9

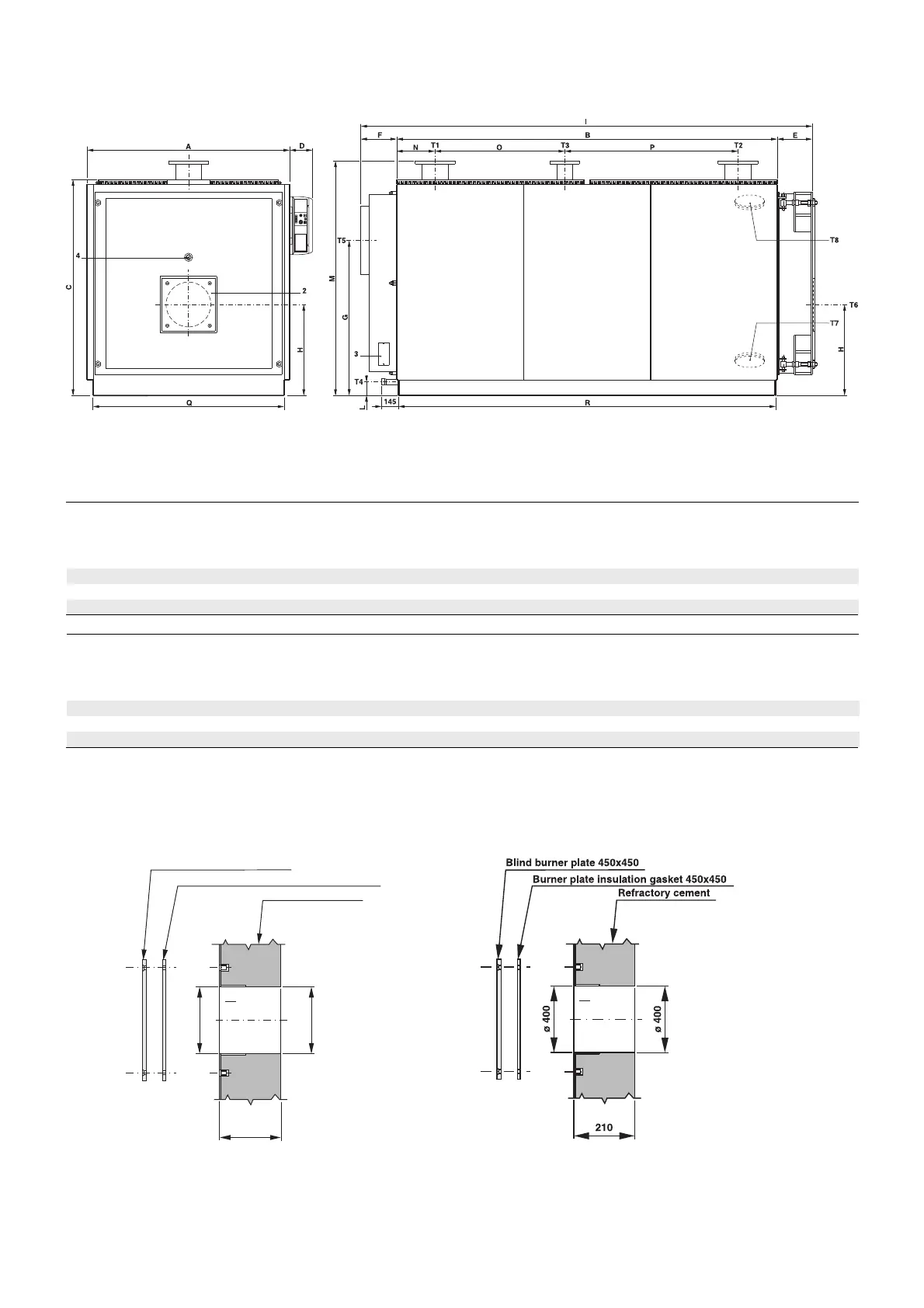

Refractory cement

Blind burner plate 450x450

Burner plate insulation gasket 450x450

ø 380

ø 380

210

I

mm

T4

ISO 7/1

T1 C.H. flow

T2 C.H. return

T3 Expansion vessel connection

T4 Boiler drain

T5 Flue socket

T6 Max. burner blast tube dia.

T7 Sludge drain

T8 Inspection door

(*) Minimum dimensions for boiler room access requirements.

(**) Hydraulic resistance for delta T 15K.

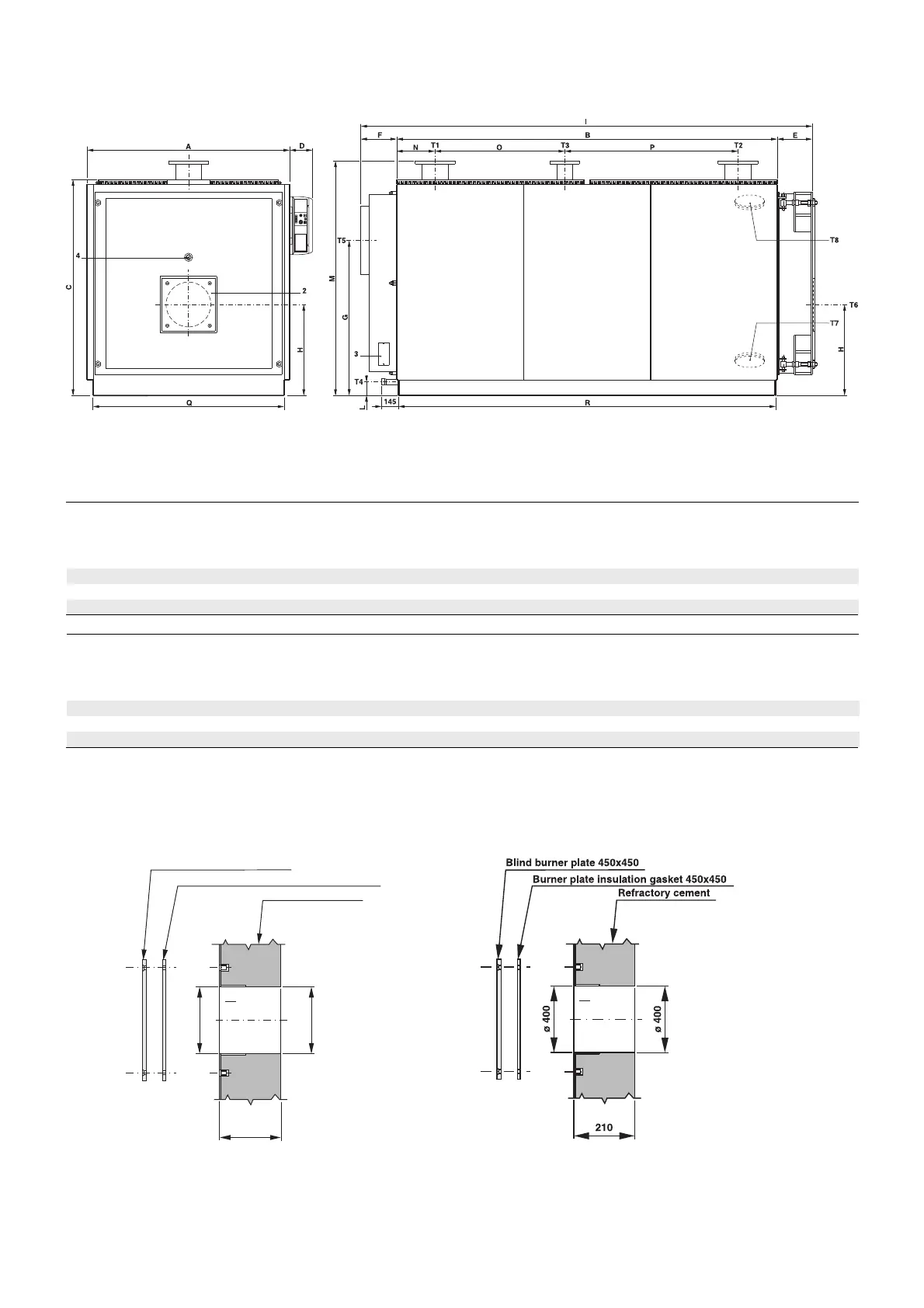

DIMENSIONS AND HYDRAULIC CONNECTIONS FOR ELLPREX 3000÷4000

ELL 3000

ELL 3500

ELL 4000

ELLPREX

Model

ELLPREX

Model

ELL 3000

ELL 3500

ELL 4000

A

mm

1720

1970

1970

B

mm

3230

3194

3594

1830

2090

2090

C

mm

190

190

190

D

mm

295

325

325

E

mm

F

mm

340

390

360

G

mm

1315

1535

1535

H

mm

772

915

915

3835

3879

4279

L

mm

115

144

144

1990

2271

2271

M*

mm

325

377

777

N

mm

1100

1060

1060

O

mm

1330

1280

1420

P

mm

1620

1870

1870

Q*

mm

3200

3164

3564

R*

mm

Nominal

Output

kW

2300÷3000

2700÷3500

3040÷4000

Nominal

Input

kW

2492÷3280

2930÷3825

3297÷4371

Water

content

l

2667

4142

4455

Water side

pressure

loss(**)

m w.c.

0,36÷0,62

0,54÷0,84

0,54÷0,85

1 Panel board

2 Burner fixing plate

3 Smoke chamber cleaning door

4 Sight glass

Smoke side

pressure

loss

mm w.c.

35÷60

47÷78

60÷80

Maximum

working

pressure

bar

6

6

6

Weight

kg

5110

6700

7500

T1

T2

UNI 2278 PN16

T3

UNI 2278 PN16

DN 125

DN 125

DN 125

DN 200

DN 200

DN 250

Rp 1½

Rp 1½

Rp 1½

T5

Øi

mm

570

620

620

T6

Ø

mm

380

400

400

DETAIL FOR DOOR DRILLING

ELL 3000

CONNECTIONS

DIMENSIONS

fig. 11

fig. 12

DETAIL FOR DOOR DRILLING

ELL 3500÷4000

fig. 13

Loading...

Loading...