9 10

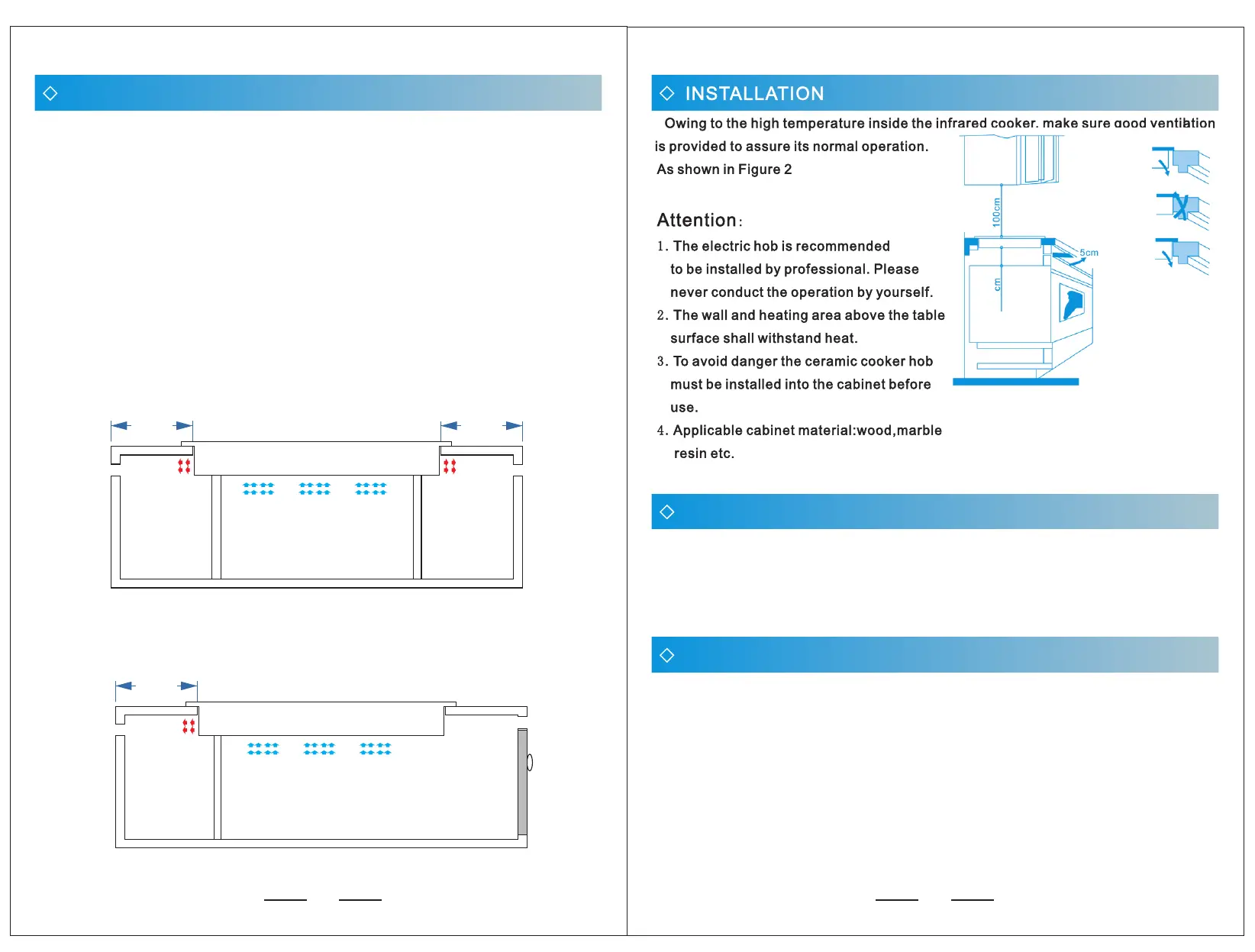

When the machine is embedded, to ensure the normal use of the machine and

better heat dissipation.

Requirements:

1. 30-50mm heat dissipation should be left on the left and right sides and behind.

2. The counter interior should be as large as possible to ensure that enough cold

air is sucked into the machine.

3. Inlet air (cold air) must be separated from outlet air (hot air) space.

4. The air inlet and outlet space of the counter leave air roar.

Positive renderings

30.00 mm

30.00 mm

left

right

Induction cooker

Counter space

Heat flow

The cold air

Exhaust roar

Heat flow

Exhaust roar

30.00 mm

after

Air inlet

Cupboard door

Induction cooker

Heat flow

Exhaust roar

The cold air

Counter space

Side view

HEAT DISSIPATION STRUCTURE INSTALLATION DRAWING

1515

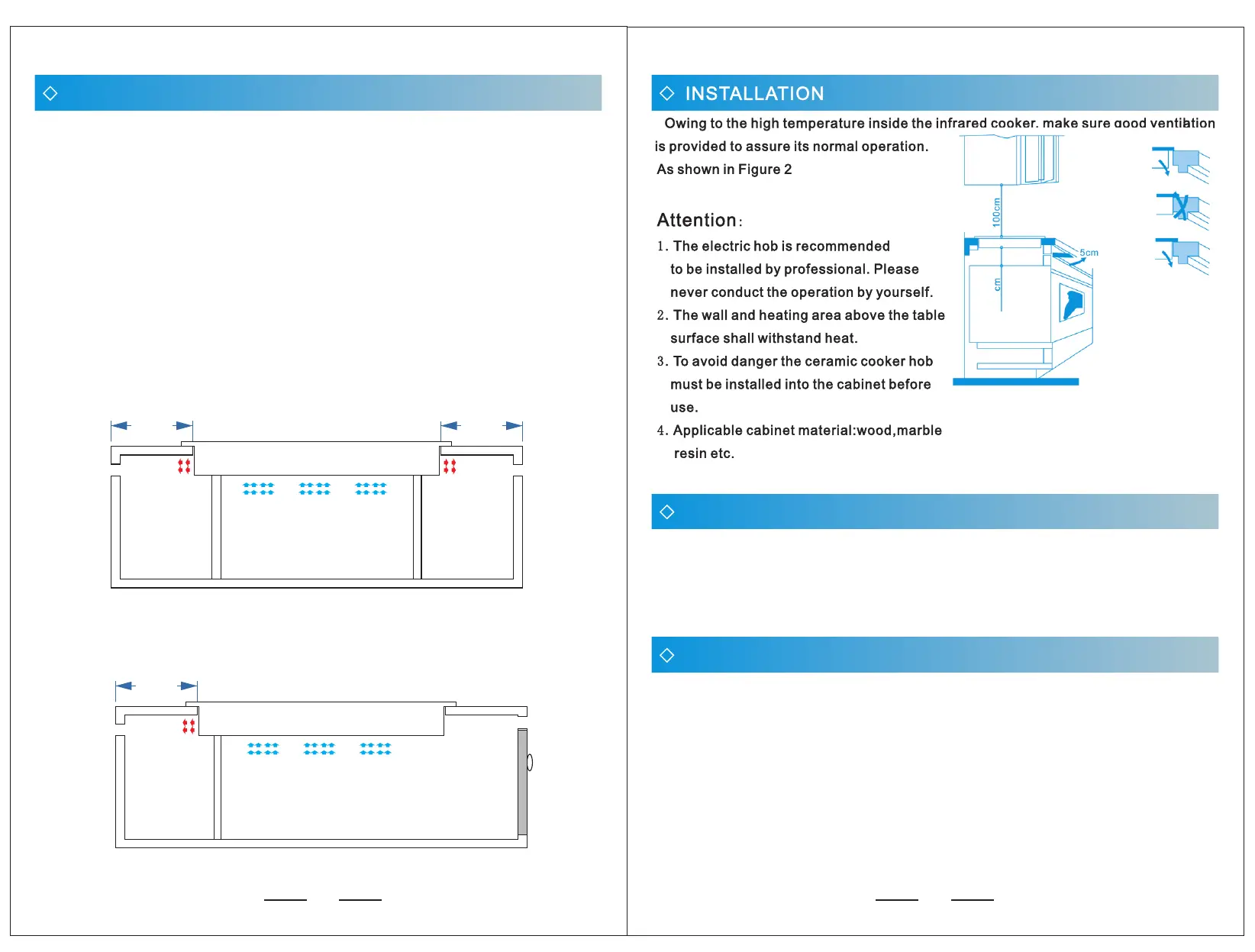

During operation, the surface temperature of the crystal plate is very high.

Please do not touch it to avoid scalding.The appliance shall not be operated

by means of an external timer or independent remote control system.

MATTERS NEEDING ATTENTION

FAULT CODE

E0------- no pot

E1------- The voltage is lower than 90.

E2------- Excessive voltage (voltage higher than 270)

E3------- Furnace surface overtemperature or sensor damage short circuit

E4------- Furnace surface sensor open

E5-------IGBT overtemperature or fan damage does not work

E6------- The IGBT sensor is open

E8------- The control board is connected to the main power supply board

Voltage adaptation range: 90-- 270 VOLTS

Loading...

Loading...