At high speeds the fuel flows from the fuel chamber through the main jet and into the main discharge jet

where it is mixed with air admitted by the well vent, and the air-fuel mixture is then discharged into the air

stream of the carburetor.

CHOKE SYSTEM

The choke, consists of a valve mounted on a shaft located in the air entrance and operated externally by a

lever mounted on the shaft. The choke valve is used to restrict the air entering the carburetor. This increases

the suction on the jets when starting the engine. The choke valve is of a "semi-automatic" type, having a

poppet valve incorporated in its design, which is controlled by a spring.

The poppet valve opens automatically when the engine starts and admits air to avoid over-choking or

flooding of the engine. The mixture required for starting is considerably richer than that needed to develop

power at normal temperatures. As the engine fires and speed and suction are increased, the mixture ratio

must be rapidly reduced. This change is accomplished through adjustment of the choke valve and the

automatic opening of the poppet valve to admit more air when the engine fires.

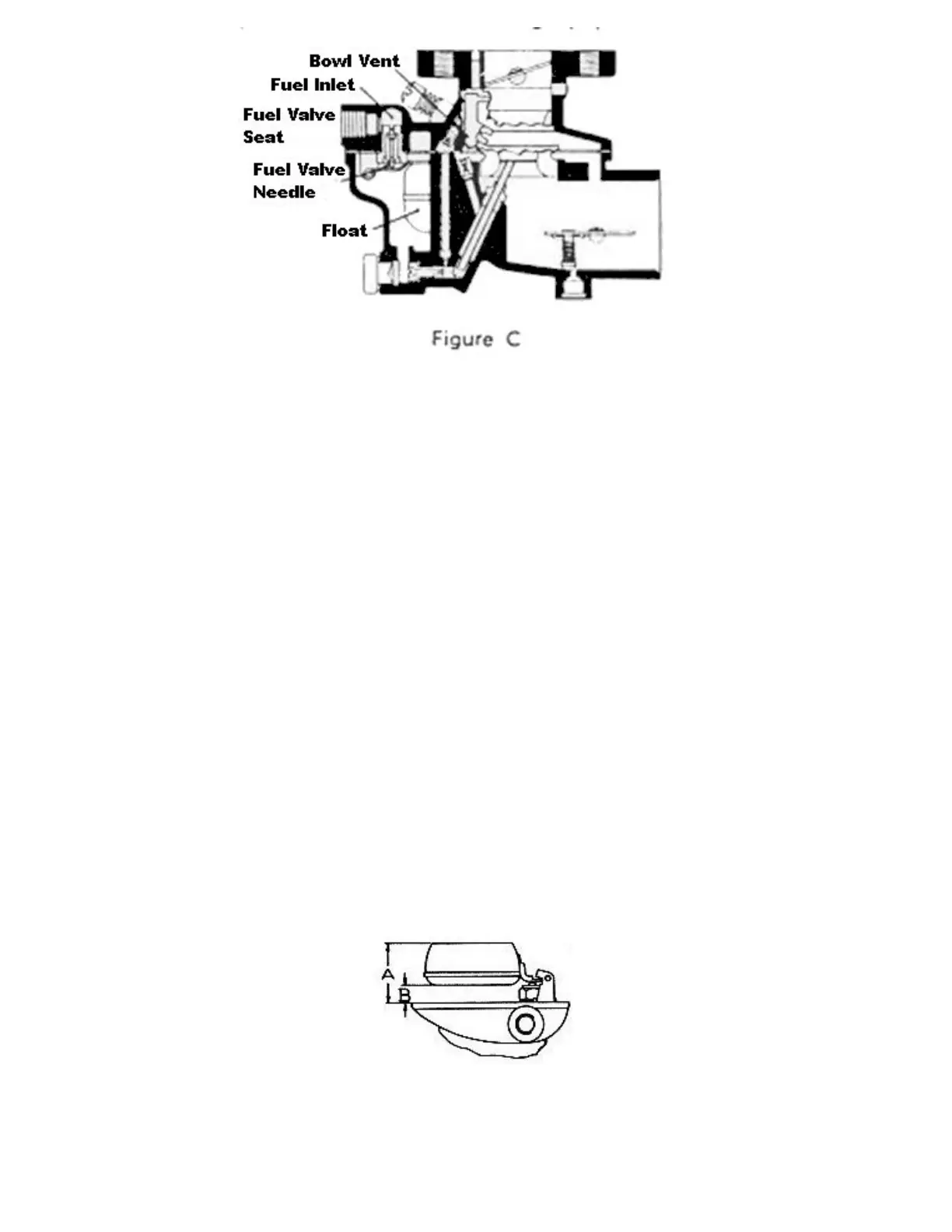

FLOAT SYSTEM

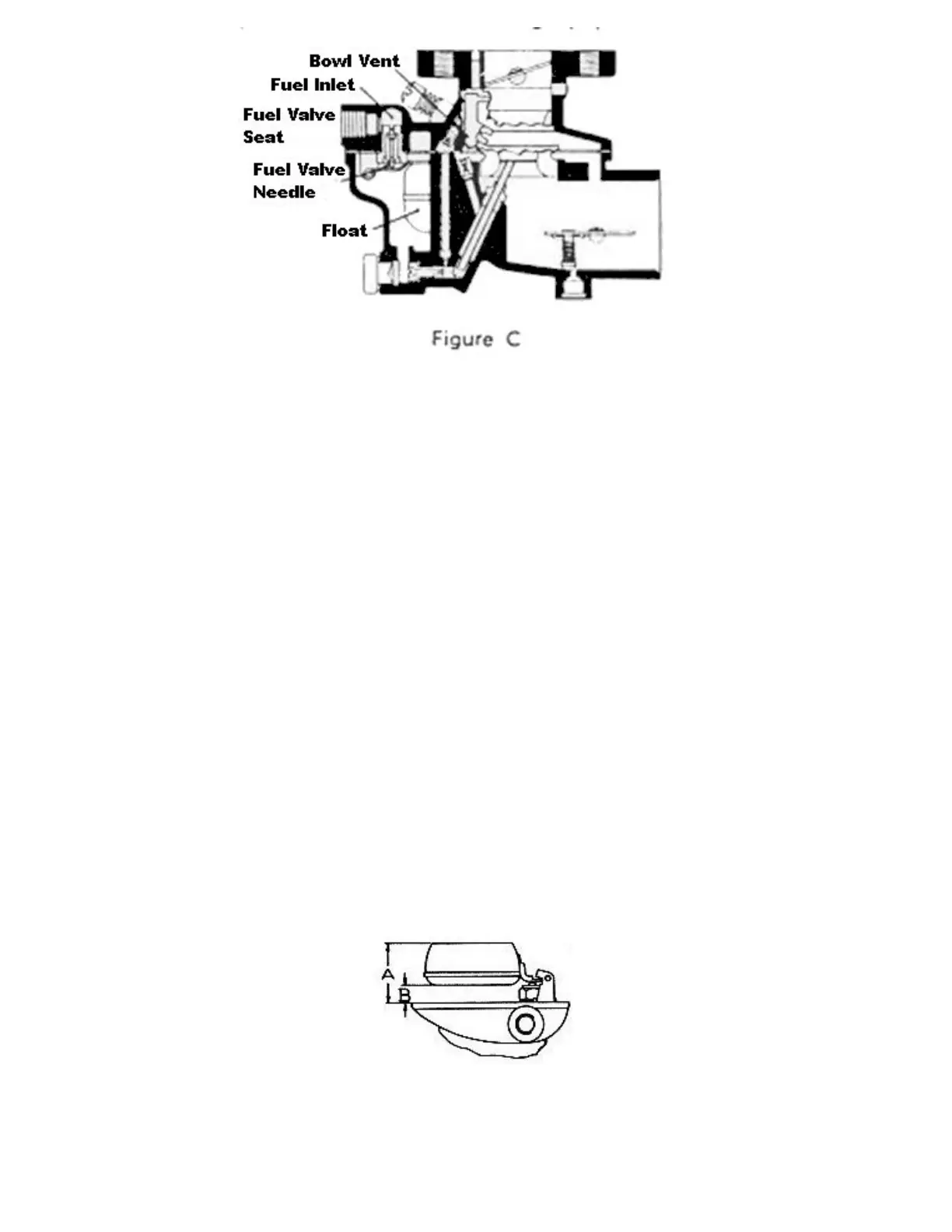

The "A" dimension should be 1-5/32" plus or minus 3/64".

Float Level. Check position or float assembly for correct measurement to obtain proper float level using

Loading...

Loading...