Installation info

18

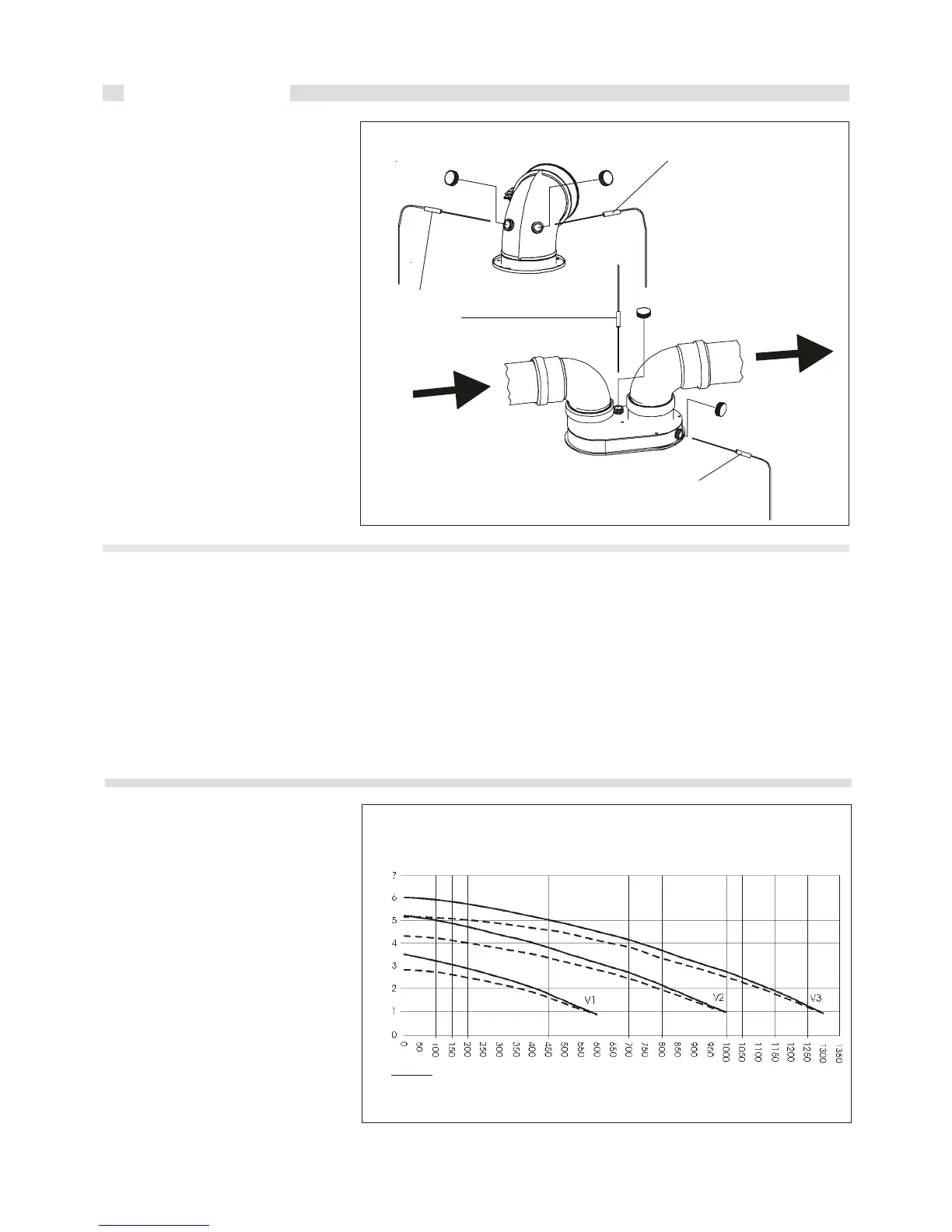

fig. 17

1

2

fig. 15

1

2

TSC0210C

ADA0160C

Analyser

probes

Analyser

probes

Smokes

Air

2.2.9 - ON SITE COMBUSTION

EFFICIENCY MEASUREMENT

Coaxial ducts

(Type A accessories)

To determine combustion efficiency the

following measurements must be made:

- the combustion air temperature measured

in hole 2 (see fig. 15).

- the flue gas temperature and CO2 %

measured in hole 1 (see fig. 15).

Make these measurements with the

boiler running in a steady state

condition.

(Type B accessories)

Separate ducts

To determine combustion efficiency the

following measurements must be made:

- the combustion air temperature measured

in hole 2 (see fig. 15).

- the flue gas temperature and CO2 %

measured in hole 1 (see fig. 15).

Make these measurements with the

boiler running in a steady state

condition.

Analyser

probes

2.2.10 - GAS SUPPLY LINE

The gas supply line must have a diameter

equal or larger than the one used in the boiler.

Comply with the applicable local installation

requirements which shall be considered as

having been incorporated in full in this

manual.

Before opening the internal gas supply

system; i.e. before connecting the gas

meter, all seals must be checked.

If any part of the system is concealed the

seals must be checked before the pipes

are covered.

The seal test must be conducted using air

or nitrogen at a pressure of at least 100

mbar.

The commissioning of the boiler also

includes the following operations and

checks:

- Opening of the gas gate valve and venting

of the air contained in the piping and boiler,

proceding appliance by appliance.

- Check, with the gate valve of all the

appliance

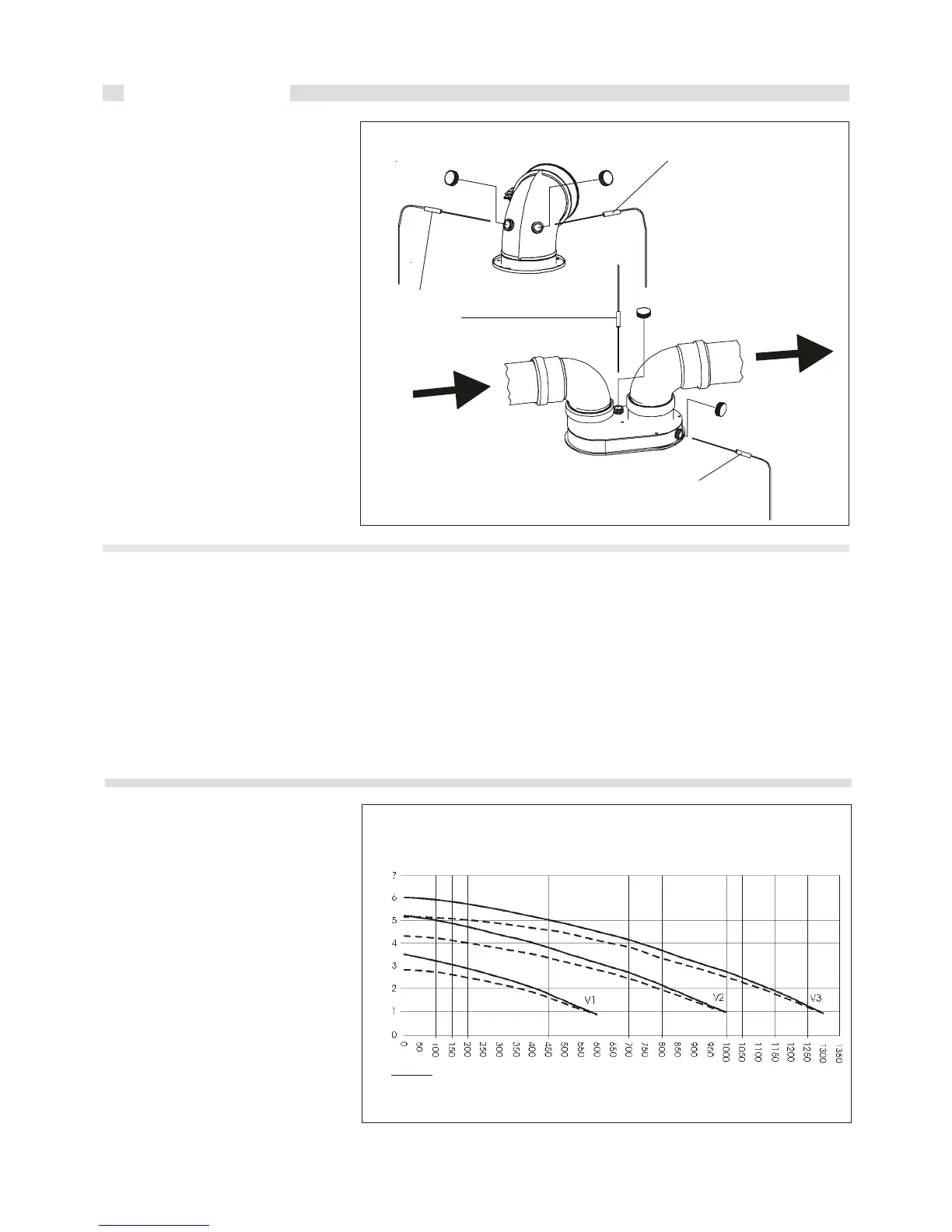

DIAGRAM FLOW RATE/MANOMETRIC HEAD AVAILABLE FOR C.H. SYSTEM

= By-Pass CLOSED

= By-Pass OPEN

..............

Flow rate l/h (Q)

Available Manometric Head m c.e.

2.2.11 - HYDRAULIC CONNECTIONS

Before installing the boiler we recommend

that the system be cleaned to remove any

impurities which could originate from

components and which could risk damaging

the circulating pump and heat exchanger.

HEATING

The heating flow and return must be

connected to the relevant ¾” connections

of the boiler M and R (see fig. 5).

When determining the size of the heating

circuit pipes it is essential to bear in mind

the pressure losses induced by radiators,

any thermostatic valves, radiator cut-off

valves and the configuration of the system.

In the boiler, between the flow and return

pipes,an automatic bypass device is fitted

(a differential valve with a flow rate of

about 150 l/h) which guarantees always

minimum flow rate through the heat

exchanger, also in the case, for instance,

that all the thermostatic valves fitted on the

radiators, are closed.

Off, that there are no gas leaks.

During the 2nd quarter of a hour from the

beginning of the test no pressure reduction

is to be detected on the gas pressure

gauge. If gas leaks have to be found, use

only water soap solution or any other

specific gas leak detector which can be

available on the market. Never look for gas

leaks using a nacked flame.

Loading...

Loading...