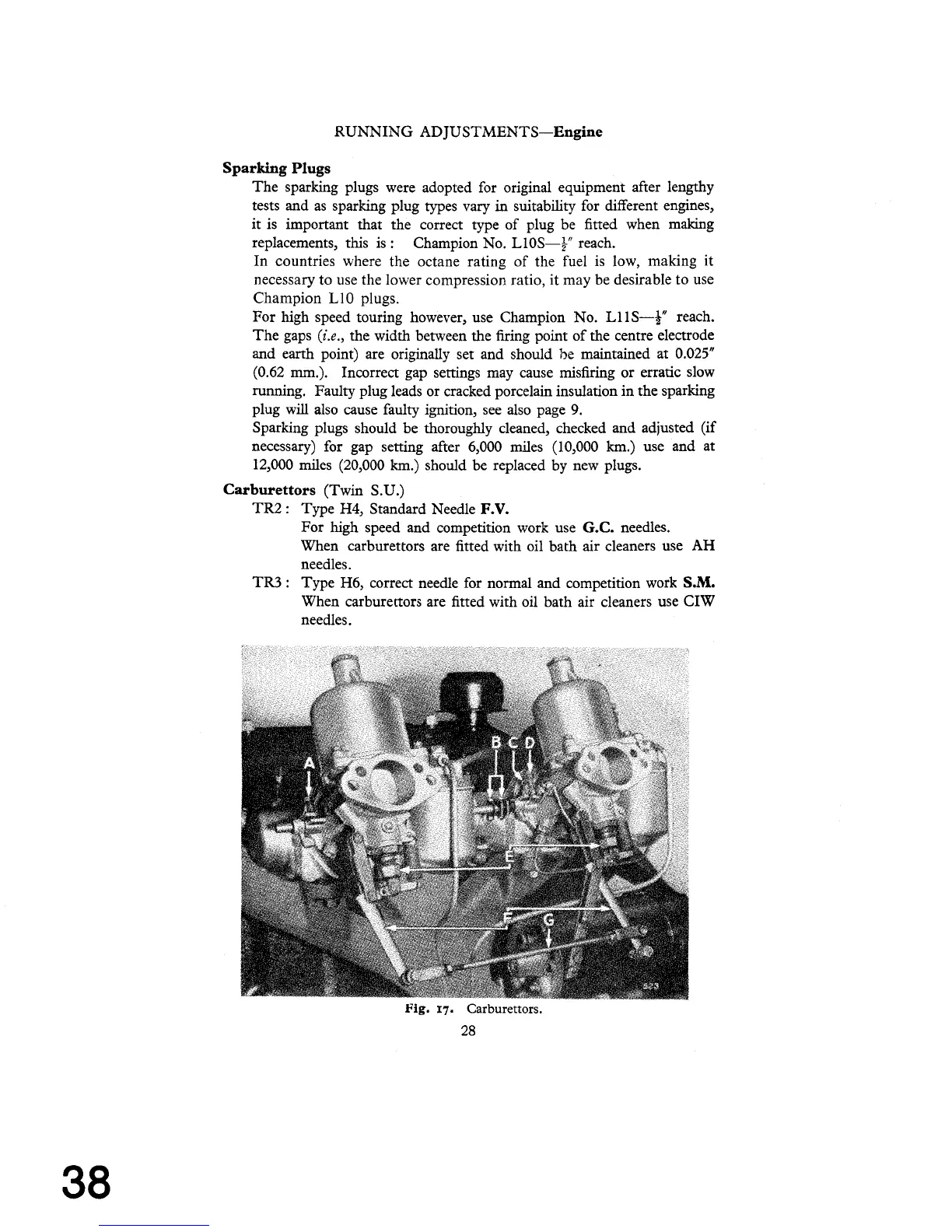

Carburettors (Twin S.U.)

TR2

:

Type H4, Standard Needle

F.V.

For high speed and competition work use G.C. needles.

When

carburettors are fitted with oil bath air cleaners use

AH

needles.

TR3

:

Type H6, correct needle for normal and competition work

S.M.

When carburettors are fitted with oil bath air cleaners use CIW

needles.

Fig.

17.

Carburettors.

Loading...

Loading...