1. Remove one wheel , clean the wheel shaft,

and apply a thin coat of grease. Repeat at the

other end of the.wheel shaft.

2. Grease the back, front, and sides of the Depth

Regulator Lever.

3. Oil the entire length of the Engine Throttle

cable (all models) and the Wheel Gear cable (ex-

cept Junior ModeL) Just apply oil to the outside

of the cables, allow it to work its way inside, and

wipe off the excess oil.

4. Oil the th reads on the

Handlebar

Height

Adjustment Handle.

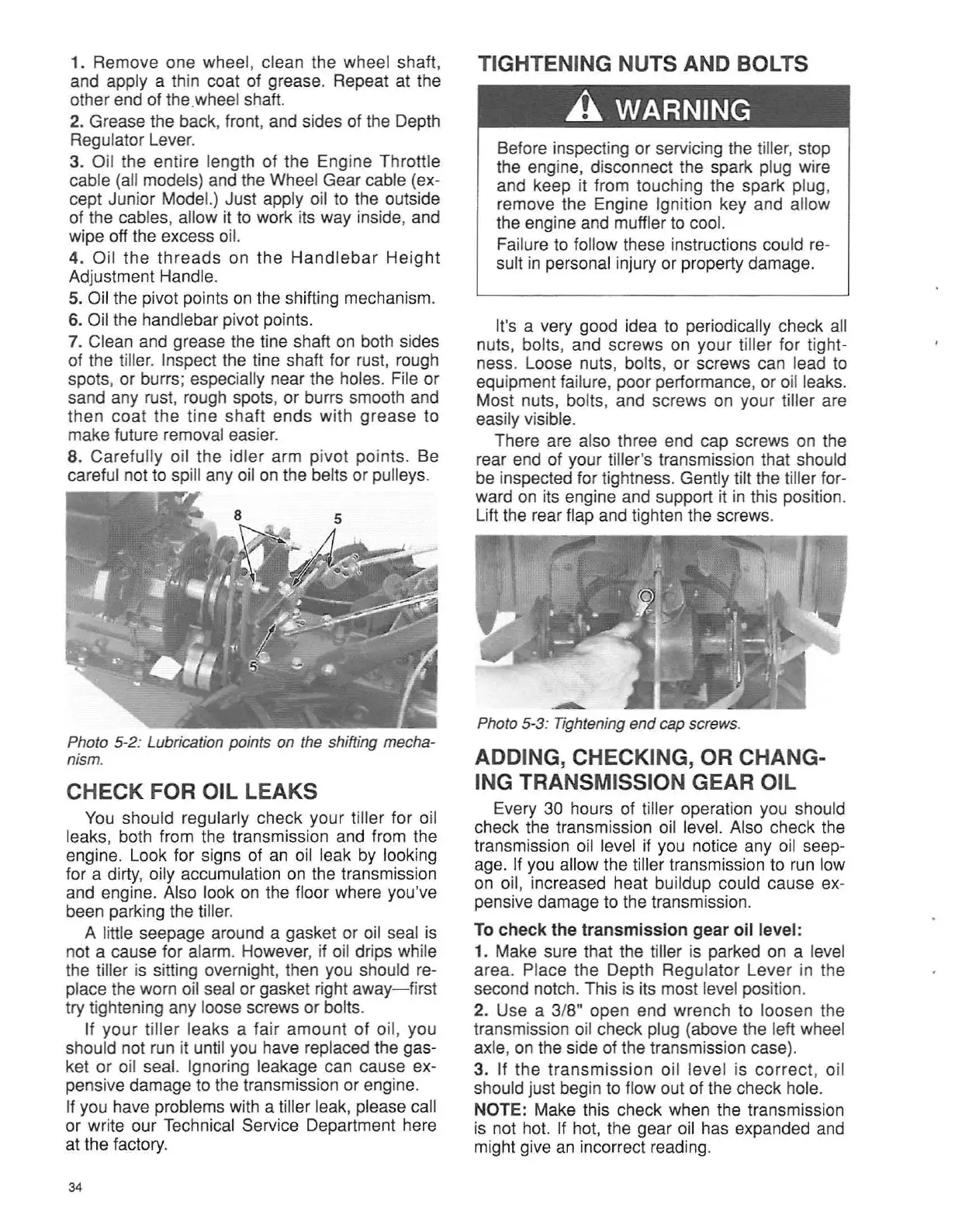

5. Oil the pivot points on the shifting mechanism.

6. Oil the handlebar pivot points.

7. Clean and grease the tine shaft on both sides

of the tiller. Inspect the tine shaft for rust, rough

spots, or burrs; especially near the holes. File or

sand any rust, rough spots, or burrs smooth and

then coat the tine shaft ends with grease to

make future removal easier.

8.

Car

efully oil the idler arm pivot points. Be

careful not to spill any oil on the belts or pulleys.

Photo 5-2: Lubrication points on the shifting mecha-

nism.

CHECK FOR OIL LEAKS

You should regularly check your tille r for oil

leaks, both from the transmission and from the

engine. Look for signs of an oil leak by looking

for a dirty, oily accumulation on the transmission

and engine. Also look on the floor where you've

been parking the tiller.

A little seepage around a gasket or oil seal is

not a cause for alarm. However, if oil drips while

the tiller is sitting overnight, then you should

re-

place the worn oil seal or gasket right away- first

try tightening any loose screws or bolts.

If your tiller leaks a fair amount of oil, you

should not run it until you have replaced the gas-

ket or oil seal. Ignoring leakage can cause ex-

pensive damage to the transmission or engine.

If you have problems with a tiller leak, please call

or write our Technical Service Department here

at the factory.

34

TIGHTENING NUTS AND BOLTS

A WARNING

Before inspecting or servicing the tiller, stop

the engine, disconnect the spark plug wire

and keep it from touching the spark plug,

remove the Engine Ignition key and allow

the engine and muffler to cool.

Failure to follow these instructions could re-

sult in personal injury or property damage.

It's a very good idea to periodically check all

nuts, bolts, and screws on your tiller for tight-

ness. Loose nuts, bolts, or screws can lead to

equipment failure, poor performance, or oil leaks.

Most nuts, bolts, and screws on your tiller are

easily visible.

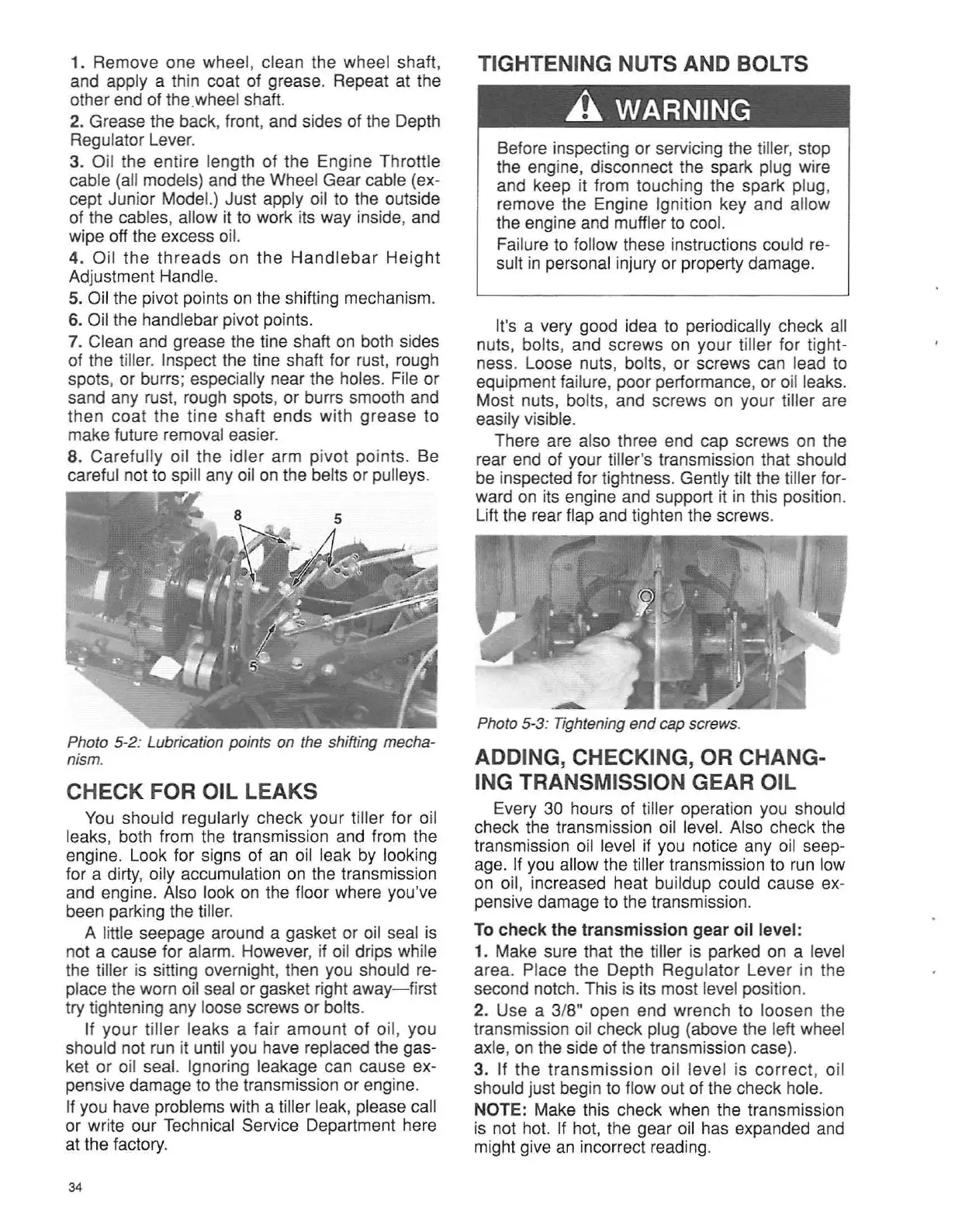

There are also three end cap screws on the

rear end of your tiller's transmission that should

be inspected for tightness. Gently tilt the tiller for-

ward on its engine and support it in this position.

Lift the rear flap and tighten the screws.

---

Photo 5-3: Tightening end cap screws.

ADDING, CHECKING, OR CHANG-

ING TRANSMISSION GEAR OIL

Every 30 hours of tiller operation you should

check the transmission oil level. Also check the

transmission oil level if you notice any oil seep-

age. If you allow the tiller transmission to run low

on oil, increased heat buildup could cause ex-

pensive damage to the transmission.

To

check

the

transm

ission

gear oil level:

1. Make sure that the tiller is parked on a level

area. Place the Depth Regulator Lever in the

second notch. This is its most level position.

2. Use a 3/8" open end wrench to loosen the

transmission oil check plug (above the left wheel

axle, on the side of the transmission case).

3.

If the transmission oil level is

cor

rect, oil

should just begin to flow out of the check hole.

NOTE: Make this check when the transmission

is not hot. If hot, the gear oil has expanded and

might give an incorrect reading.

Loading...

Loading...