Section

5:

Tiller

And

Engine

Maintenance

There are a few very important steps that you can perform in order to get the best perfor-

mance and longest life from your tiller. These steps are: frequent engine oil changing, frequent

air cleaner element cleaning and replacing, keeping the engine cooling fins clean, lubricating

the tiller regularly, and keeping the belts adjusted properly.

You will be operating your tiller in a very dusty environment, often for extended time periods

at high temperatures. Proper maintenance is therefore very important.

A WARNING

Before performing any maintenance on your tiller, stop the engine,

allow it to cool, disconnect the spark plug wire and prevent it from

touching the spark plug, then remove the Engine Ignition key.

Failure to follow this instruction could result in personal injury or

property damage.

LUBRICATION

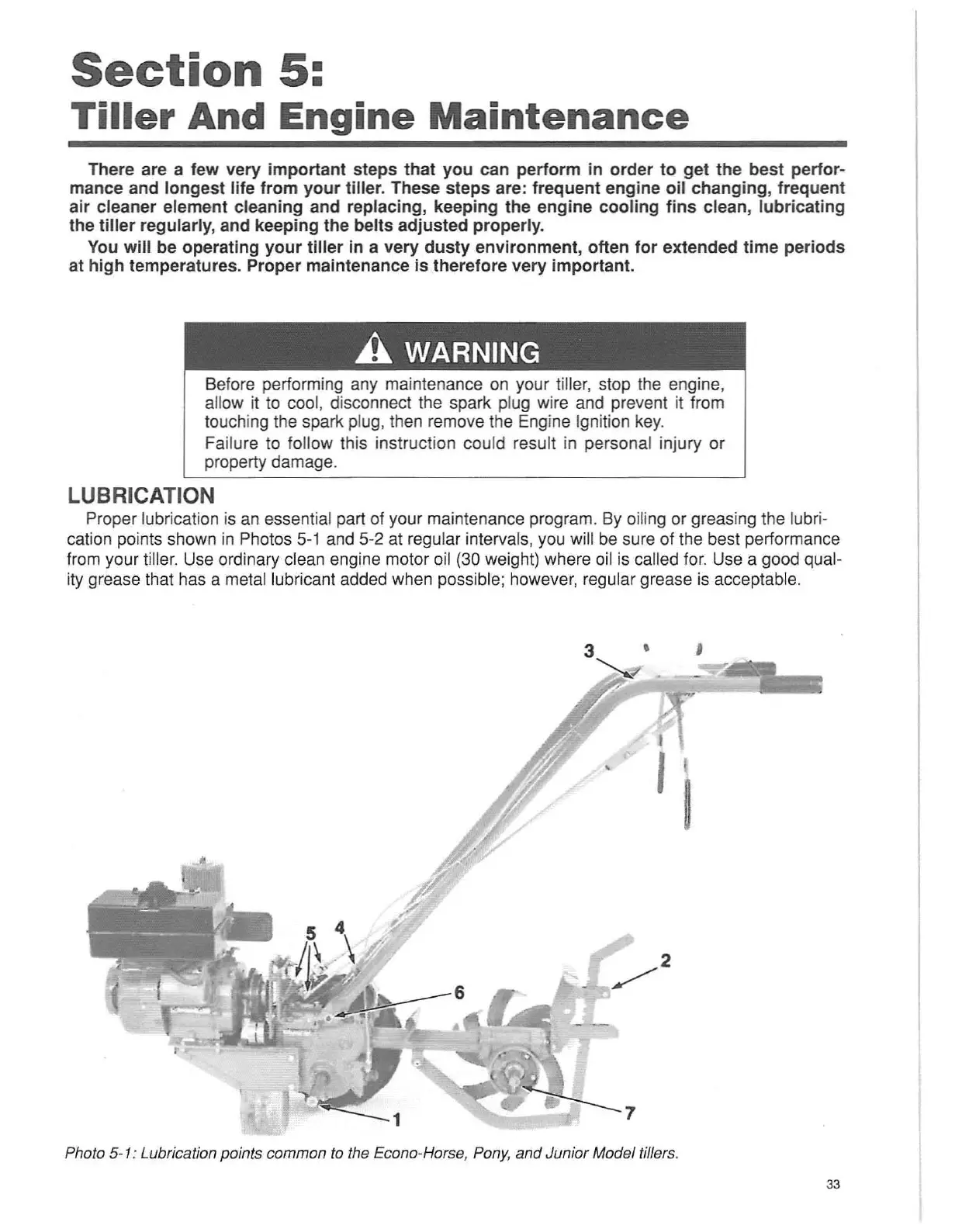

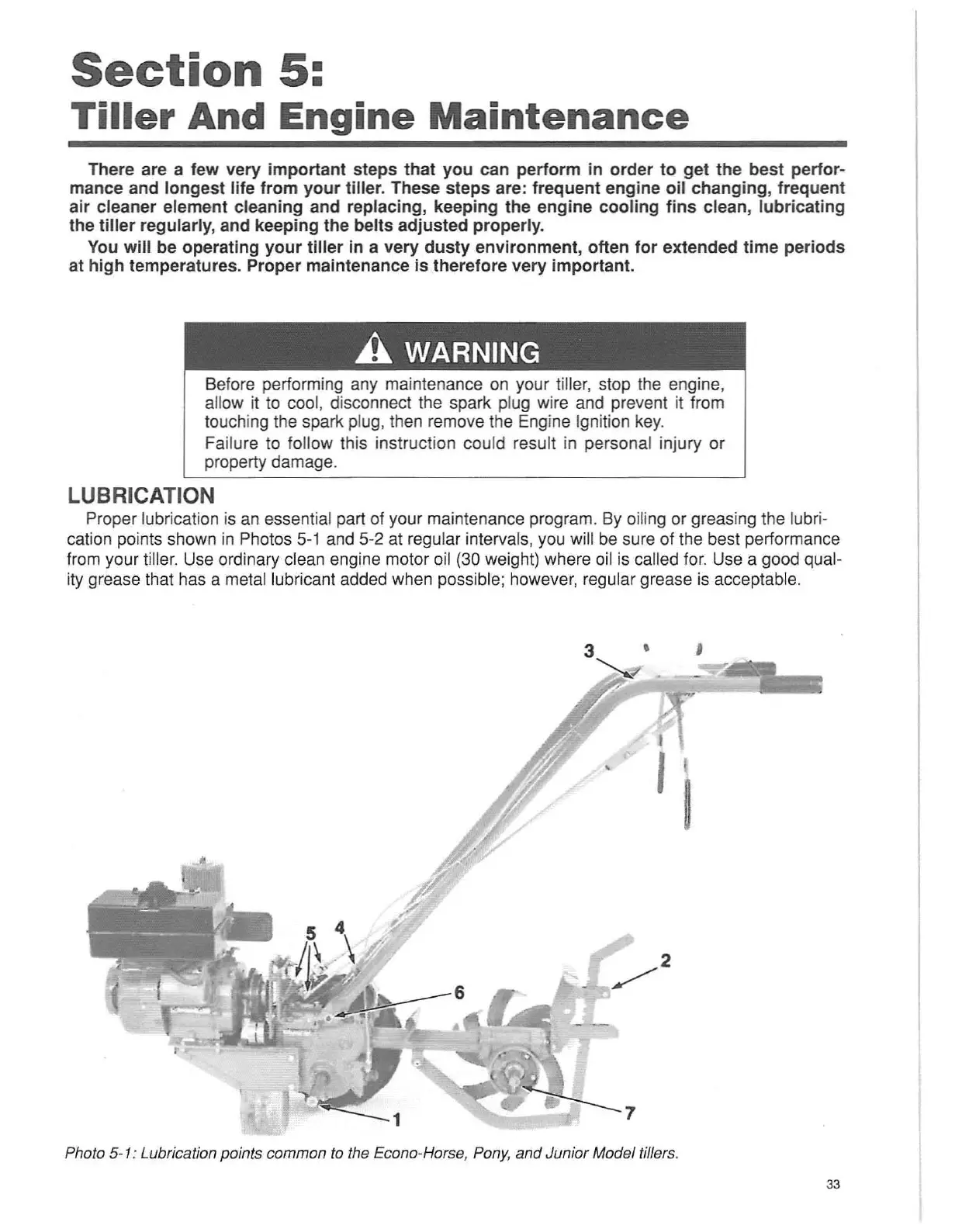

Proper lubrication is an essential part of your maintenance program. By oiling or greasing the lubri-

cation points shown in Photos 5-1 and 5-2 at regular intervals, you will be sure of the best performance

from your tiller. Use ordinary clean engine motor oil (30 weight) where oil is called for. Use a good qual-

ity grease that has a metal lubricant added when possible; however, regular grease is acceptable .

•

Photo 5-1: Lubrication points common to the Econo-Horse, Pony,

and

Junior Model tillers.

33

Loading...

Loading...