TFP802

Page 2 of 6

Technical

Data

Approvals

The natural finish, chrome plated, and

lead coated bronze, as well as stain-

less steel Type D3 PROTECTOSPRAY

Nozzles are UL and C-UL Listed, as

well as FM and EAC Approved.

Maximum Working Pressure

175 psi (12,1 bar)

Also refer to Figure 2, Note 2

Discharge Coefficient

Refer to Table A

Spray Angles

Refer to Table B

Finish and Material

Refer to Table E

Thread Connection

1/2 inch NPT

Physical Characteristics

(Bronze)

Frame . . . . . . . . . . . . . . . . . . . . . . . . . . . .Bronze

Deflector . . . . . . . . . . . . . . . . . . . . . . . . . .Bronze

Splitter . . . . . . . . . . . . . . . . . . . . . . . . . . . .Bronze

Pin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Bronze

Physical Characteristics

(Stainless Steel)

Frame ............ASTM A-743 Grade CF-8M

(equiv. Type 316 S.S.)

Deflector . . . . . . . . . . . . . . . . . . . . Type 316 S.S.

Splitter . . . . . . . . . . . . . . . . . . . . . . Type 316 S.S.

Pin ......................... Type 316 S.S.

Design

Criteria

Nozzle Placement. Where direct

impingement of water spray onto all

of the protected surface is required by

the authority having jurisdiction, the

nozzles are to be spaced and directed

so that their spray patterns will com-

pletely cover the plane-of-protection

with the minimum required average

density; however, it is recommended

that indoor nozzle spacing be 12 ft.

(3,7 m) or less and that outdoor nozzle

spacing be 10 ft. (3,0 m) or less. Where

rundown or slippage is planned, such

as, exposure protection of vessels per

NFPA 15, the above rec ommended

indoor and outdoor spac ings also

apply.

When used for protecting the surfaces

of a vessel, for example, the nozzles

are positioned normal to and approxi-

mately 2 ft. (0,6 m) from the surface.

This approach, in conjunction with

a properly selected spray angle, will

tend to make more effective use of the

spray as well as help minimize the dis-

turbance effects of wind/draft condi-

tions on the water spray patterns.

Spray Patterns. The Design Spray

Profiles for the nozzle spray angles of

65 to 180 degrees are shown in Figure

2 and apply to discharge pressures of

20 to 60 psi (1,4 to 4,1 bar). Discharge

pressures in excess of 60 psi (4,1 bar)

will result in a decrease in coverage

area since the spray patterns tend to

draw inwards at higher pressures. Refer

inquiries on higher discharge pressures

to the Technical Services Department.

The maximum axial distances between

the nozzle tip and plane-of-protection,

for exposure protection, are given in

Table C and D. When the axial dis-

tance from the nozzle tip to the plane-

of-protection is 2 ft. (0,6 m) or less,

the Design Spray Profile is the same

as the nominal spray angles of 65 thru

140 degrees.

Main Pipeline Strainers. Main pipe-

line strainers per NFPA 15 are required

for systems utilizing nozzles with a flow

path less than 3/8 in. (9,5 mm) diam-

eter, i.e., No. 16 thru No. 24 (Ref. Table

A), and for any system where the water

is likely to contain obstructive material.

Installation

The TYCO Type D3 Protectospray

Nozzles must be installed in accor-

dance with this section.

General Instructions

A leak-tight 1/2 inch NPT nozzle joint

should be obtained by applying a

minimum to maximum torque of 7 to 14

ft.-lbs. (9,5 to 19,0 Nm). Higher levels

of torque may cause impairment of the

nozzle.

Step 1. With pipe-thread sealant

applied to the pipe threads, hand

tighten the nozzle into the nozzle fitting.

Step 2. Tighten the nozzle into the

nozzle fitting using only the W-Type 11

Sprinkler Wrench (Figure 3). With ref-

erence to Figure 1, apply the W-Type

11 Sprinkler Wrench to the wrenching

area.

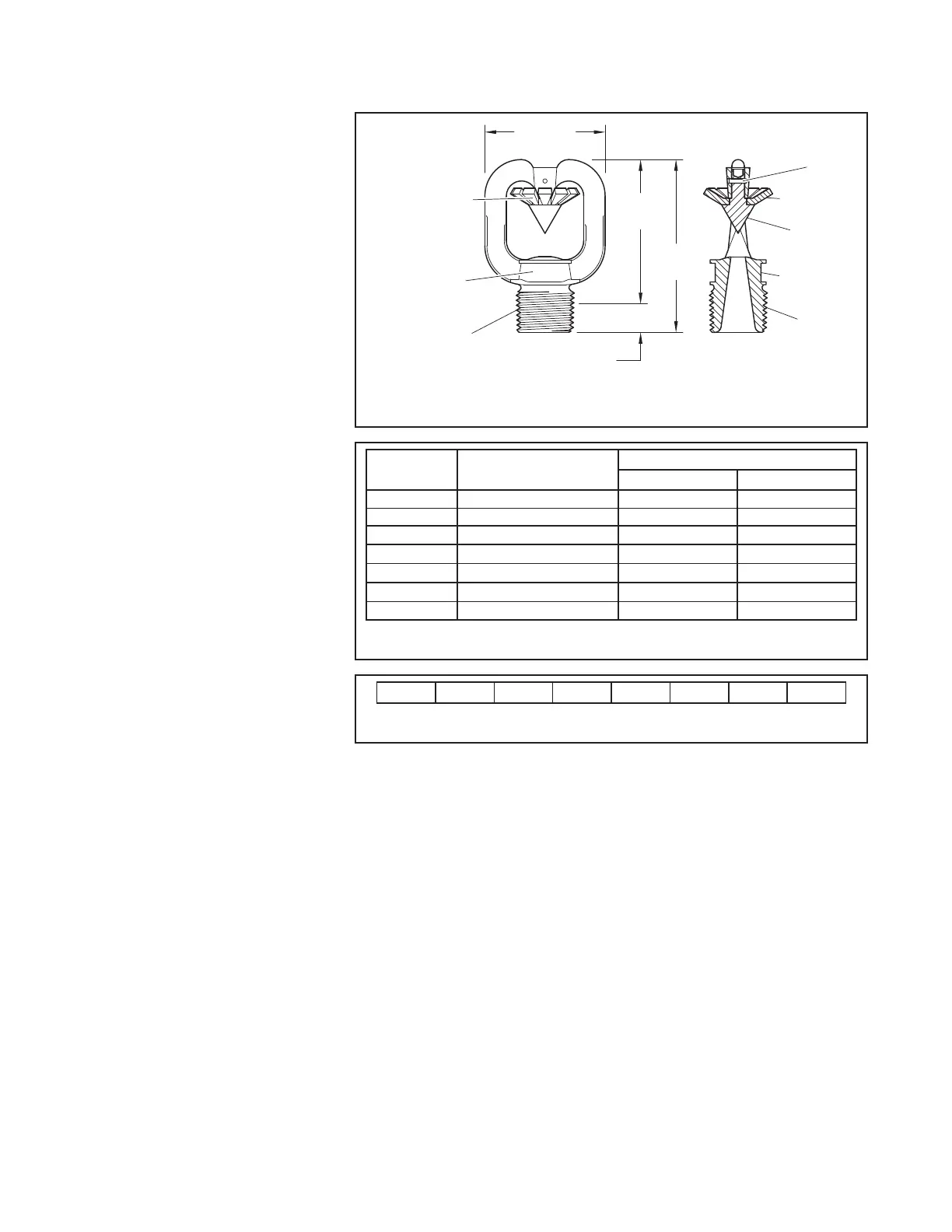

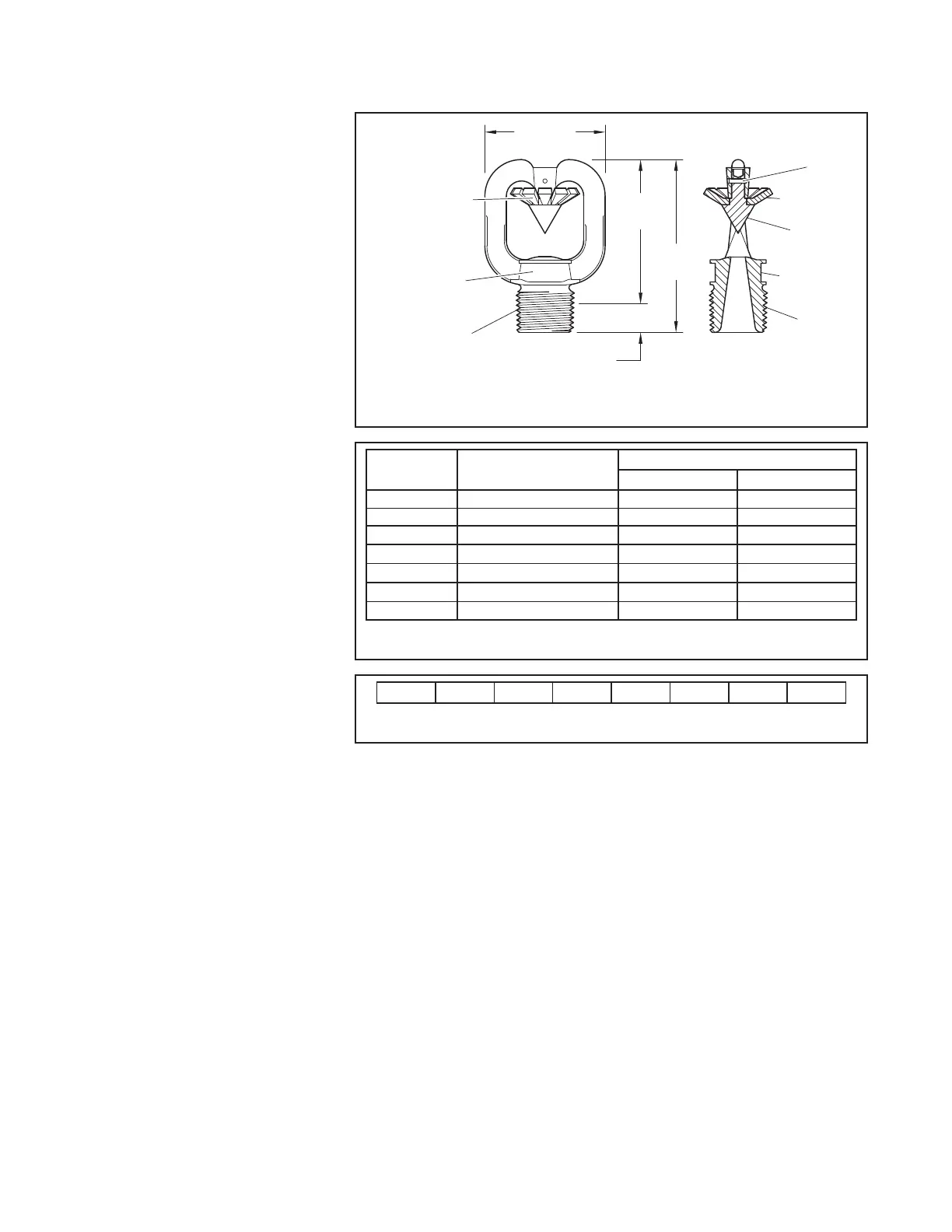

ORIFICE

SIZE

MINIMUM

DIAMETER

K-FACTOR

GPM/psi

½

LPM/bar

½

NO. 16 0.203” (5,16 mm) 1.2 17, 3

NO. 18 0.250” (6,35 mm) 1.8 25,9

NO. 21 0. 281” ( 7,14 m m ) 2.3 33,1

NO. 24 0.328” (8,33 mm) 3.0 43,2

NO. 28 0.375” (9,53 mm) 4.1 59,0

NO. 32 0.438” (11,13 mm) 5.6 80,6

NO. 34 0.500” (12,70 mm) 7. 2 103,7

65° 80° 95° 110° 125° 140° 160° 180°

AREA

2-1/2"

(63,5 mm)

(44,5 mm)

2-1/16"

(52,4 mm)

1/2" NPT

ORIFICE SIZE

STAMPED ON

WRENCHING

AREA

PIN

DEFLECTOR

SPLITTER

FRAME

7/16" (11,1 mm)

SPRAY ANGLE

OF DISCHARGE)

STAMPED ON

DEFLECTOR

FIGURE 1

TYPE D3 PROTECTOSPRAY NOZZLES

NOMINAL DIMENSIONS

TABLE A

SELECTION OF ORIFICE SIZES

TABLE B

SELECTION OF SPRAY ANGLES

Loading...

Loading...