113

Model Code Page

22. Fuel system

1. 9. 1992

6000--8750 223 5

G. Removing injec tors

1. Clean the injectors and the area around them. Disconnect

the delivery pipes and the leak---off pipes.

9051 71300

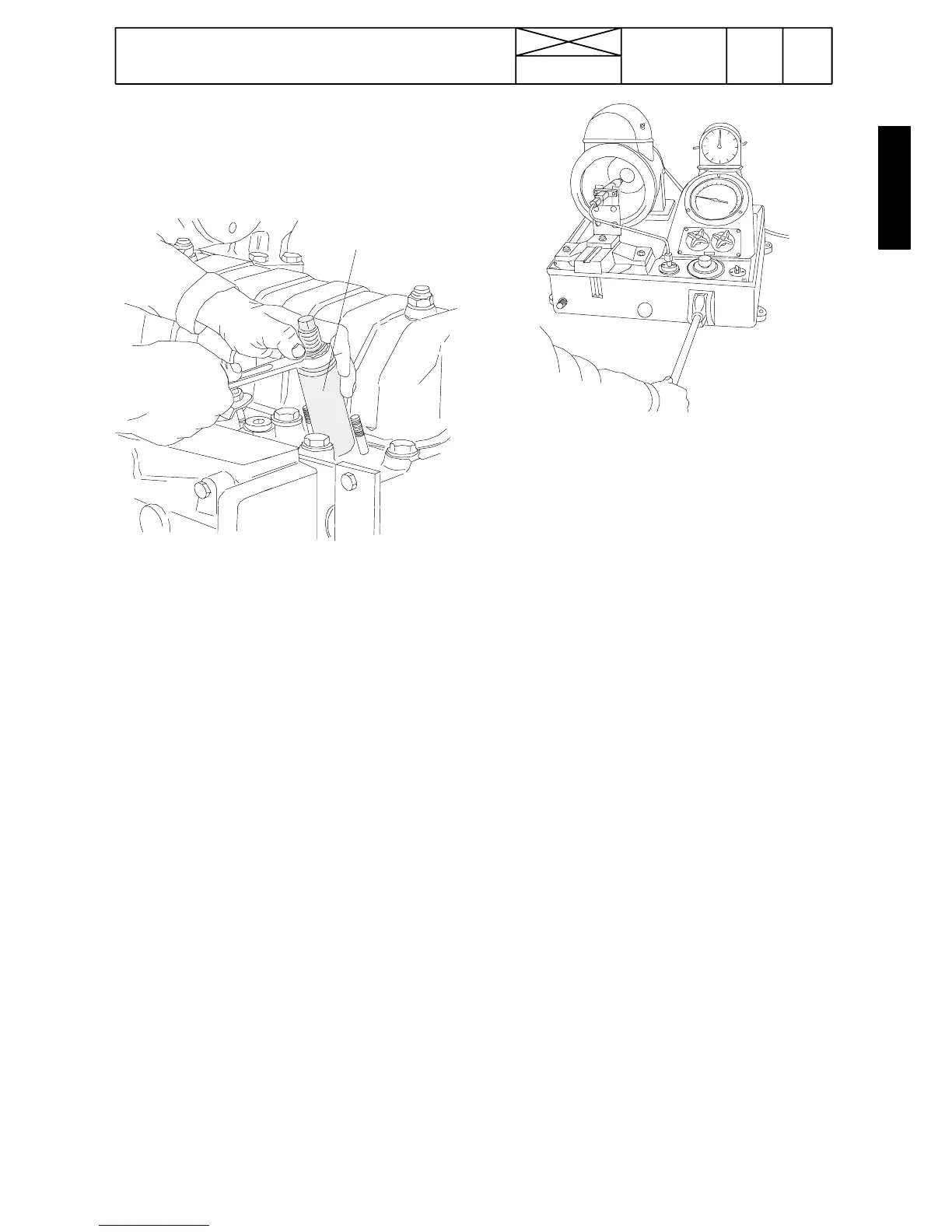

3. Remove the injector attaching nuts (13 mm) and remove

the injecto r from the cylinder head. Fit protecti ve plugs to all

connections. If the injector does not rise by hand, use puller

9051 71300.

4. Remove the sealing washers from the bottom of the injector

location in the cylinder head if they do no come out with the

injector

H. Inspecting injectors

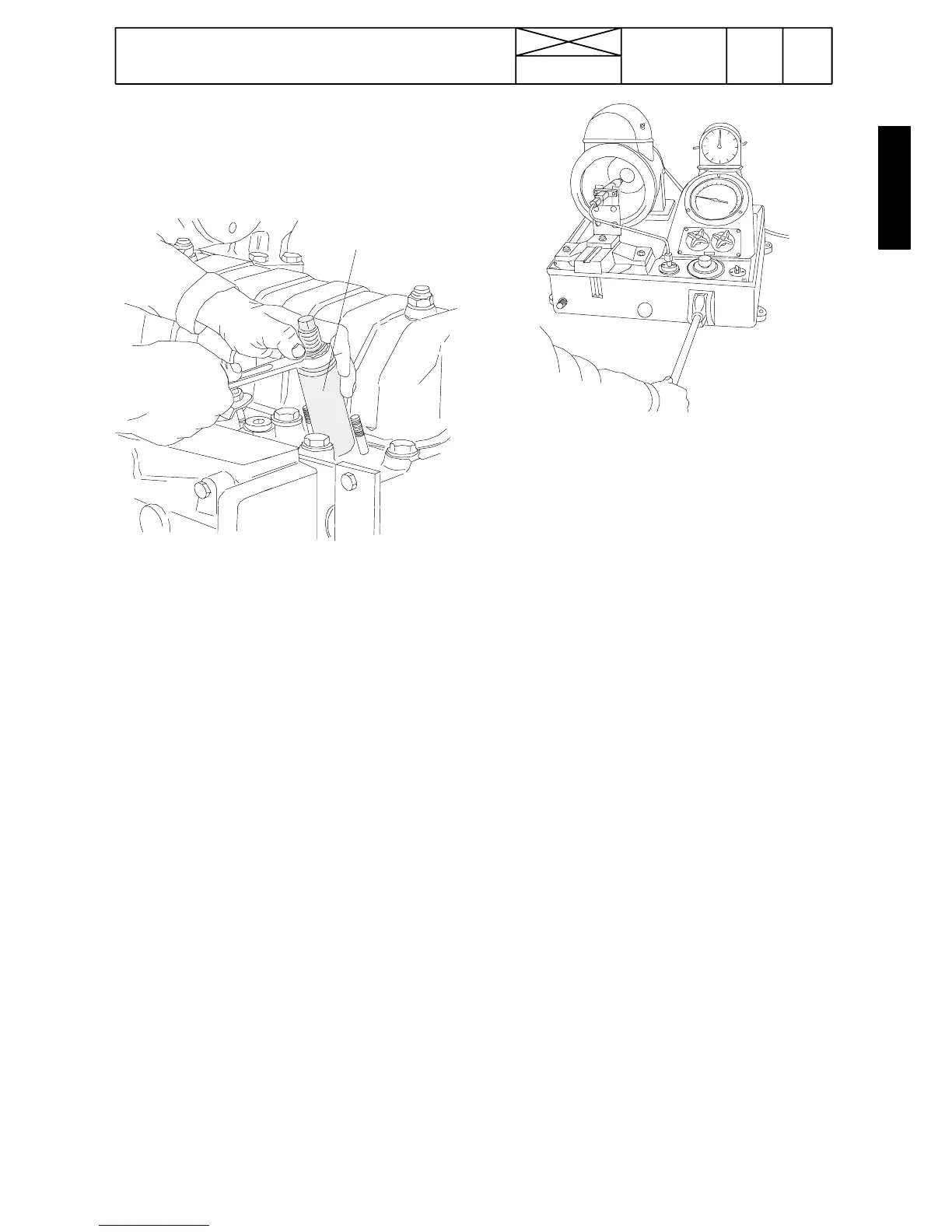

N.B. When pressure testing the injectors, it is important to

avoid the nozzle end as the fuel jetting out easily penetrates

the skin. Also bear in mind that the fuel ”mist” is dangerous to

inhale.

1. Clean the injector with cleaning fluid and a soft brush.

The carbon deposits must not be knocked off or removed in

anyotherwaywhichmaydamagethenozzle.

2. Secure the injector in a test bench and check the follow-

ing:

--- injector opening pressure

--- the properties of the chattering (creaking) sound and the

form of the spray pattern

--- sealing of nozzle valve against its seat

Opening pressure

Pump a few times to fill the injector. Increase the pressure in

the injector until the chatter ing (cre aking) sound becomes

audible. Read off the opening pressure of the injector. If the

opening pressure deviates from the given value (230±5 bar),

the injector shoul d be taken apart and checked.

Adjustment is achieved by changing the shims. The thickness

of the shims varies from 1.00---1,90 mm and they are available

in increments of 0,05 mm. A thicker shim will raise the opening

pressure while a thinner one lowers it. A difference in shim

thickness of 0,05 mm changes the opening pressure by ap-

prox. 5,0 bar. As the opening pressure of the injector drops

slightly after adjustment, the opening pressure should be set

toapproximately 10 bar above thevalue given in thespecifica-

tions. This value applies both to new and used injector.

Chattering sound properties

Testing with a hand powered pump does not create the same

circumst ances as when the injectoris fitted inthe engine.Only

with new nozzles are the test results reliable. With used

nozzles, there is no chattering (creaking) sound when the

tester is pumped at a certain rate. This has to do with the de-

sign of the nozzles.

However, with a rapid pumping on the tester handle, it should

be possible to hear the chattering (creaking) sound or/and

see a mist of the fuel jetting out.

Loading...

Loading...