user manual

FLEX ARRAY

FLEX ARRAY user manual

Page 35

Rigging Components

The Flex Array „A‟ mode, or horizontal, rigging system includes all the necessary hardware

to enable vertical suspension of TFA-600 series cabinets from a single rigging point and

using only a single motor rated at 1 tonne.

The FB-600 adjustable lift point flybar supports the entire weight of the loudspeaker cluster

by engaging into the steel flygear rebated into the short sides of the loudspeaker enclosures,

whose integrated drop links locate into the flyware of the cabinet directly underneath to form

the pivot points about which cabinets are angled vertically. The drop links are secured in

position with captive ball-lock pins that stow into cabinet recesses for transportation. The

cabinet‟s rear drop link pivots down to engage in the clevis connection plate of the cabinet

below in several positions, which permits a range of inter-cabinet angle adjustment, in 2°

increments, from 0° to 16°.

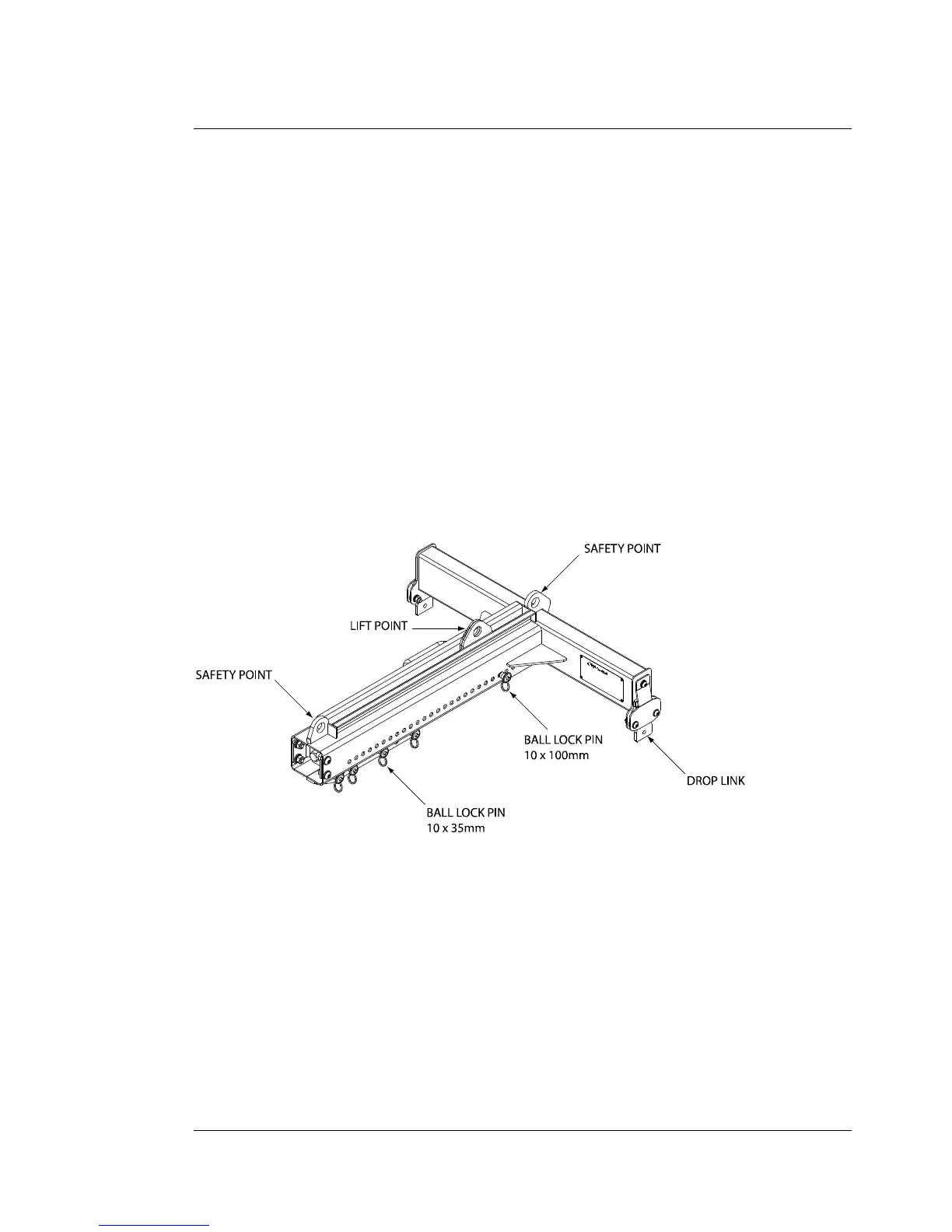

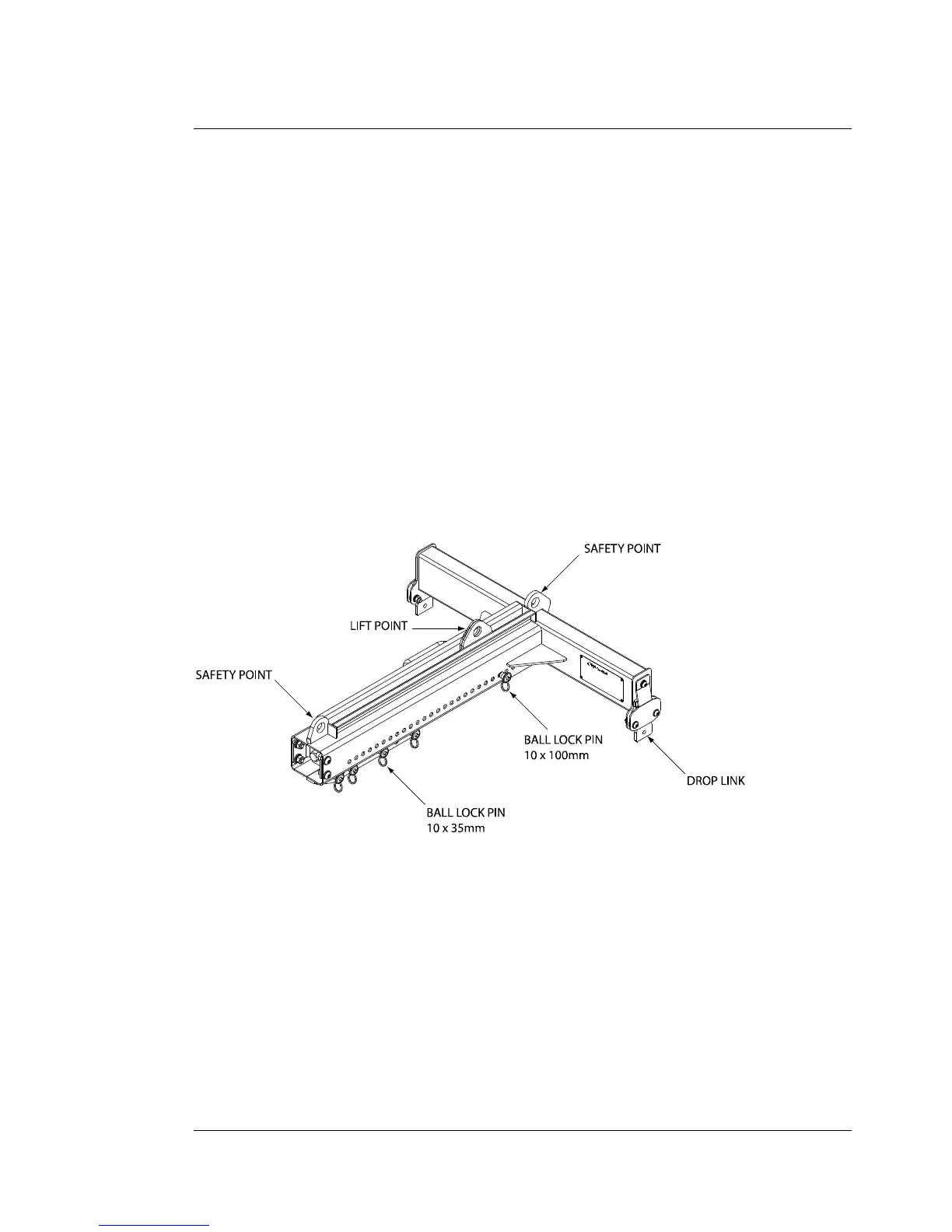

FB-600 Adjustable Lift Point Flybar

The FB-600 is a T-shaped flybar that enables the suspension of TFA-600H mid/high and TFA-

600L low frequency loudspeakers up to an SWL of 700kg, and is used for the creation of

flown Flex Array line arrays. The frame is constructed from rectangular box steel section with

a unique formed rear spine containing a channel in which the lift point is located.

The movable lift point can be traversed along the length of the spine from front to rear by

means of a screw thread, which is turned by a 22mm (7/8”) socket driven by a speed brace or

hand held electric drill. The screw is located in polymer-sealed bearings requiring no

maintenance under normal operating conditions, and is designed to last the lifetime of the

product.

Loading...

Loading...