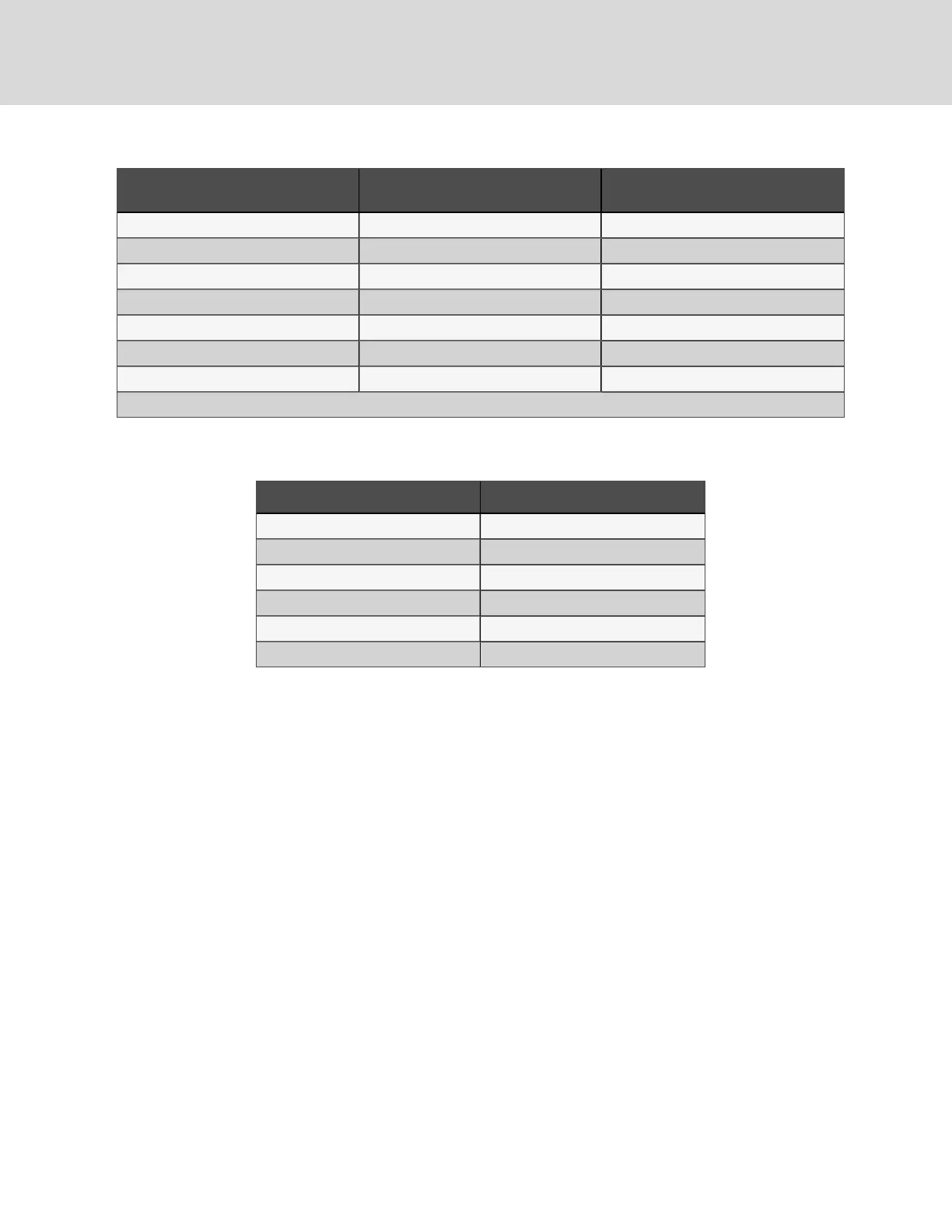

Line Size,

O.D., in.

Liquid Line, lb (kg) Suction Line, lb (kg)

3/8 3.2 (1.4) —

1/2 5.9 (2.7) 0.2 (0.1)

5/8 9.6 (4.3) 0.4 (0.2)

3/4 14.3 (6.4) 0.6 (0.3)

7/8 19.8 (8.8) 0.8 (0.4)

1-1/8 33.8 (15.1) 1.4 (0.6)

1-3/8 51.5 (23.0) 2.1 (1.0)

Source:DPN003099 Rev. 1

Table 4.5 Interconnecting piping refrigerant charge for R-410A, lbper 100ft (kgper30m)

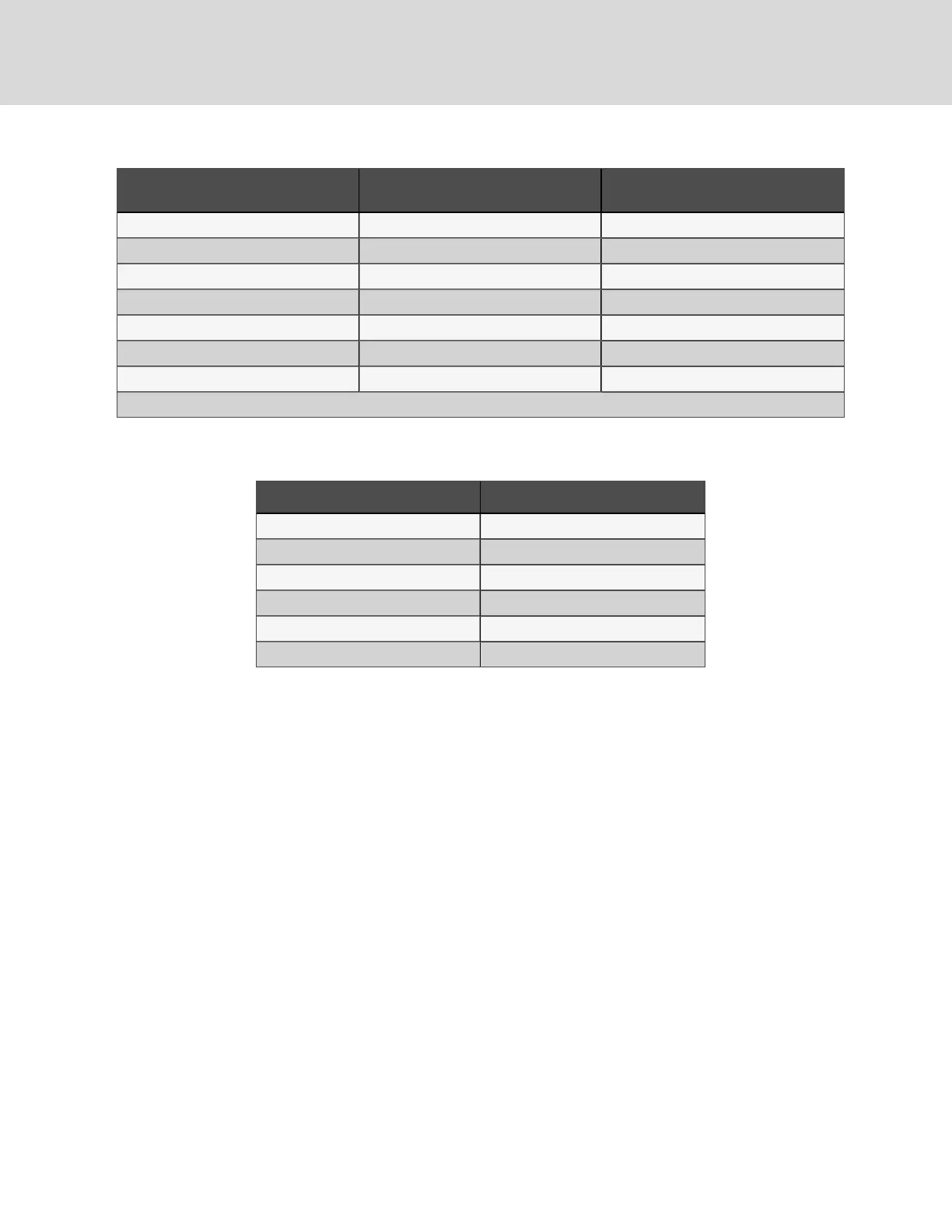

Model # Charge, lb (kg)

PFD037A-*L1 13.4 (6.1)

PFD037A-*H1 27 (12.2)

PFD054A-*L1 27 (12.2)

PFD067A-*L1 27 (12.2)

PFDZ67A-*L1 57 (25.8)

PFD067A-*H1 57 (25.8)

Table 4.6 Liebert® PFD R-410A refrigerant charge

4.2.2 Additional Oil Requirements for Digital-scroll Compressors

NOTICE

Risk of improper compressor lubrication. Can cause compressor and refrigerant system

damage.

Failure to use oil types, viscosities and quantities recommended by the compressor

manufacturer may reduce compressor life and void the compressor warranty.

• Do not mix polyolester (POE) and mineral-based oils.

• Do not mix oils of different viscosities.

• Consult your Vertiv sales representative, visit https://www.vertivco.com/en-us/support/,

or contact the compressor manufacturer if questions arise.

System charges may require additional oil charge to be added. See Table 4.7 on the facing page, for the

amount required for various system charge levels.

After the system has been fully charged with refrigerant, use a hand pump to add the additional oil at the

suction side of the system while the system is running.

On the tag marked “Oil Added Field Service Record,” attached to each compressor, record the date the oil

was added and the amount of oil added.

Vertiv | Liebert® Mini-Mate™ Installer/User Guide

18

Loading...

Loading...