Rg.

19

o

o

~.

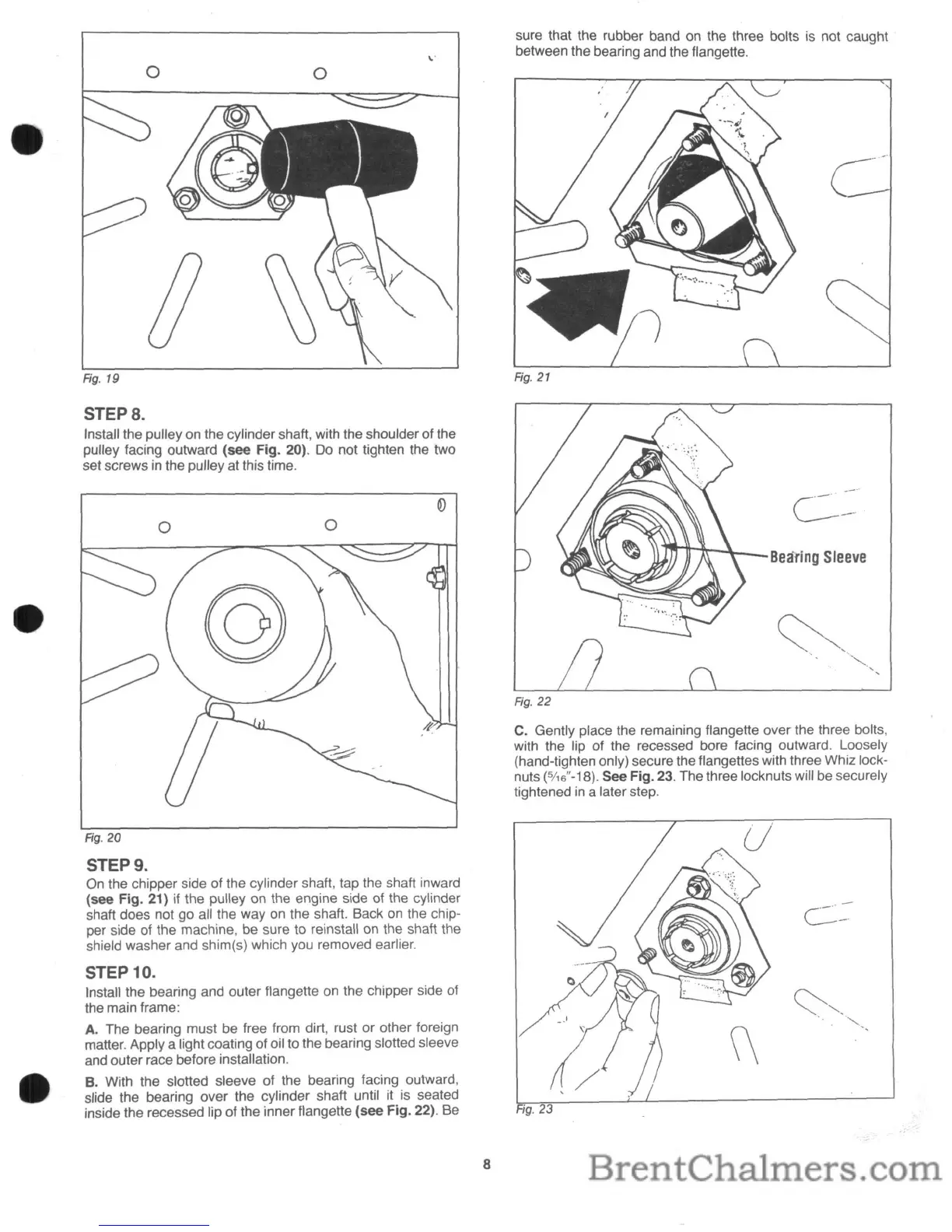

sure that the rubber band on the three bolts is not caught

between the bearing and the flangelle.

Fig.

21

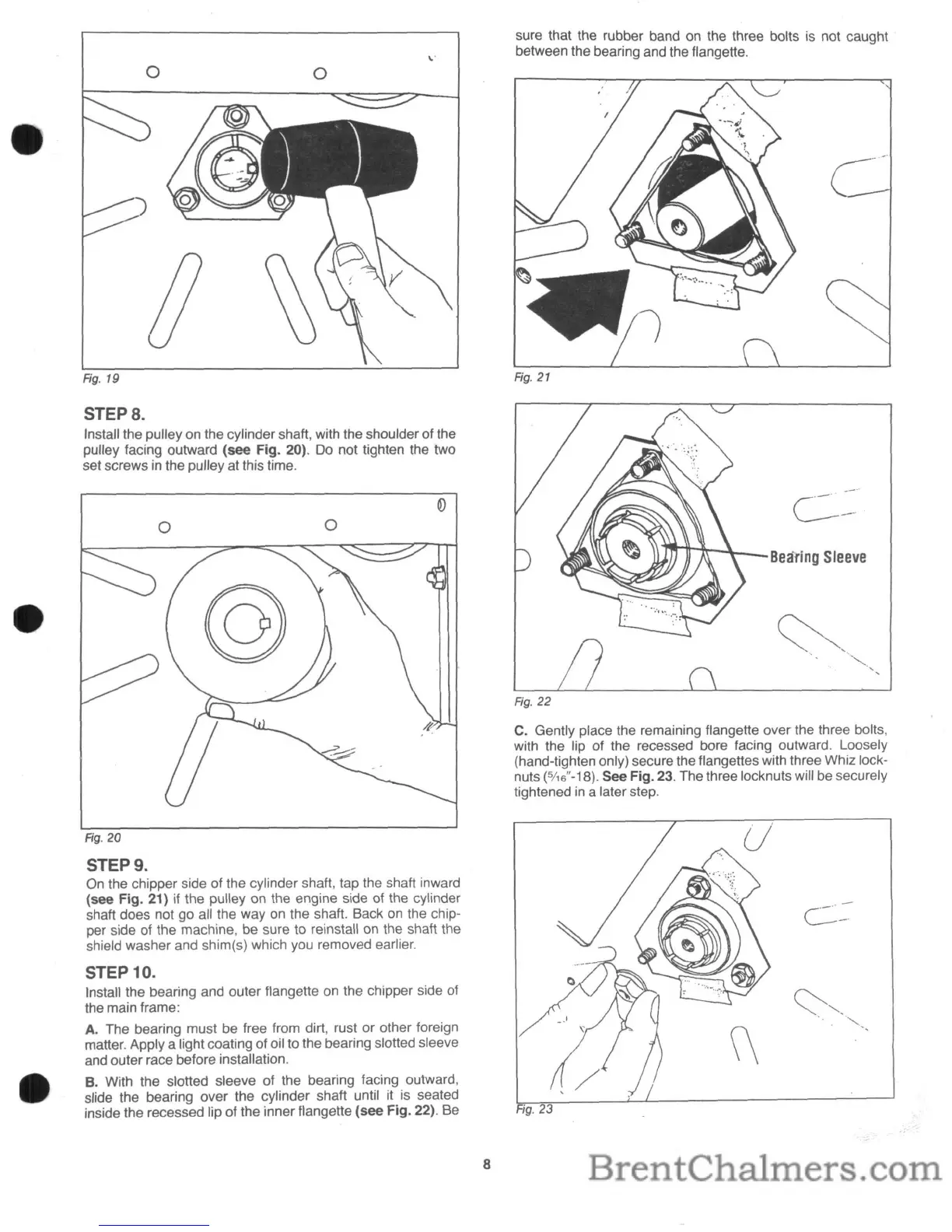

STEPS.

Install the pulley on the cylinder shaft, with the shoulder of the

pulley facing outward (see Fig. 20).

Do

not tighten the two

set screws

in

the pulley at this time.

c-·

Bearing

Sleeve

Fig. 22

C.

Gently place the remaining f1angelle over the three bolts,

with the lip of the recessed bore facing outward. Loosely

(hand-tighten only) secure the f1angettes with three Whiz lock-

nuts

(5116"-18).

See Fig.

23.

The three locknuts will be securely

tightened

in

a later step,

o

o

Fig. 20

STEP 9.

On

the chipper side of the cylinder shaft, tap the shaft inward

(see Fig. 21)

if

the pulley on the engine side of the cylinder

shaft does not go all the way on the shaft. Back

on

the chip-

per side of the machine, be sure to reinstall on the shaft the

shield washer and shim(s) which you removed earlier.

STEP 10.

Install the bearing and outer f1angette on the chipper side of

the main frame:

A. The bearing must be free from dirt, rust or other foreign

matter. Apply a light coating of oil to the bearing slotted sleeve

and outer race before installation.

B. With the slotted sleeve of the bearing facing outward,

slide the bearing over the cylinder shaft until it

is

seated

inside the recessed lip of the inner flangette (see Fig. 22). Be

C-

'-"-

-'

8

Loading...

Loading...