4 / 4

3 Logging record

Protocol Serial number SN

Motor VRM2

Pump vapour TE K

Test step description OK NOK

Coupling

Pump fitted

Tightening torque

Functional / visual check

Date:________________________________

Tester:________________________________

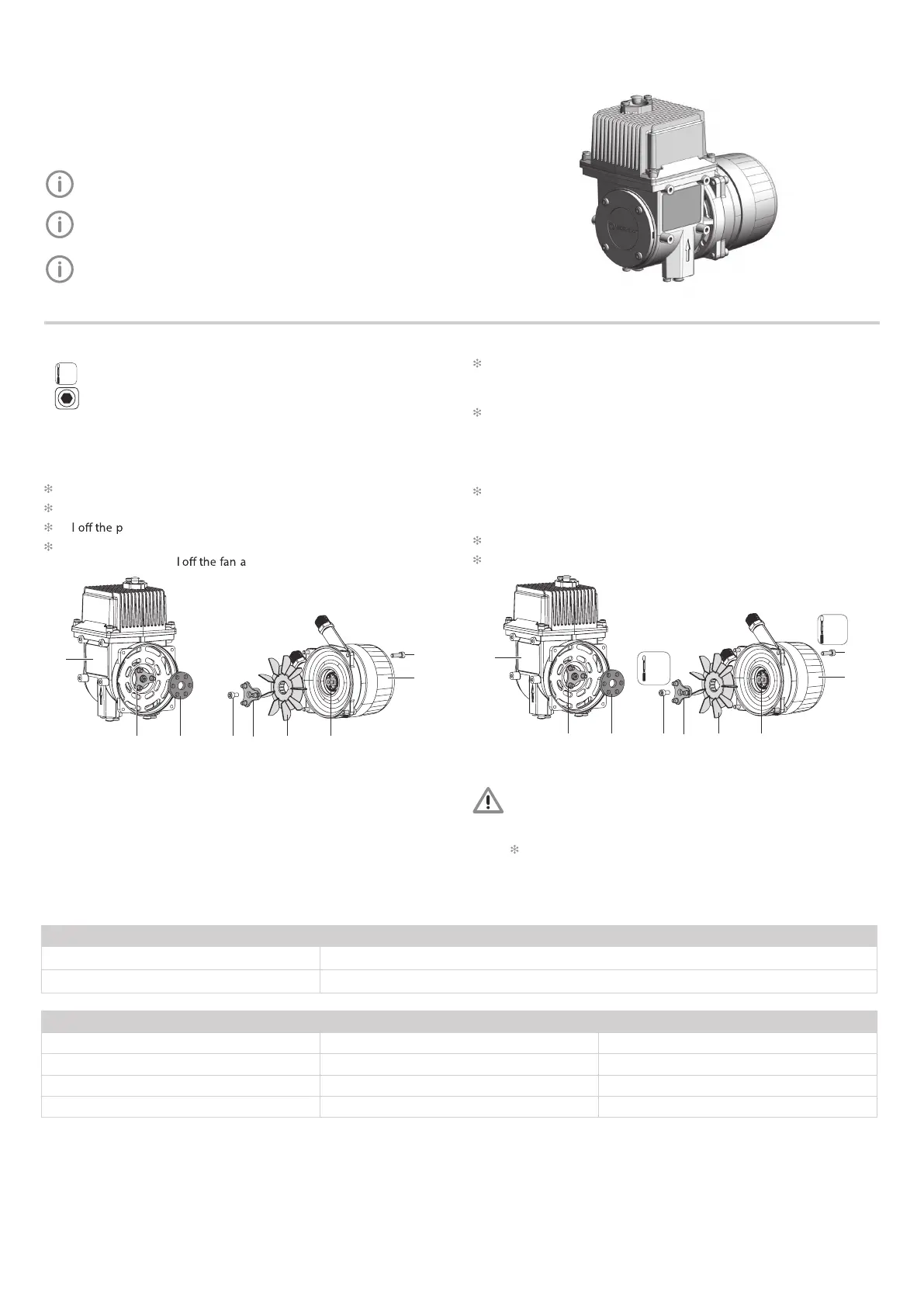

2.2 Final assembly

Slide the new fan assembly onto the motor shaft (630, 620) and tighten

the screw (60) with 12 Nm tightening torque. S ecure the thread with

anaerobic adhesive.

Place a new rubber element (600) onto the motor end of the coupling el-

ement. When doing so ensure that the 3 drive dogs of the motor end

coupling element (630) are displaced by one borehole to the 3 drive

dogs (630) of the pump end coupling element and engage the rubber el-

ement.

Slide the pump (590) onto the motor flange while taking into considera-

tion the position of the coupling element. The pump flange must lie on

the motor (650).

Tighten the fixing s crews (90) with a torque of 5 - 6 Nm.

Re-connect the lines to the pump.

630

630

620

600 60

90 (4x)

610

Nm

12

Nm

5-6

590

650

WARNING

Explosion hazard from spark formation

The pump must be operated with the rubber element

Check for correct seating of the rubber element.

1 Tools required

–

Nm

Torque wrench

–

Allen key S W 5

2 Installation

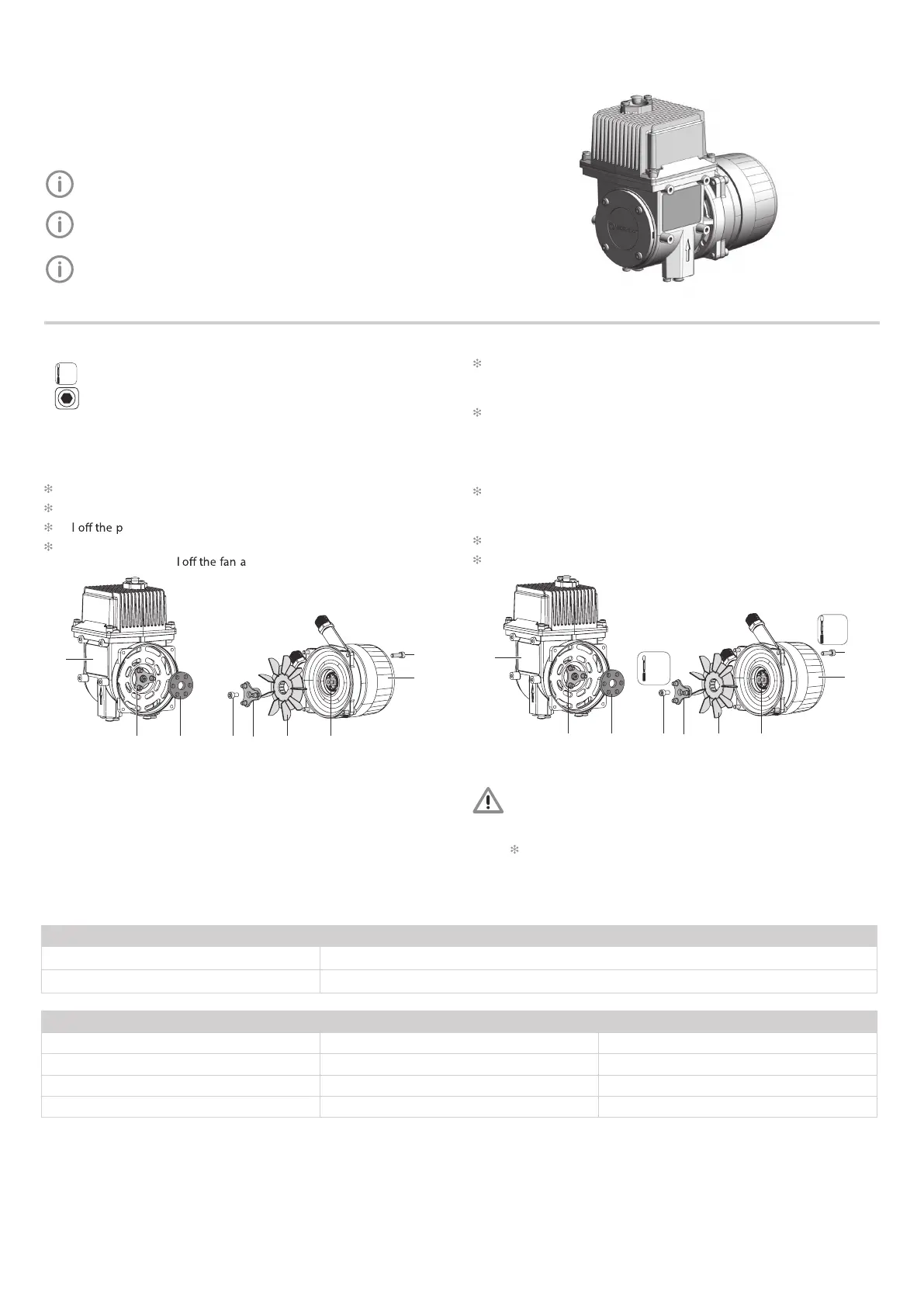

2.1 Disassembly

Remove the lines from the pump (590)

Disconnect the pump-motor s crew connections (90).

Pul ump from the motor (650).

If necessary, disassemble the fan assembly from the motor. Disconnect

the screw (60) and pul

ssembly from the motor s haft (610).

630

630

620

600 60

90 (4x)

610

650

590

60 Fan assembly screw

90 Fixing screw (motor pump flange)

590 P ump

600 R ubber element

610 Motor s haft

620 Fan wheel

630 C oupling element

650 Motor

Vapor Recovery VaporTEK Pump Field Replacement

The following information supplements the unit Assembly and Operating In-structions.

Comply with the specifications of the unit Assembly and Operating Instructions as a general

rule. These instructions include important information such as safety instructions and

information on setup, electrical connection, cleaning etc.

Refitting may only be carried out by a qualified person or one of

our service technicians.

Any repairs exceeding routine maintenance

are not permitted.

Images are shown schematically

Loading...

Loading...