Do you have a question about the Troy-Bilt 634F-Bronco and is the answer not in the manual?

Symbol used to alert about potential hazards.

Key training steps and pre-operation checks for safe tiller operation.

Safety rules for operating the tiller and avoiding risks.

Location and meaning of safety and operational decals and symbols.

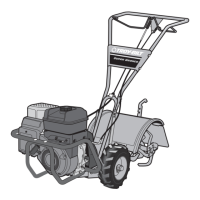

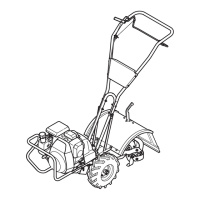

Overview, inspection, tools, and unpacking for tiller assembly.

Attaching the handlebar and installing the forward clutch cable.

Adjusting forward drive belt tension and installing reverse clutch cable.

Checking transmission oil, adding motor oil, and checking tire pressure.

Verifying tightness of all nuts and screws.

Overview of tiller controls and reference to engine controls.

How to engage and disengage wheel drive pins for modes.

Operation of clutch controls and handlebar/depth adjustments.

Introduction to operation and required break-in maintenance.

Essential checks and steps for starting the tiller.

Techniques for operating the tiller forward, reverse, and turning.

Setting tilling depth and choosing optimal wheel/tine speeds.

Best practices for operating the tiller effectively and avoiding issues.

Burying organic matter and safely tilling on slopes.

Safety precautions and step-by-step guide for loading/unloading.

Schedule of maintenance tasks and lubrication procedures.

Checking transmission oil, oil leaks, and tire pressure.

Procedures for draining transmission oil and servicing tines.

Procedure to check forward drive belt tension.

Details on obtaining and using replacement drive belts.

Checking and adjusting reverse drive belt tension.

Maintaining engine cleanliness and servicing the air cleaner.

Procedures for checking and changing engine oil.

Procedures for changing engine oil and servicing spark plugs.

Adjusting throttle lever and understanding governor settings.

Servicing the spark arrester screen.

Steps to prepare the tiller for off-season storage.

Diagnosing and resolving engine starting and running problems.

Troubleshooting drive system and poor tilling performance.

Illustrated breakdown and identification of tiller parts.

Details on what the warranty covers and excludes.

Procedures for locating dealers and obtaining service.

| Engine Type | 4-Cycle OHV |

|---|---|

| Number of Tines | 4 |

| Forward Speeds | 1 |

| Oil Capacity | 20 oz |

| Tilling Depth | 8 inches |

Loading...

Loading...