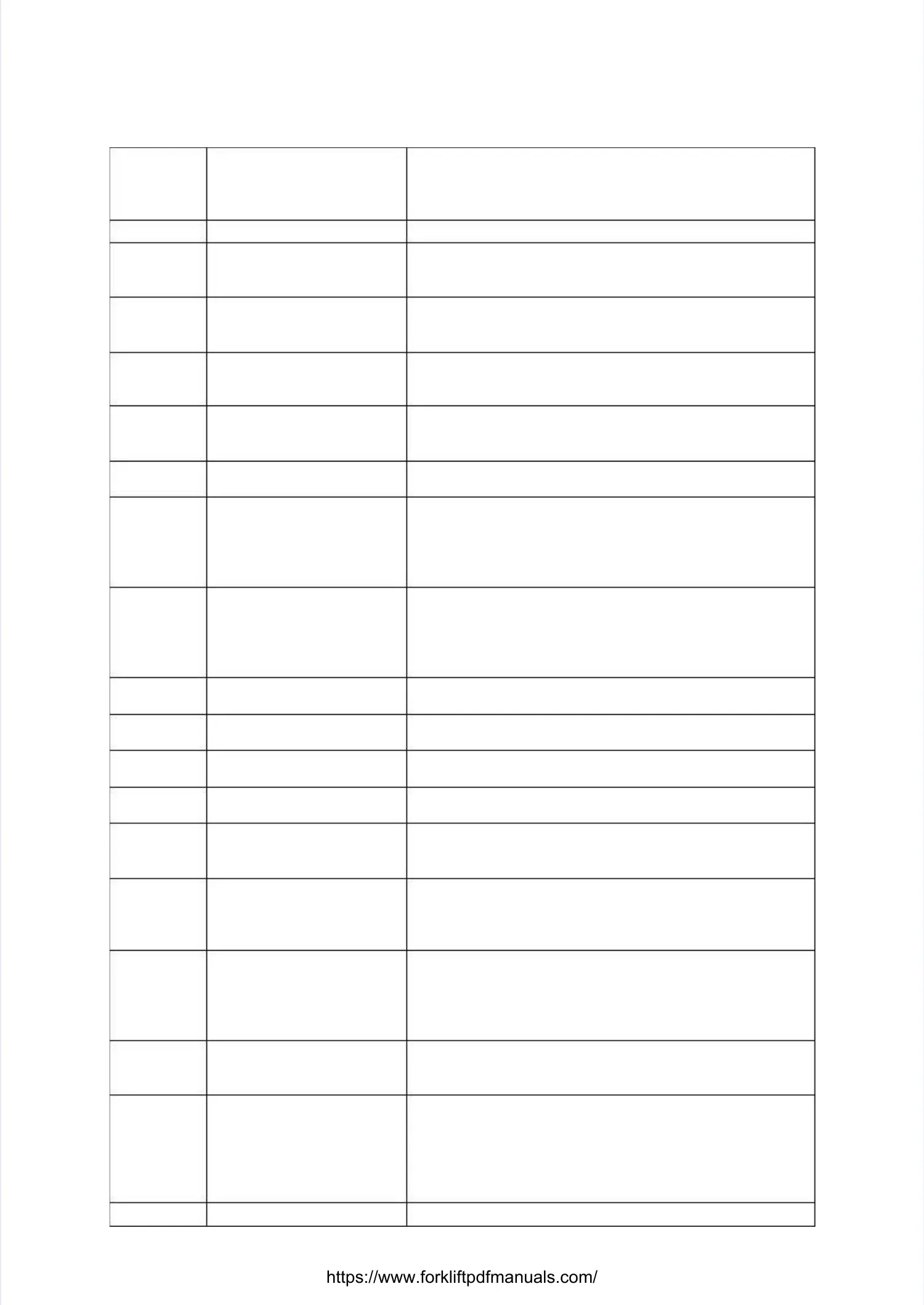

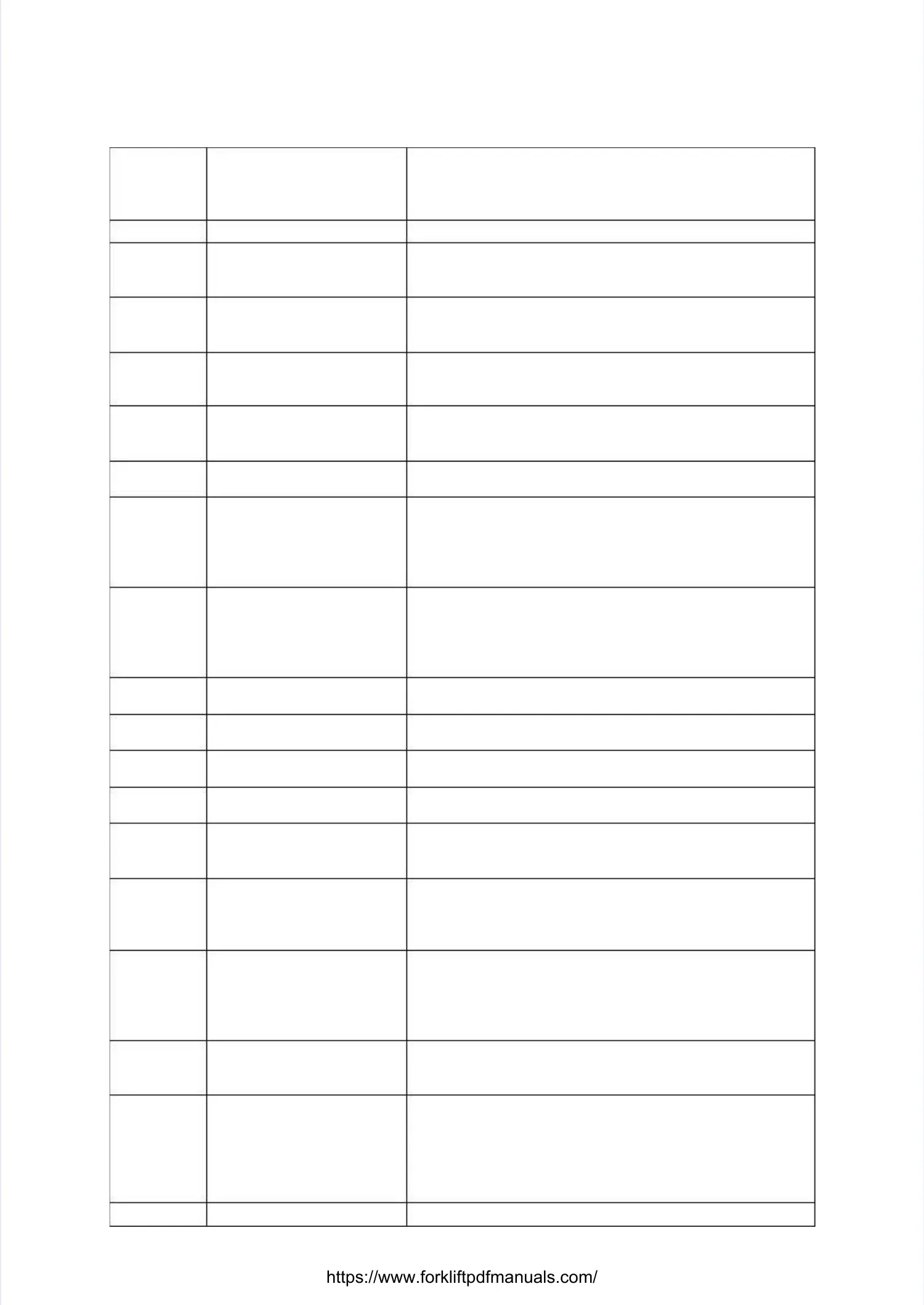

2121

InstrumentInstrument

displaydisplay

DisplayDisplay

codecode

Handheld display faultHandheld display fault

codecode

Possible causePossible cause

3. Bad crimps or faulty wiring.3. Bad crimps or faulty wiring.

3 3 , , 3 3 Coil3 Coil3 Driver Driver Open/ShortOpen/Short

1. Open or short on driver load.1. Open or short on driver load.

2. Dirty connector pins.2. Dirty connector pins.

3. Bad crimps or faulty wiring3. Bad crimps or faulty wiring

3 3 , , 4 4 Coil4 Coil4 Driver Driver Open/ShortOpen/Short

1. Open or short on driver load.1. Open or short on driver load.

2. Dirty connector pins.2. Dirty connector pins.

3. Bad crimps or faulty wiring3. Bad crimps or faulty wiring

3 3 , , 5 5 PD PD Open/ShortOpen/Short

1. Open or short on driver load.1. Open or short on driver load.

2. Dirty connector pins.2. Dirty connector pins.

3. Bad crimps or faulty wiring3. Bad crimps or faulty wiring

3 3 , , 6 6 Encoder Encoder FaultFault

1. Motor encoder failure.1. Motor encoder failure.

2. Bad crimps or faulty wiring.2. Bad crimps or faulty wiring.

3. See 1311 menu Monitor » Motor: Motor 3. See 1311 menu Monitor » Motor: Motor RPMRPM

3 3 , , 7 7 Motor Motor OpenOpen

1. Motor U, V, W line is open.1. Motor U, V, W line is open.

2. Bad crimps or faulty wiring.2. Bad crimps or faulty wiring.

3 3 , , 8 8 Main Main Contactor Contactor WeldedWelded

1. Main contactor tips are welded closed.1. Main contactor tips are welded closed.

2. Motor phase U is disconnected or open.2. Motor phase U is disconnected or open.

3. An alternate voltage path (such as an external3. An alternate voltage path (such as an external

precharge resistor) is providing a current to the capacitorprecharge resistor) is providing a current to the capacitor

bank (B+ terminal).bank (B+ terminal).

3 , 93 , 9

Main Contactor Did NotMain Contactor Did Not

CloseClose

1. Main contactor did not close.1. Main contactor did not close.

2. Main contactor tips are oxidized.2. Main contactor tips are oxidized.

3. External load on capacitor bank (B+ terminal) that3. External load on capacitor bank (B+ terminal) that

prevents capacitor bank from charging.prevents capacitor bank from charging.

4. Blown B+ fuse.4. Blown B+ fuse.

4 4 , , 1 1 Throttle Throttle Wiper Wiper HighHigh

1. Throttle pot wiper voltage too high.1. Throttle pot wiper voltage too high.

2. See 1311 menu Monitor » Inputs: Throttle Pot2. See 1311 menu Monitor » Inputs: Throttle Pot

4 4 , , 2 2 Throttle Throttle Wiper Wiper LowLow

1. Throttle pot wiper voltage too low.1. Throttle pot wiper voltage too low.

2. See 1311 menu Monitor » Inputs: Throttle Pot2. See 1311 menu Monitor » Inputs: Throttle Pot

4 4 , , 3 3 Brake Brake Wiper Wiper HighHigh

1. Brake pot wiper voltage too high.1. Brake pot wiper voltage too high.

2. See 1311 menu Monitor » Inputs: Brake Pot2. See 1311 menu Monitor » Inputs: Brake Pot

4 4 , , 4 4 Brake Brake Wiper Wiper LowLow

1. Brake pot wiper voltage t1. Brake pot wiper voltage too low.oo low.

2. See 1311 menu Monitor » Inputs: Brake Pot2. See 1311 menu Monitor » Inputs: Brake Pot

4 4 , , 5 5 Pot Pot Low Low OvercurrentOvercurrent

1. Combined pot resistance connected to Pot Low is too1. Combined pot resistance connected to Pot Low is too

low.low.

2. See 1311 menu Monitor » Outputs: Pot Low2. See 1311 menu Monitor » Outputs: Pot Low

4 4 , , 6 6 EEPROM EEPROM FailureFailure

1. Failure to write to 1. Failure to write to EEPROM memory.EEPROM memory.

This can be caused by EEPROM memory writes initiatedThis can be caused by EEPROM memory writes initiated

by VCL, by the CAN bus, by adjusting parameters withby VCL, by the CAN bus, by adjusting parameters with

the 1311, or by loading new software into the controller.the 1311, or by loading new software into the controller.

4 4 , , 7 7 HPD/Sequencing HPD/Sequencing FaultFault

1. Keyswitch, interlock, direction, and throttle inputs1. Keyswitch, interlock, direction, and throttle inputs

applied in incorrect sequence.applied in incorrect sequence.

2 Faulty wiring, crimps or transfer switches at keyswitch,2 Faulty wiring, crimps or transfer switches at keyswitch,

interlock, direction or throttle inputs.interlock, direction or throttle inputs.

3. See 1311 menu Monitor » Inputs.3. See 1311 menu Monitor » Inputs.

4 4 , , 7 7 Emer Emer Rev Rev HPDHPD

1. Emergency Reverse operation has concluded, but the1. Emergency Reverse operation has concluded, but the

throttle, forward and reverse inputs, and interlock havethrottle, forward and reverse inputs, and interlock have

not been returned to neutral.not been returned to neutral.

4 4 , , 9 9 Parameter Parameter Change Change FaultFault

1. This is a safety fault caused by a change in certain1. This is a safety fault caused by a change in certain

1311 parameter settings so that the vehicle will not1311 parameter settings so that the vehicle will not

operate until keyswitch input is cycled.operate until keyswitch input is cycled.

For example, if a user changes the Throttle Type thisFor example, if a user changes the Throttle Type this

fault will appear and require cycling the keyswitch inputfault will appear and require cycling the keyswitch input

before the vehicle can operate.before the vehicle can operate.

6 6 , , 8 8 VCL VCL Runtime Runtime Error Error 1. 1. VCL VCL code code encountered encountered a a runtime runtime error.error.

Loading...

Loading...