FRONT SUSPENSION AND STEERING

(h)

Place the rebound rubber abutment

\,

plate in position on the lower attach-

ment studs (welded to the spring pan)

with the apex of the wedge pointing

towards the centre of the car. Secure

with nuts and lock washers.

(i)

Utilising two long bolts, nuts and lock

washers secure the rebound rubber and

its bracket to the chassis frame.

(j)

Remove the lifting jack from under the

lower wishbones and replace the road

wheel.

(k)

Jack up front of car to remove support

stands, finally remove jack.

12.

TO REMOVE FRONT ROAD

SPRING

(a)

Remove front shock absorber as de-

scribed on page

8.

(b)

Withdraw the split pins from the

castellated nuts on the underside of the

lower wishbones. Remove the centre

nut and bolt from the front wishbone

arm and the bump rubber assembly

from the rear wishbone arm. Feed

two guide pins into the vacant holes.

(c)

Place a small lifting jack under the

spring pan, with a suitable packing

between jack and pan to prevent darn-

age to the shock absorber attachment

studs on the latter.

(d)

Remove the four remaining nuts secur-

ing the spring pan to the wishbone

arms and lower jack, easing the guide

pins through the wishbone

arms.

(e)

The spring can be withdrawn from its

upper abutment together with rubber

washers and distance piece.

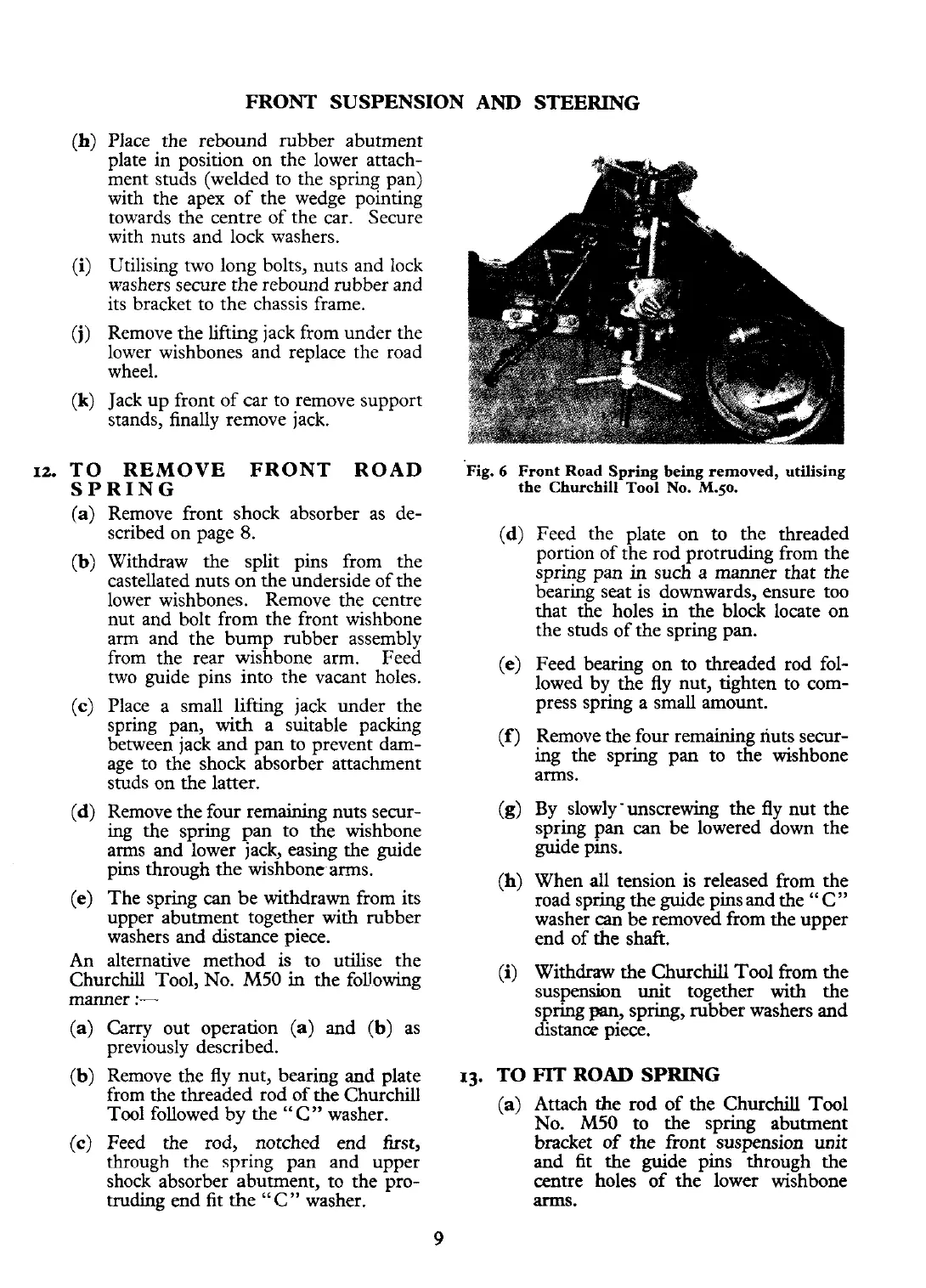

Fig.

6

Front Road Spring being removed, utilising

the Churchill Tool No.

M.50.

(d)

Feed the plate on to the threaded

portion of the rod protruding from the

spring pan

in

such a manner that the

bearing seat is downwards, ensure too

that the holes in the block locate on

the studs of the spring pan.

(e)

Feed bearing on to threaded rod fol-

lowed by the fly nut, tighten to com-

press spring a small amount.

(f)

Remove the four remaining nuts secur-

ing the spring pan to the wishbone

arms.

(g)

By slowly 'unscrewing the fly nut the

spring pan

can

be lowered down the

guide pins.

(h)

When all tension is released from the

road spring the guide pins and the

"

C

"

washer

can

be

removed from the upper

end of

the

shaft.

An alternative method is to utilise the

Churchill Tool, No.

M50

in

the following

(i)

Withdraw the Churchill Tool from the

manner

:-

suspension unit together with the

spring

pn,

spring, rubber washers and

(a)

Carry out operation

(a)

and

(b)

as

distance piece.

previously described.

(b)

Remove the fly nut, bearing and plate

13.

TO

FIT

ROAD SPRING

from the threaded rod of the Churchill

Tool followed by the "C" washer.

(a)

Attach

the

rod of the Churchill Tool

No.

M50

to the s~rinp: abutment

(c)

Feed the rod, notched end first, bracket of the front 'sus~ension unit

through the spring pan and upper and fit the guide pins through the

shock absorber abutment, to the pro- centre holes of the lower wishbone

truding end fit the "C" washer. arms.

Loading...

Loading...