MODBUS RTU Transmission Mode

When the instrument uses RTU (Remote Terminal Unit) mode for MODBUS serial communication, each

8-bit byte of information contains two 4-bit hexadecimal characters

. The main advantages of this

mode are greater character density and better data throughput than the ASCII mode with the same

baud rate

. Each message must be transmitted as a continuous string.

The format of each byte in RTU mode (11 bits):

Coding system: 8-bit binary

Each 8-bit byte in a message contains two 4-bit hexadecimal characters (0-9, A-F)

Bits in each byte: 1 starting bit

8 data bits, the first minimum valid bits without parity check bits

2 stop bits

Baud rate: 9600 BPS

How characters are transmitted serially:

Each character or byte is sent in this order (from left to right) the least significant bit (LSB)... Maximum

Significant Bit (MSB)

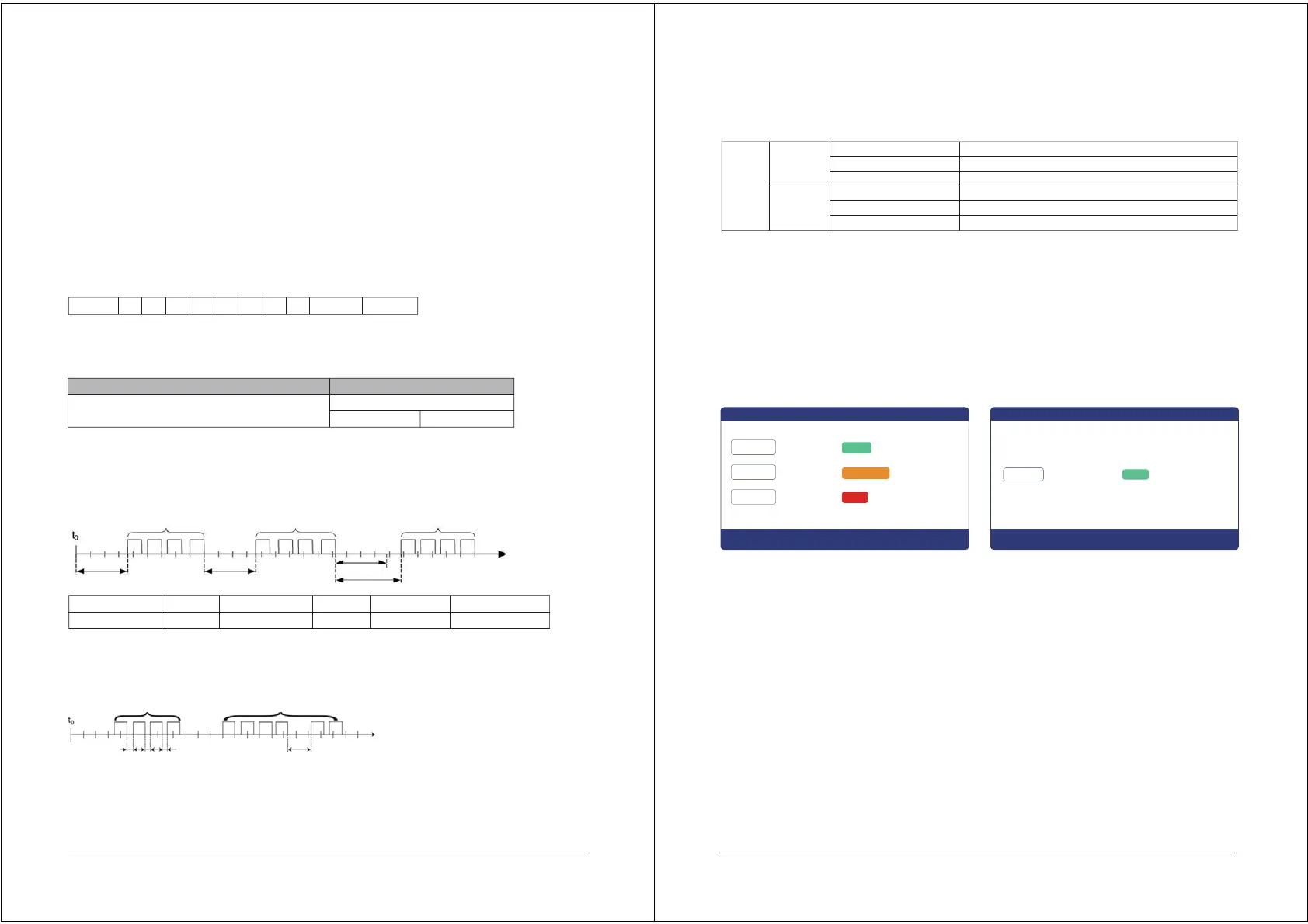

Figure 3: RTU pattern bit sequence

Check Domain Structure: Cyclic Redundancy Check (CRC16)

Structure description:

Figure 4: RTU information structure

The maximum frame size of MODBUS is 256 bytes

MODBUS RTU Information Frame

In RTU mode, message frames are distinguished by idle intervals of at least 3.5 character times, which

are called t3.5 in subsequent sections.

Figure 5: RTU message frame

The entire message frame must be sent in a continuous character stream.

When the pause time interval between two characters exceeds 1.5 characters, the information frame

is considered incomplete and the receiver does not receive the information frame.

MODBUS RTU CRC Check

The RTU mode contains an error-detection domain based on a cyclic redundancy check (CRC)

algorithm that performs on all message contents. The CRC domain checks the contents of the entire

message and performs this check regardless of whether the message has a random parity check. The

CRC domain contains a 16-bit value consisting of two 8-bit bytes. CRC16 check is adopted..Low bytes

precede, high bytes precede.

13

Start bit 1 2 3 4 5 6 7 8 Stop bit Stop bit

Slave Instrument

Address

Function Code

1 byte

Data

0…252 byte

CRC

2 byte

CRC Low byte CRCHigh byte

Starting

≥3.5 characters

Address

8 bit

Function code

8 bit

Data

Nx8 bit

CRC check

16 bit

End

≥3.5 characters

At least 3.5 characters At least 3.5 characters

Frame 1 Frame 2 Frame 3

4.5 characters

3.5 characters

Frame 1 normal

≤1.5 characters >1.5 characters

Frame 2 failure

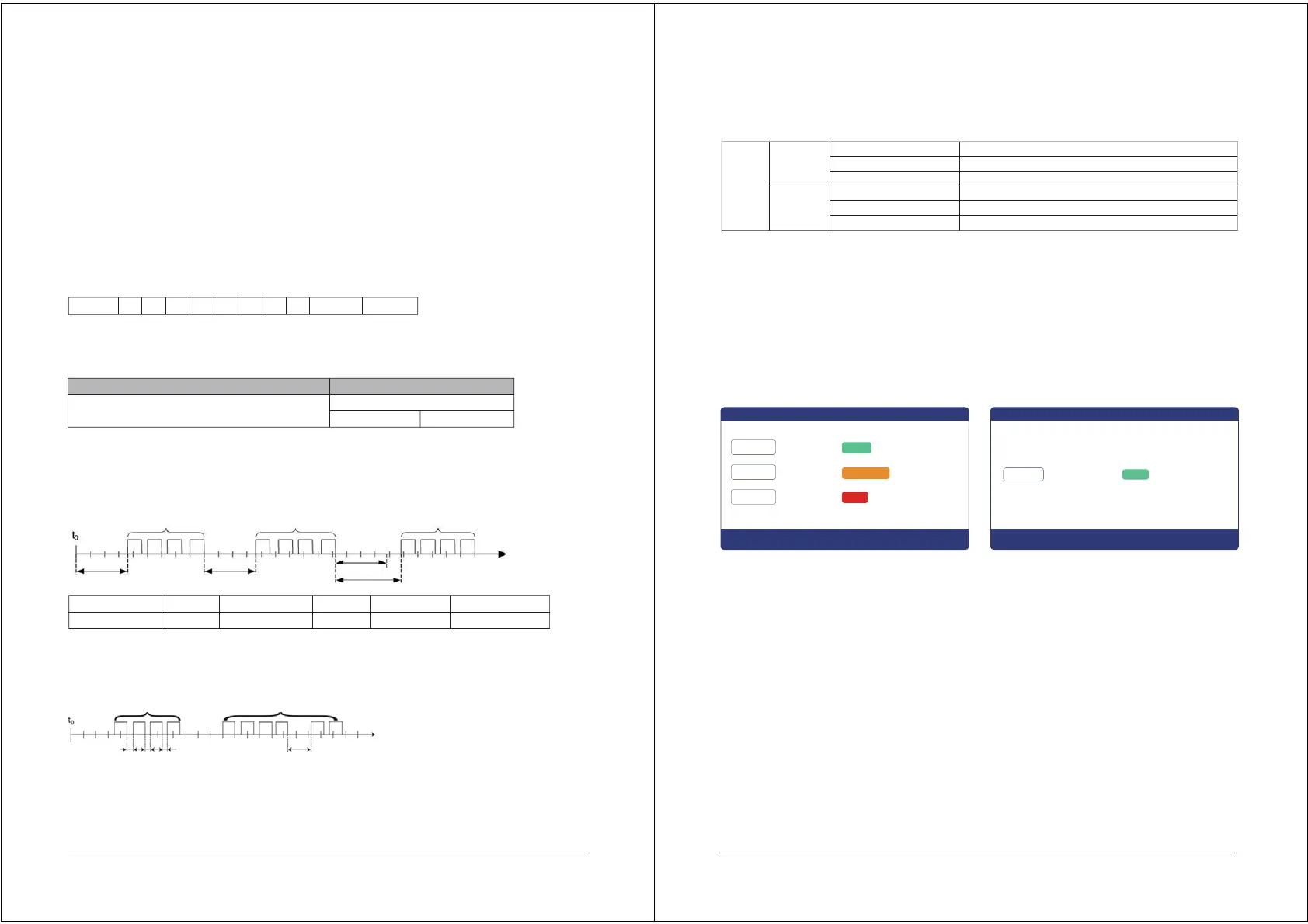

USA:7.00,4.01,10.01

NIST:6.86,4.01,9.18

ORP Standard Sulution

Field Calibration

Offset Adjustment

Slope Adjustment

Standard

Calibration

Field

Calibration

Calibration

Automatic identification, calibrate 7.00 first

Automatic identification, calibrate 6.86 first

235mV(Default)

Calibration of Standard Solution

Select the Standard Solution Calibration, a total of two groups: USA: 7.00, 4.01, 10.01 and NIST:

6.86, 4.01, 9.18. After the selection is completed, press the [ENT] button to confirm and enter the

standard sulution calibration mode.

If the instrument has been calibrated, the screen shows the calibration status and then press theս

ENTվ key again to enter the re-calibration if you need re-calibration.

If the monitor prompts you to enter the calibration security password, press theսӞվ key or սӜվkey to set the

calibration security password, and then press the սENTվkey to confirm the calibration security password.

PH Calibration: After entering the calibration mode, the instrument displays as shown above.

The instrument automatically identifies the standard liquid, first calibrates the midpoint (example

7.00pH), then calibrates 4.01pH or 10.01pH. The corresponding mV value will be displayed on the

left side of the screen.

After the calibration is completed, the offset and slope will be displayed on the right side of the

screen.

If only two points of calibration are needed, after two points of calibration, press the սMenuվ

button to exit directly.

During the calibration process, Error prompt appears on the screen when the standard liquid is

wrong.

Calibration results: The slope of glass electrode (> 0.90) is qualified, and that of metal antimony

electrode (> 0.80) is qualified.

Calibration

Press [MENU] to enter the setting mode and select the calibration

PH Calibration ORP Calibration

10

7.00

4.01

10.01

-5 mV

170 mV

-25 mV

0.98

Done

Calibrating

Error

offset:

Slope:

pH / ORP

pH / ORP

235

0.98Done Slope:

228 mV

Loading...

Loading...