Why is there excessive spatter when using my Unimig Welding System?

- JJason ThomasJul 29, 2025

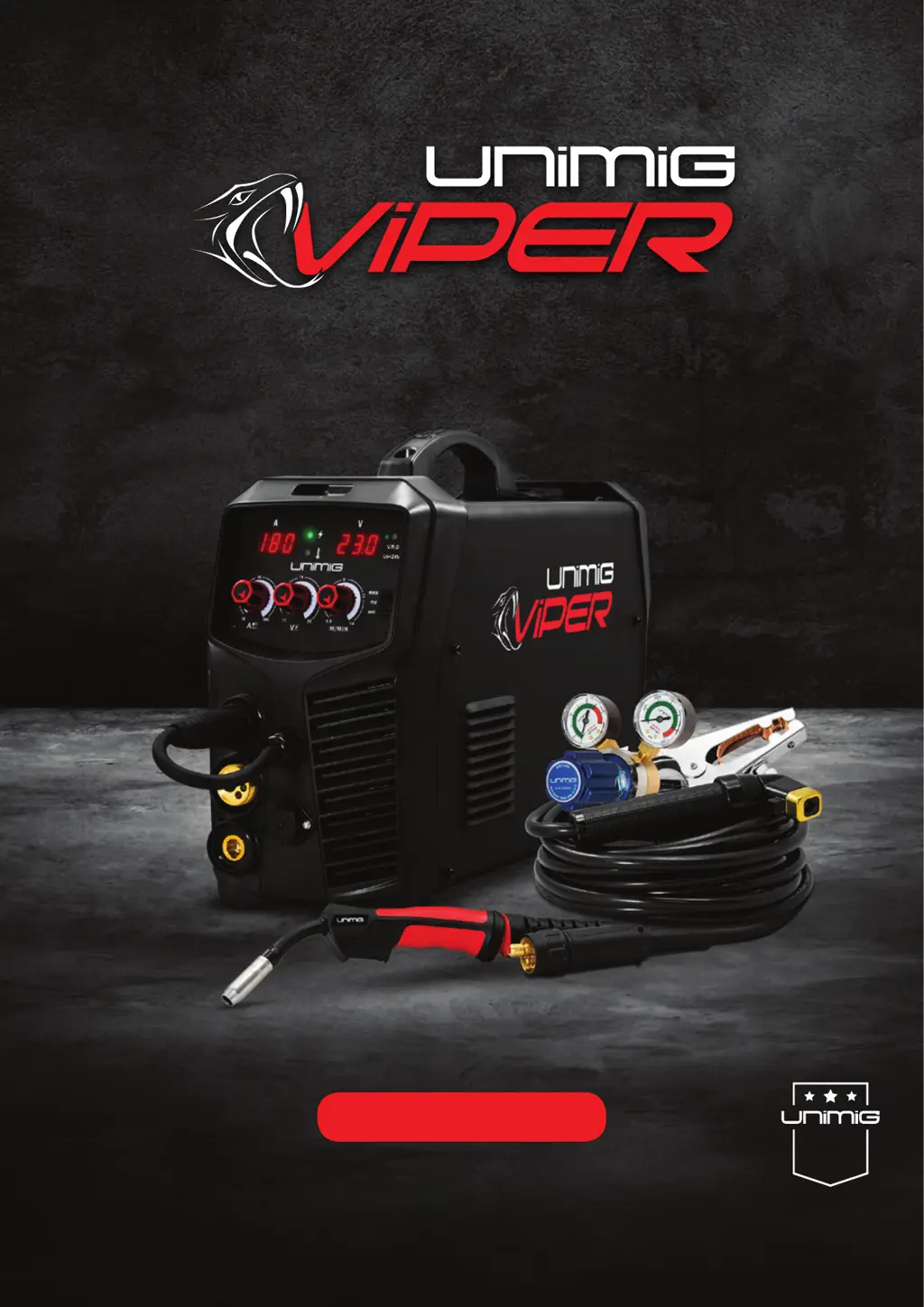

Excessive spatter when using a Unimig Welding System can occur if the wire feed speed or voltage is too high; lower these settings. The polarity could be incorrect, so ensure it matches the wire type as per the setup guide. If the torch is too far from the workpiece, move it closer. Also, remove any contaminants like paint, grease, oil, dirt, or mill scale from the base metal, and use clean, dry, rust-free wire, avoiding lubrication. Finally, ensure proper gas flow (6-12 l/min), checking for restrictions or leaks in hoses and fittings, and protect the welding area from wind.