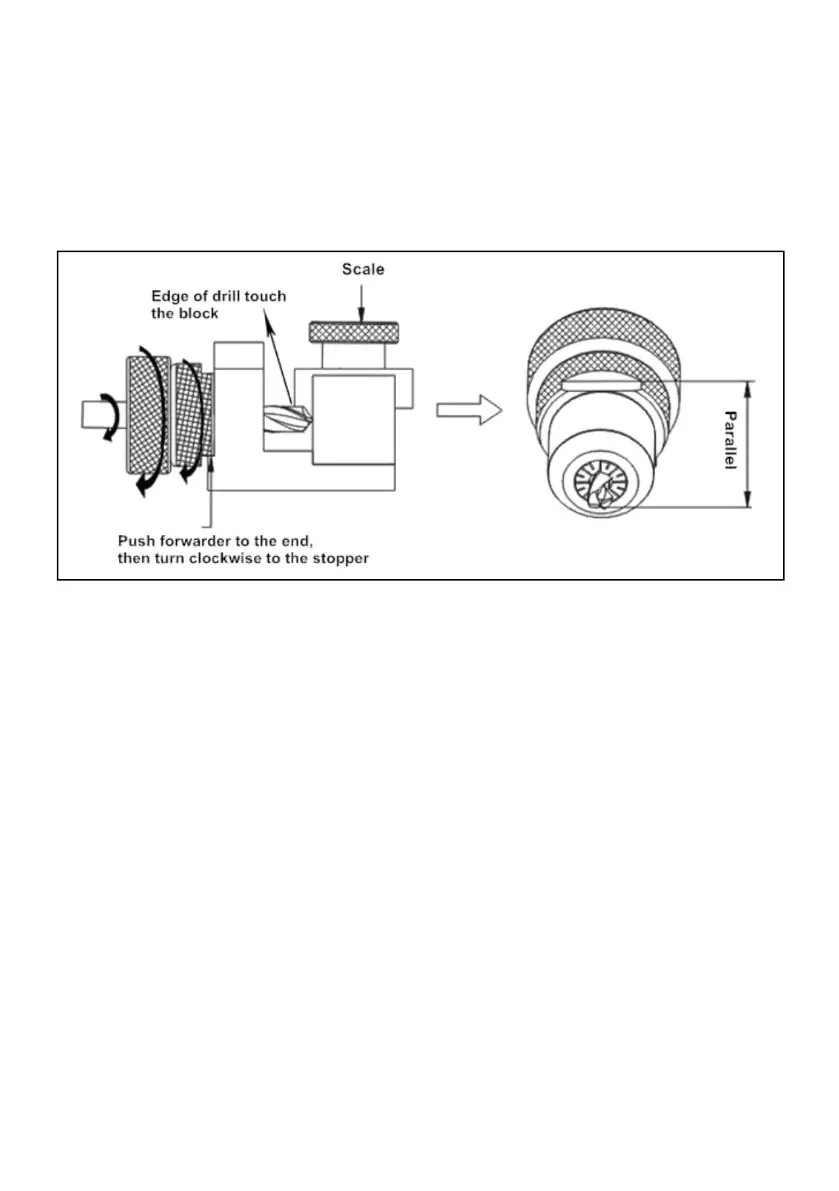

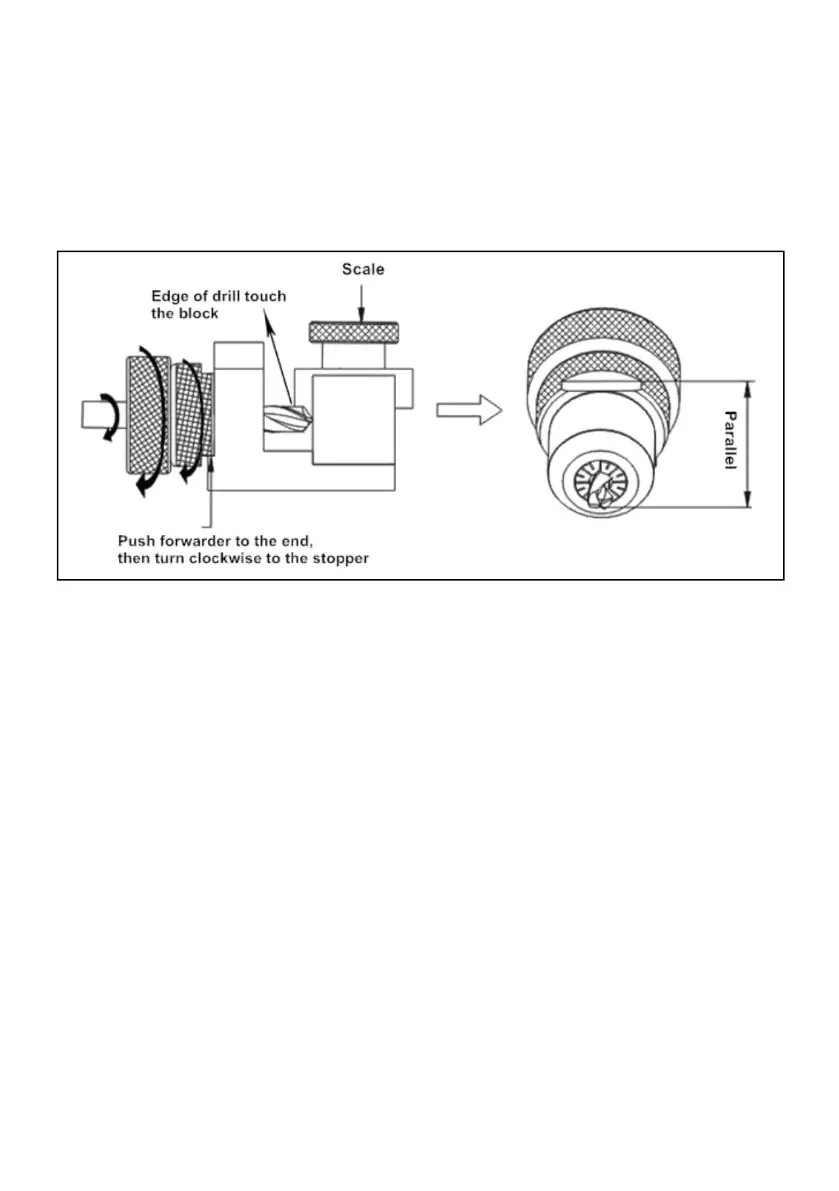

3. Plug the drill to the end and turn it clockwise to the end.

4. Turn the chuck set clockwise to the end and tightens it

5. Turn the chuck set a little to the anti-clockwise and taking it out gently.

※ Make sure the cutting lip of drill is parallel with the slot of clamping

nut before grinding job started. If it is not parallel, adjust it again.

Attention: If the cutting lip is downward, must increase the scale of web

adjustment shelf. If it is upward, please decrease the scale of the web

adjustment shelf.

When the flute length of a drill becomes shorter, the web thickness of a drill

would become thicker. So, for the same diameter of drills, the shorter

length of a drill, the higher scale of web adjustment shelf need to be

increased.

C. Grind the point angle

Turn the power switch on and wait until the motor rotation is stable (about

10 seconds), put the chuck set into the point angle grinding shelf.

The slot of clamping nut must fit with the two pins of the grinding shelf.

Insert the drill gently into grinding shelf until reach the grinding wheel.

Grind the drill by moving left and right until the grinding sound disappears.

And then turn to the other side, do the same to grind the drill.

* The grinding size of drill is 2mm-13mm(15mm)

Loading...

Loading...