Do you have a question about the UnionSpecial 39500 MC and is the answer not in the manual?

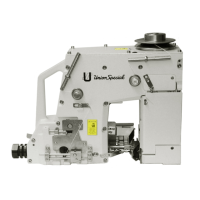

Details the features of the Hi-Styled High Speed Overseaming Machine.

Guidance on oil capacity, type, and checking oil levels for the machine.

Details Union Special needles, types, sizes, and the procedure for changing them.

Explains the initial path of threads from cones to tension guides.

Step-by-step instructions for threading the lower looper.

Detailed steps for threading the upper looper specifically for the 505 stitch.

Step-by-step instructions for threading the needle.

Guidance on regulating thread tension using tension nuts for proper stitch formation.

Guidance on maintaining adequate presser foot pressure for uniform fabric feeding.

Explains how feed eccentrics determine stitch length and differential feed.

Instructions for aligning the needle in the needle slot and setting its height.

Setting rear and front needle guards to prevent interference during operation.

Adjusting lower looper, upper looper, and spreader positions for correct stitch formation.

Adjusting feed dogs and the lower knife for proper fabric feeding and trimming.

Checking and adjusting the upper looper or spreader for adequate clearance.

Setting the upper knife to achieve the desired trim width.

How stitch length is determined by the combination of feed eccentrics.

Aligning the presser foot with the throat plate for correct fabric feeding.

Guidance on the initial steps to start operating the machine after setup.

Adjusting needle and looper threads for proper stitch formation and edge finish.

Balancing thread tensions and troubleshooting skipping stitch problems.

Instructions for assembling and adjusting the hemming guide support bracket.

Final adjustments to the edge and overhanging guides for precise hemming.

Detailed list of parts specific to Style 39500 MC with reference numbers.

Lists parts for throat plates, needle guards, lower knife, and hemming guide assemblies.

| Class | 39500 |

|---|---|

| Model | 39500 MC |

| Thread Tension | Adjustable |

| Differential Feed | Yes |

| Type | Overlock |

| Stitch Type | Overlock |

| Speed | 6, 000 SPM |

| Machine Weight | 32 kg |