TFP802

Page 3 of 6

Care must be exercised to avoid

damage to the nozzles before, during,

and after installation. Nozzles damaged

by dropping, striking, wrench twist/slip-

page, or the like, must be replaced.

Frequent visual inspections are rec-

ommended to be initially performed

for nozzles installed in potentially cor-

rosive atmospheres to verify the integ-

rity of the materials of construction and

finish as they may be affected by the

corrosive conditions present for a given

installation. Thereafter, annual inspec-

tions per NFPA 25 are required.

Water spray fixed systems for fire pro-

tection service require regularly sched-

uled care and maintenance by trained

personnel. In addition to inspect-

ing nozzles for proper spray perfor-

mance during water flow trip tests of

the system, it is recommended that

nozzles be periodically inspected

for broken or missing parts (includ-

ing blow-off plugs where applicable),

loading/obstructions, or other evidence

of impaired protection. The inspec-

tions should be scheduled weekly or

as frequently as may be necessary,

and corrective action must be taken

to ensure that the nozzles will perform

as intended in the event of a fire.

For installations subject to freezing

and where blow-off plugs have been

installed, a periodic inspection must be

performed for evidence of ice build-up

from trapped condensate which could

affect the proper release of the blow-

off plugs.

The owner is responsible for the inspec-

tion, testing, and maintenance of their

fire protection system and devices in

compliance with this document, as well

as with the applicable standards of the

NATIONAL FIRE PROTECTION ASSO-

CIATION (e.g., NFPA 25), in addition to

the standards of any other authorities

having jurisdiction. Contact the install-

ing contractor or product manufacturer

with any questions.

Water spray fixed systems are rec-

ommended to be inspected, tested,

and maintained by a qualified Inspec-

tion Service in accordance with local

requirements and/or national codes.

Care and

Maintenance

The TYCO

Type D3 PROTECTOSPRAY

Nozzles must be maintained and ser-

viced in accordance with this section.

Before closing a fire protection system

main control valve for maintenance

work on the fire protection system that

it controls, permission to shut down the

affected fire protection system must be

obtained from the proper authorities

and all personnel who may be affected

by this action must be notified.

Type D3 PROTECTOSPRAY Nozzles

must never be painted, plated, coated

or altered in any way after leaving the

factory; otherwise, the spray perfor-

mance may be impaired.

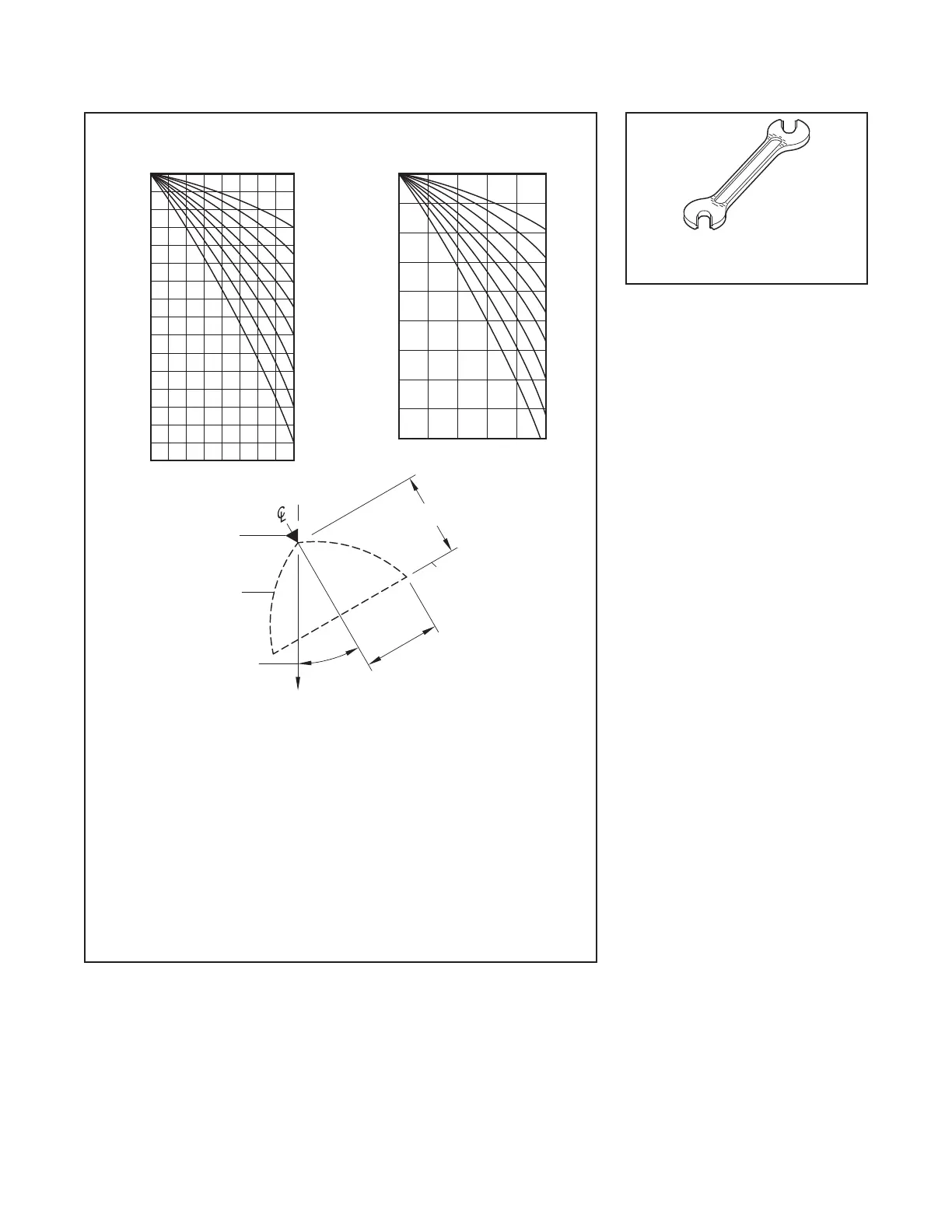

AXIAL DISTANCE

NOZZLE

PLANE OF

PROTECTION

PROFILE

SPRAY

(ORIENTATION)

FIXED ANGLE

GRAVITY

The shapes of the Design Spray Proles remain essentially unchanged over the

maximum Axial Distances shown in Tables C and D.

Refer to the authority having jurisdiction for their minimum required residual pressures.

3.

Design data applies to a residual (owing) pressure range at the nozzle inlet of 20 to

60 psi (1,4 to 4,1 bar). For pressures up to 175 psi (12,1 bar) consult Johnson

Controls Technical Services.

Design data obtained from tests in still air.

2.

1.

DISTANCE

RADIAL

For axial distances of 2 feet (0,6 meters) and less and for nozzle spray angles of 65°

to 140°, the Design Spray Prole is the same as the nominal spray angle.

4.

The maximum Axial Distances shown in Tables C and D are based on exposure

5.

95°

65°

80°

0

14

12

10

8

6

4

2

0

2 4 6 8

NOZZLE CENTERLINE, FEET

AXIAL DISTANCE FROM NOZZLE, FEET

80°

95°

0,5

0

1,0

1,5

2,0

2,5

3,0

3,5

4,0

4,5

0 0,5 1,0 1,5 2,0 2,5

NOZZLE CENTERLINE, METERS

RADIAL DISTANCE FROM

AXIAL DISTANCE FROM NOZZLE, METERS

FIGURE 2

WATER DISTRIBUTION DESIGN DATA

FIGURE 3

W-T YP E 11

SPRINKLER WRENCH

Loading...

Loading...