Installation Instructions, Viper 2000 Control System

PRD0167E01en UWE Verken AB 2(6)

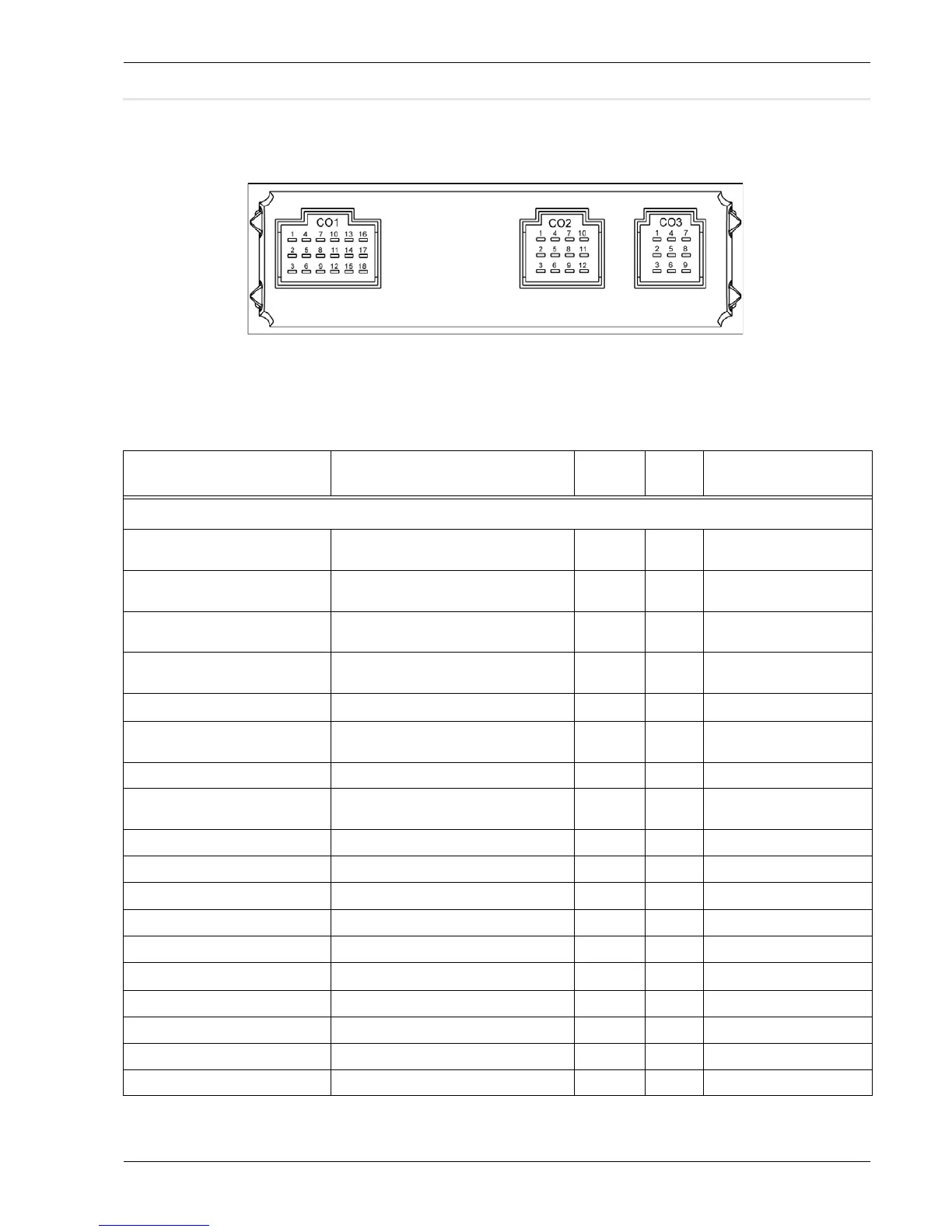

Connection of display unit (syst 1)

Connections to components should be performed according to

the table below::

Table 1: Display unit

Description Comment

See

footnote

Pin Type

Defroster: CO1 18 pole

Valve, Defroster circuit Open = 0V. Direct Drive / Motor valve driver.

Inverted.

2) CO1:1 Solid state outp. 1.9A

Valve, Driver’s convector circuit Open = 24V. Direct Drive / Motor valve

driver. Non-inverted

2) CO1:2 Solid state outp. 1.9A

Valve, Defroster circuit Open = 24V. Direct Drive / Motor valve

driver. Non-inverted

2) CO1:3 Solid state outp. 1.9A

Valve, Driver’s convector circuit Open = 0V. Direct Drive / Motor valve driver.

Inverted

2) CO1:4 Solid state outp. 1.9A

Temp sensor, Defroster air CO1:5

Analog NTC 4,7k

Ω

Valve, Defroster circuit position feed-

back

Open = High Voltage 2) ,4) CO1:6 Analog 0 - 33V

Flap Fresh/Recirc, defroster air Rec = +24V. Source / sink CO1:7 Solid state outp. 1.9A

Valve, Driver’s Convector circuit pos

feedback

Open = High Voltage 2) ,4) CO1:8 Analog 0 - 33V

Temp sensor GND, defroster air CO1:9 Sensor ground

Flap Fresh/Recirc defroster air Rec = 0V. Source / sink CO1:10 Solid state outp. 1.9A

Temp sensor, Outside air CO1:11

Analog NTC 4,7k

Ω

Temp sensor GND, Outside air CO1:12 Sensor ground

Flap Floor/Screen Scr = +24V. Source / sink CO1:13 Solid state outp. 1.9A

Temp sensor, Driver’s place CO1:14

Analog NTC 4,7k

Ω

Temp sensor GND, Driver’s place CO1:15 Sensor ground

Flap Floor/Screen Scr = 0V. Source / sink CO1:16 Solid state outp. 1.9A

Flap Floor/Screen, position feedb. Floor = High voltage Scr = 0V 1) ,4) CO1:17 Analog 0 - 33V

Flap Fresh/Recirc, position feedb. Recirc= High voltage Fre = 0V 1) ,4) CO1:18 Analog 0 - 33V

Loading...

Loading...