10

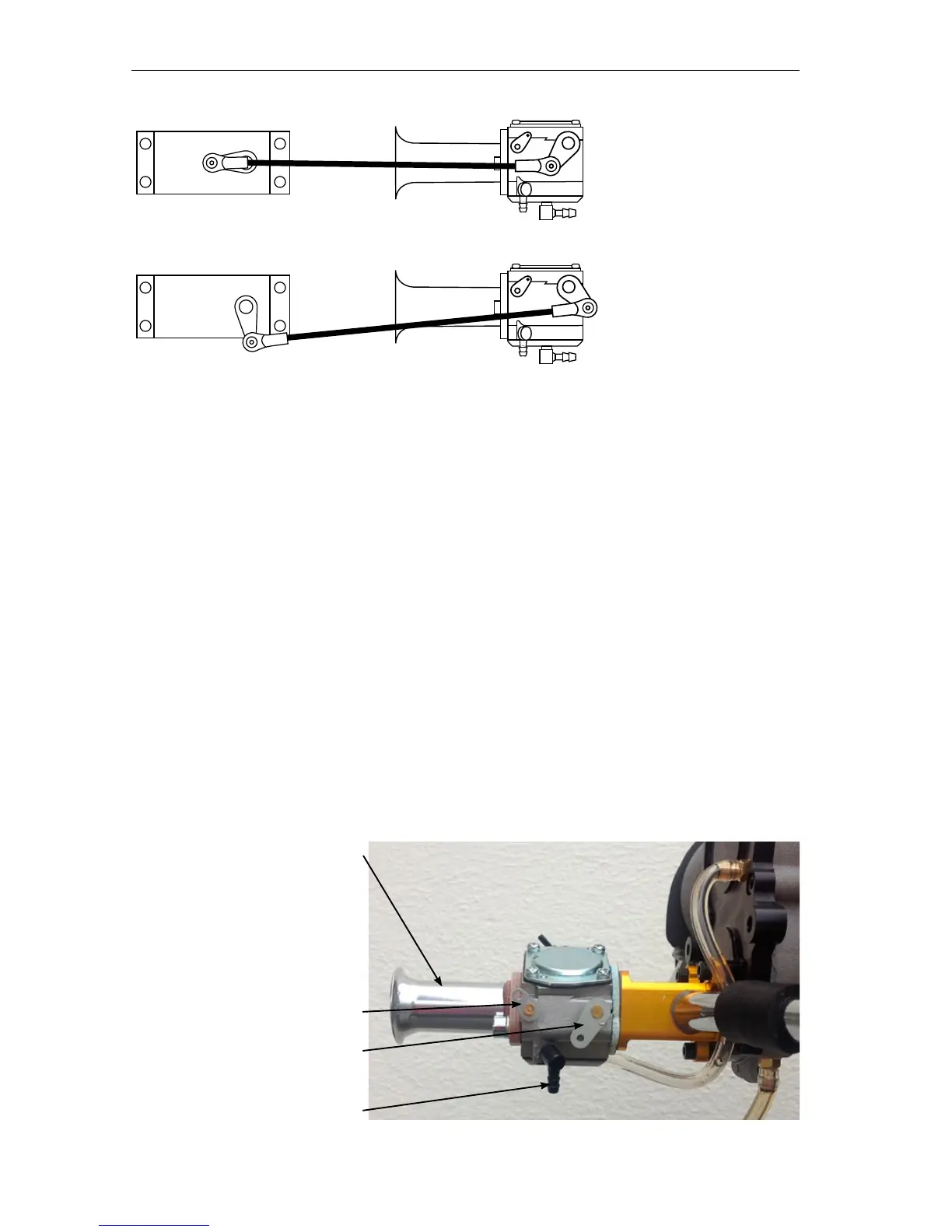

It is a good idea to make a throttle linkage like the one showed above. The throttle

valve will move slower on idle than on full throttle. As a result the engine will accelerate

faster and more reliable from low idle. The use of a throttle curve in your transmitter

will NOT have the same eect, because it has no inuence on the servo speed. For

example, if you move the throttle stick fast from idle to full throttle, the transmiter

will not follow the trottle curve, it will only transmit the command „full throttle“. The

throttle valve will open on the full servospeed. The servoarm should have a lenght of

about 14 mm to maintain the full servotrack.

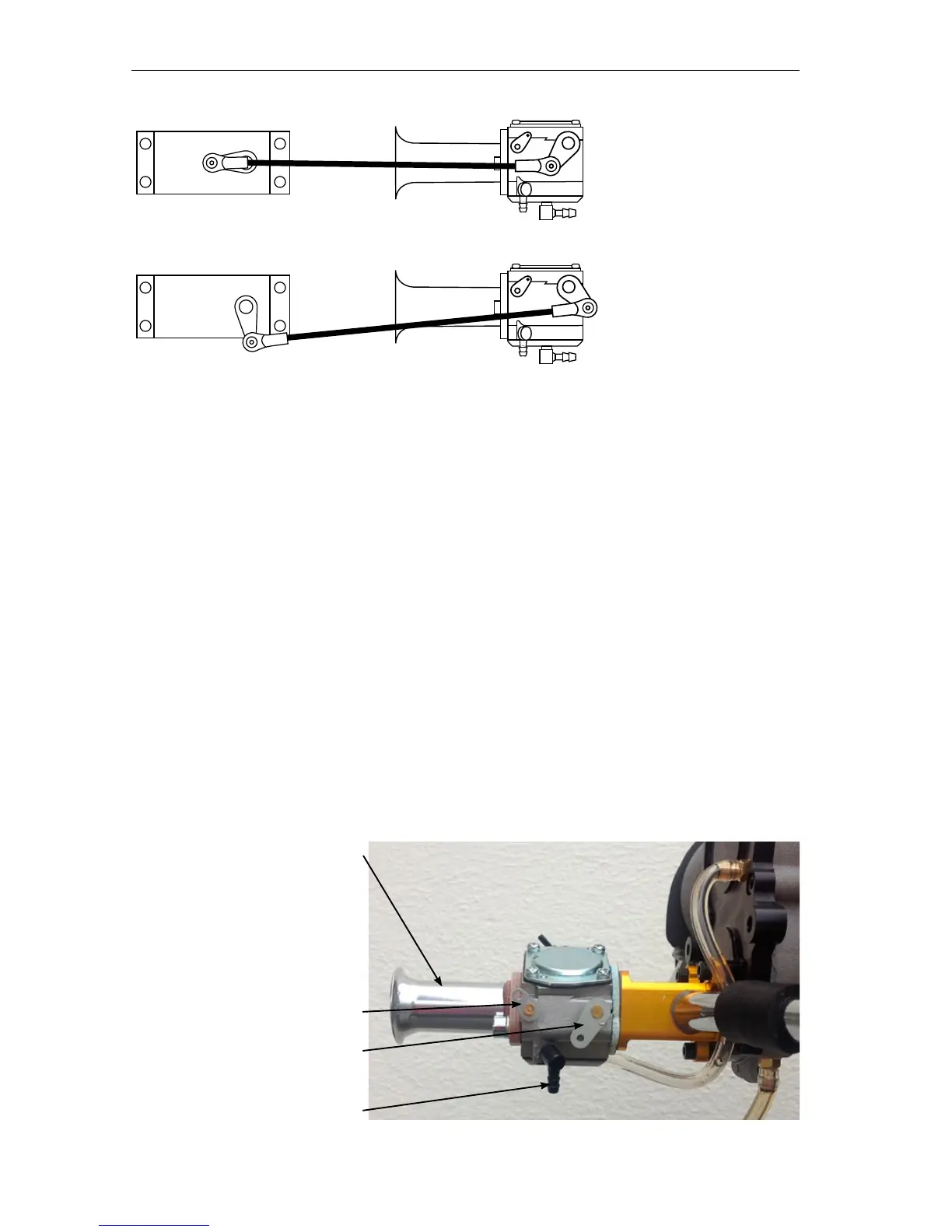

To link the throttle valve drill a 2 mm hole into the existing arm and attach a ball joint.

Keep the throttle linkage as light as possible, a carbon rod is the best choice. By no

means remove the spring. The life-time of the throttle valve bearing of the carburet-

tor depends on this spring and a light linkage. In the appendix you can see several

pictures of my installation of the engine in my 3 meter EMW Pitts.

I actuate the choke with a servo too. This gives me the opportunity to shut o the

engine, without using an electronic switch.

Choke arm

Throttle arm

Fuel nipple

The intake RAM tube is

absolutely neccesary!

Without it, the engine will

run too lean.

Throttle valve completly closed

Full throttle

Loading...

Loading...